Oscillating overturning device for symmetrical parts of autobody

A technology for turning over devices and car bodies, which is applied in the direction of feeding devices, positioning devices, storage devices, etc., which can solve the problems of lower automation speed of the whole line, low equipment utilization rate, and impact on production tempo, so as to reduce the cost of special equipment, The device is simple and practical, and the effect of meeting the production requirements of high efficiency and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

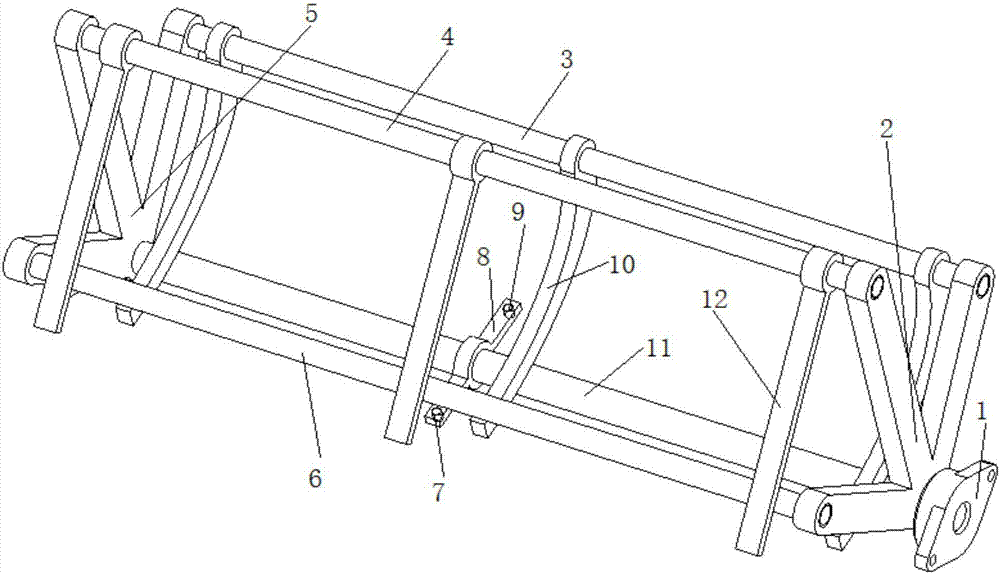

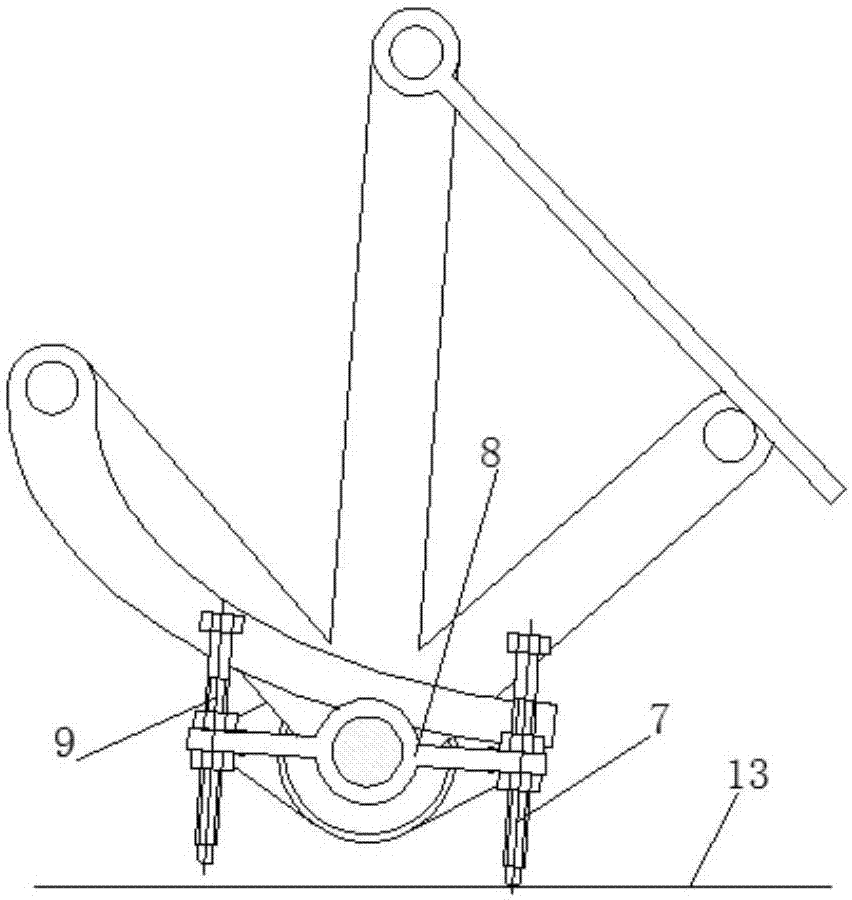

[0024] Such as figure 2 As shown, the structure of the device of the present invention is as follows: it includes two bearing seats 1 arranged on the left and right sides of the lower mold, a support shaft 11 is arranged between the two bearing seats 1, and a limiting support shaft is arranged on the support shaft 11 11 Limiting mechanism of the rotation range; the first connecting piece 2 and the second connecting piece 5 are fixed on the supporting shaft 11; the first connecting piece 2 and the second connecting piece 5 are respectively adjacent to the bearing housings 1 on both sides. Also be fixed with a turning bar 4, a front supporting bar 6 and a rear supporting bar 3 between the first connecting piece 2 and the second connecting piece 5, described turning over bar 4, front supporting bar 6 and rear supporting bar 3 mutually ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com