Refrigerating system

A refrigeration system and condenser technology, applied in the field of refrigeration systems, can solve problems such as air-supply mixing loss, and achieve the effects of reducing mixing loss, improving heating performance, and improving energy efficiency levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

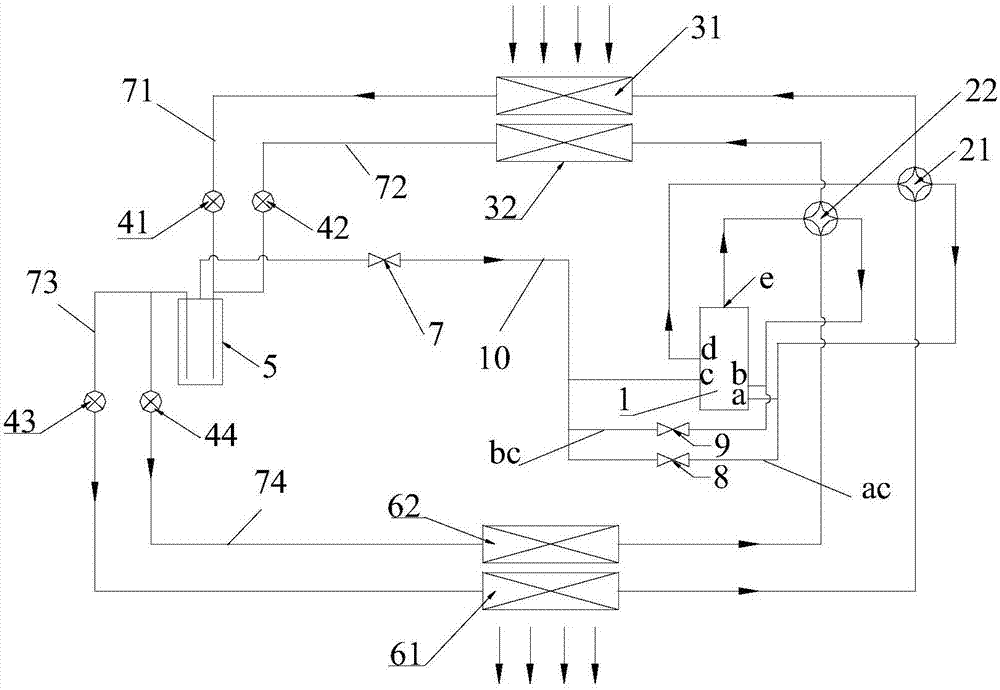

[0039] Such as figure 1 As shown, the present invention provides a refrigeration system, which includes a compressor 1, a throttling device, an evaporating device, and a condensing device;

