Six-wheel-structure-type AGV trolley

A structural and trolley technology, applied in the direction of motor vehicles, transportation and packaging, etc., can solve the problems of limited space and achieve the effect of increasing load-bearing and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

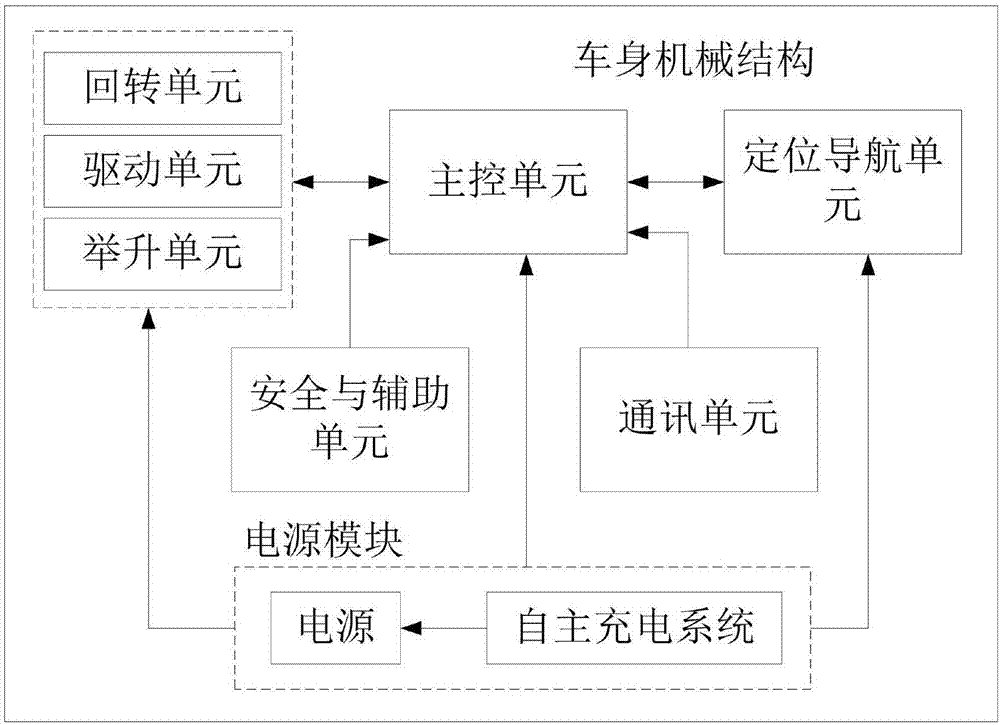

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

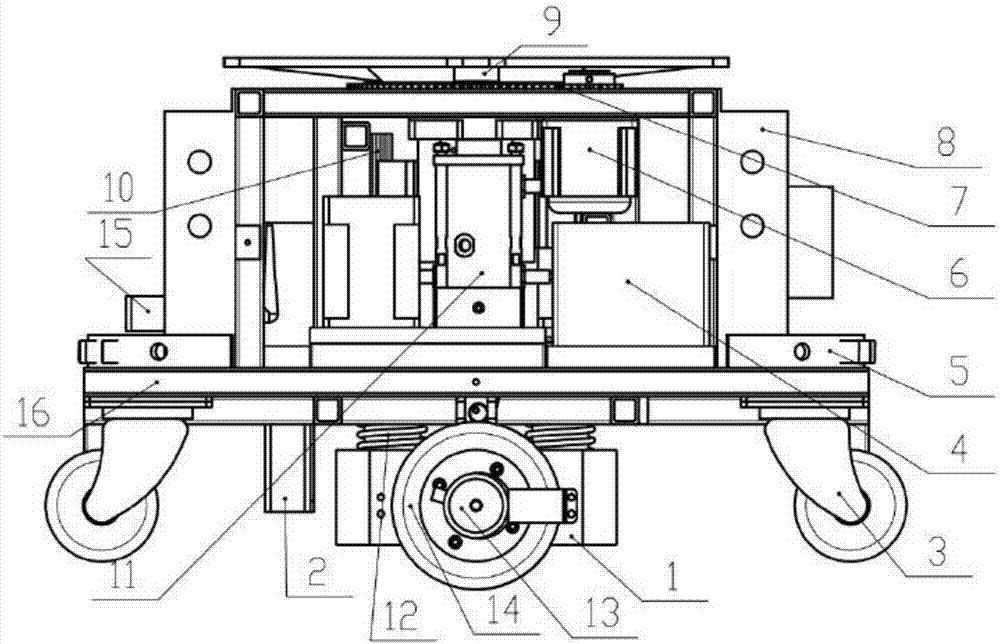

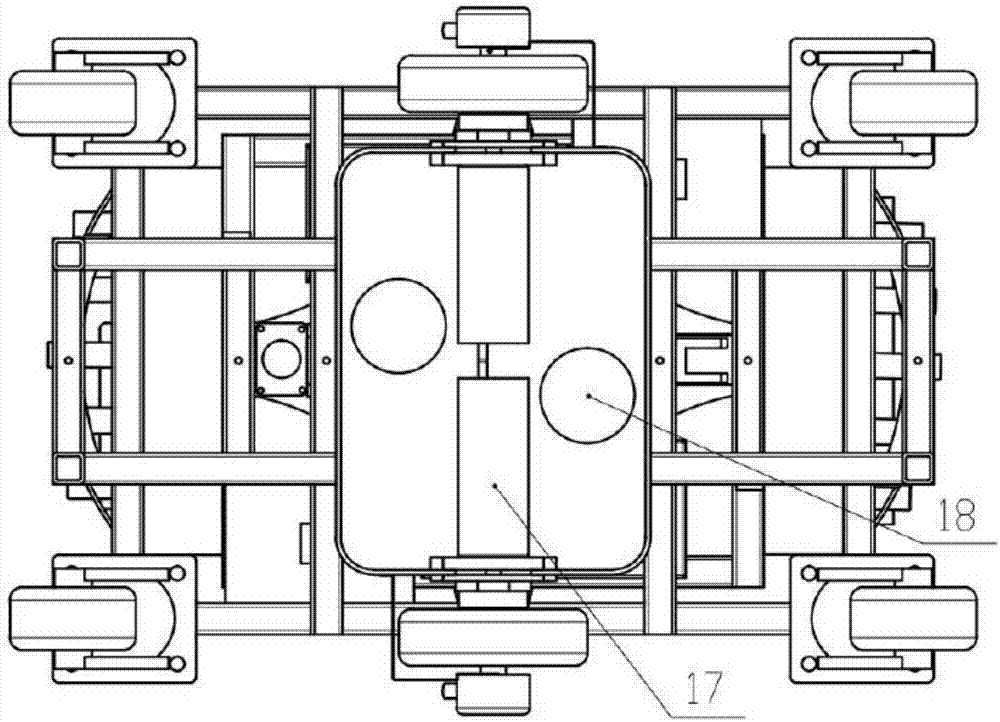

[0017] refer to figure 1 , figure 2 , image 3 and Figure 4 , the present invention includes a drive structure assembly 1, a camera 2, a supporting universal wheel 3, a battery 4, a safety anti-collision bracket 5, a rotary motor 6, a rotary mechanism assembly 7, a PLC control bracket 8, a tray assembly 9, guide rails and sliders Assembly 10, lifting electric cylinder assembly 11, suspension system assembly 12, encoder 13, drive wheel 14, wireless router 15, frame assembly 16, drive motor 17 and guide column assembly 18; the front and rear of the left and right sides of the frame assembly 16 Both ends are equipped with supporting universal wheels 3, and the middle part of the bottom surface of the frame assembly 16 is provided with a suspension system assembly 12. The lower end of the suspension system assembly 12 is provided with a drive wheel 14 through the drive structure assembly 1, and an encoder 13 is provided in the middle of the drive wheel 14. A camera 2 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com