Telescopic motor rotor winding device

A technology of motor rotor and winding device, applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve problems such as affecting product quality, winding separation, decoupling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

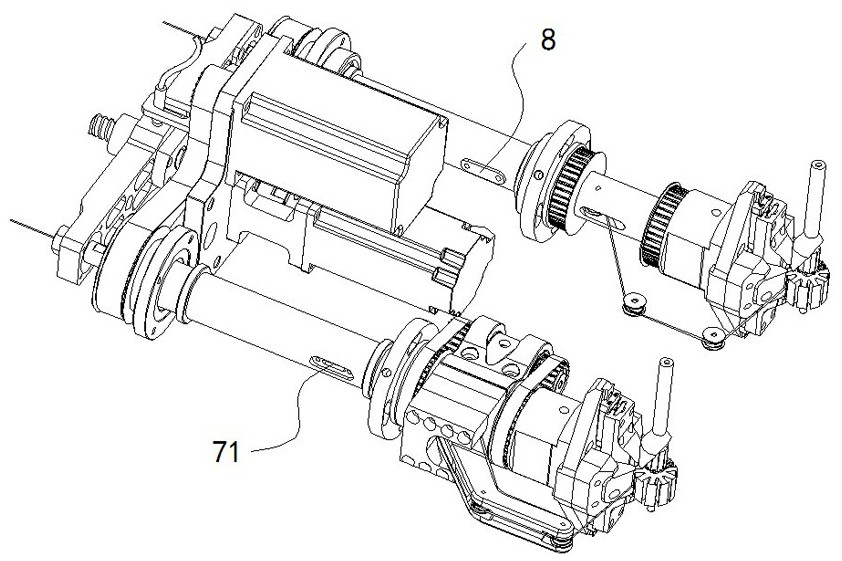

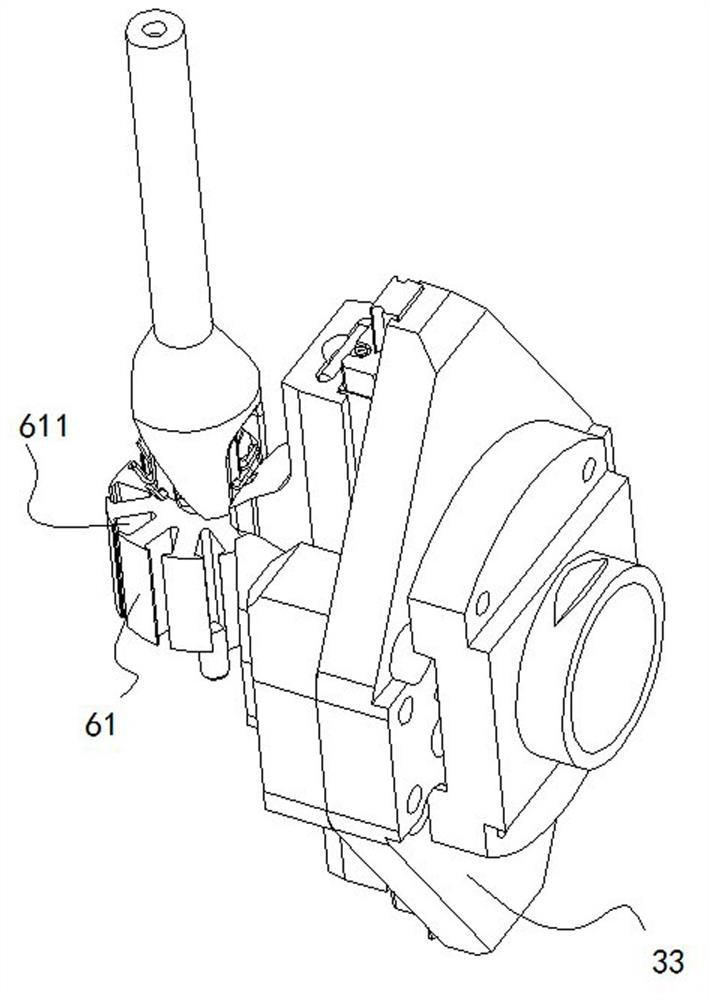

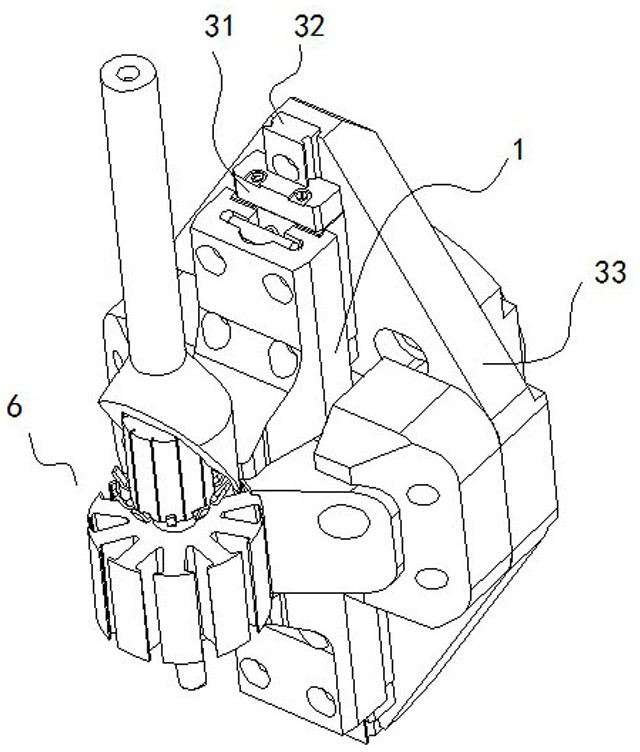

[0031] Please refer to Figure 1 to Figure 15 , the telescopic motor rotor winding device in the figure includes a first winding guide 1, a second winding guide 2, a guide sliding mechanism 3, a guide reset mechanism 4, and a guide telescopic Drive mechanism 5. The function of the first winding guide 1 and the second winding guide 2 is to lead the copper wire out from the fly fork 10 and wind it on the iron core 61 in a superimposed state, even if the copper wire has a height difference and is wound on the iron core of the rotor 6. On the core 61, the copper wire can be prevented from detaching from the hanging groove 611 due to the increased winding space through such a winding method. The function of the guide sliding mechanism 3 is to make the above-mentioned two guides slide up and down to realize telescopic action; the function of the guide reset mechanism 4 is to reset the above-mentioned two guides; The motion is converted into an up and down motion of the two guides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com