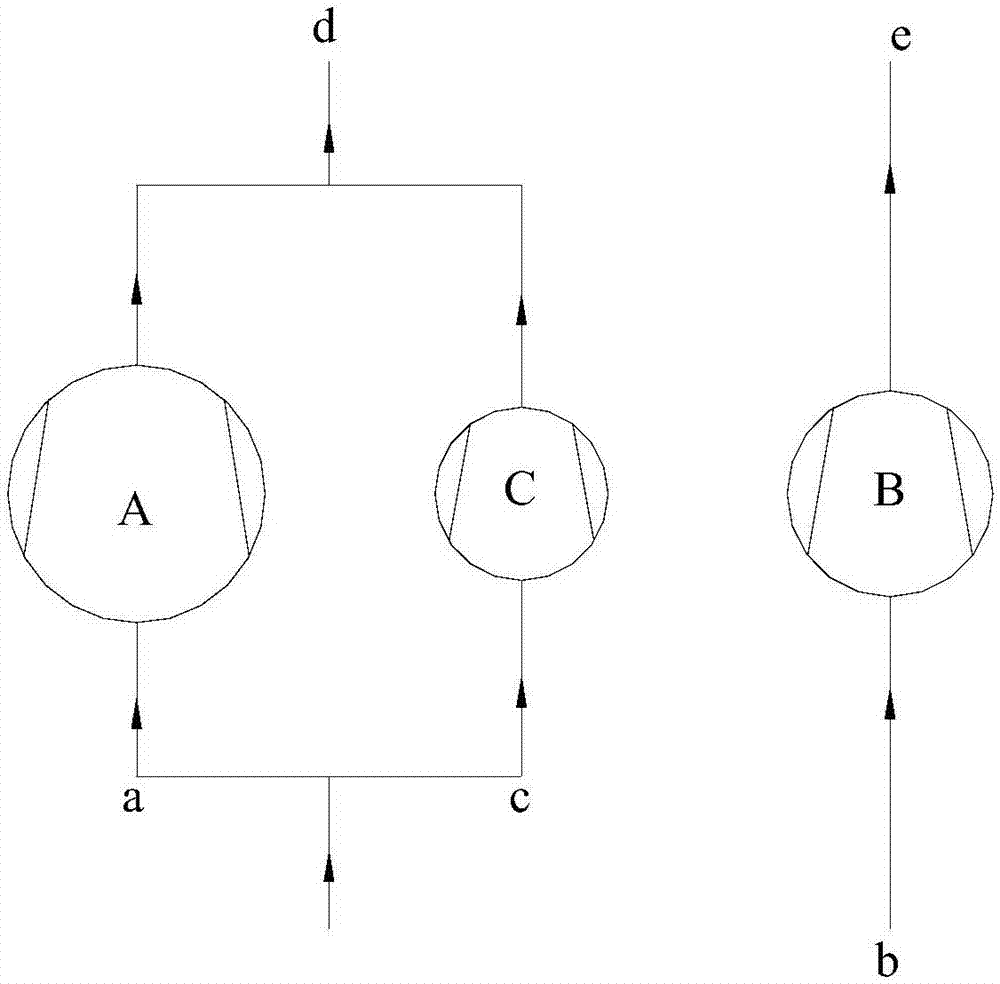

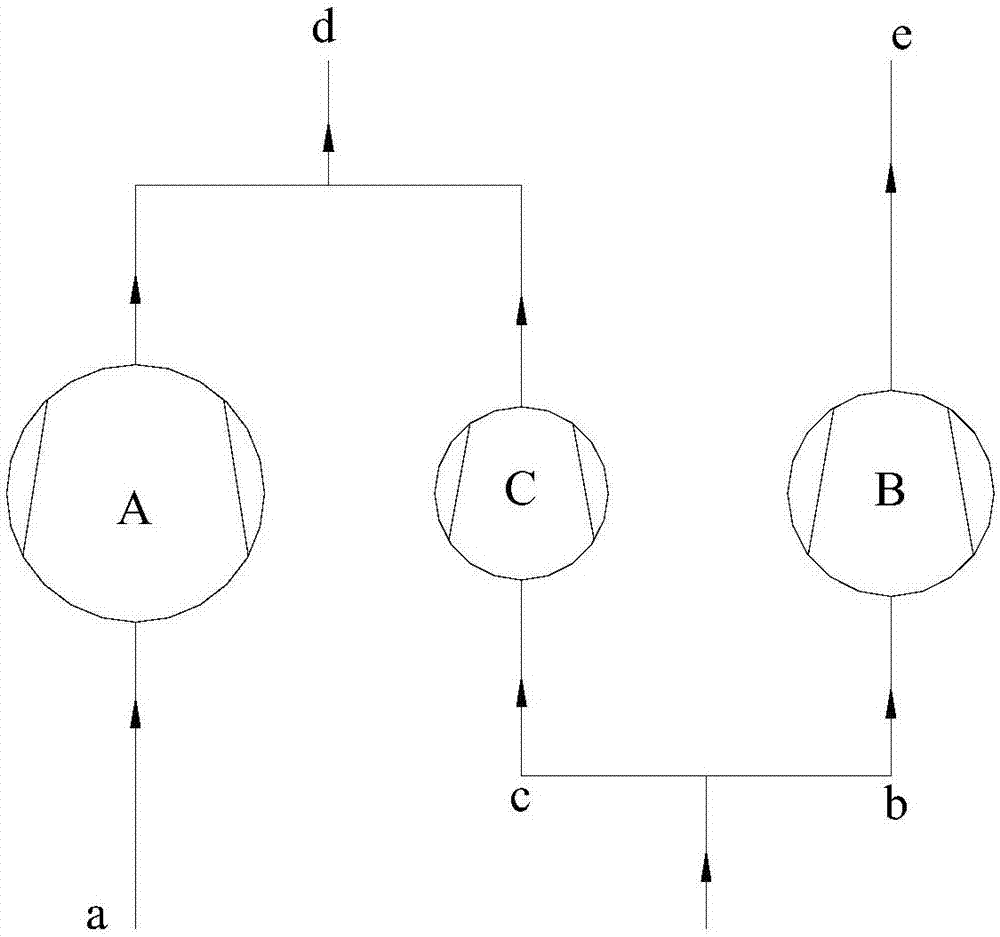

[0040] The compressor includes two or more independent compression chambers;

[0041] It also includes more than one switching compression chamber (the switching compression chamber and the above two or more compression chambers are also independent of each other), one or more supplementary ports, and a supplementary gas branch 10 located outside the compressor, so The air supplement port can be connected to the air supplement branch 10, the suction end of the switching compression chamber is connected with the air supplement port, and the discharge end is connected with the exhaust port of the compressor.

[0042] By adding more than one switching compression chamber and more than one supplementary air port on the basis of the original parallel single-stage two-cylinder compressor, and connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com