Noise reduction device for cutting machine

A cutting machine and noise reduction technology, applied in shearing devices, accessories of shearing machines, metal processing equipment, etc., can solve the problems of no noise reduction protection, environmental pollution, impact, etc., to ensure accuracy and avoid environmental pollution , to ensure the effect of no leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

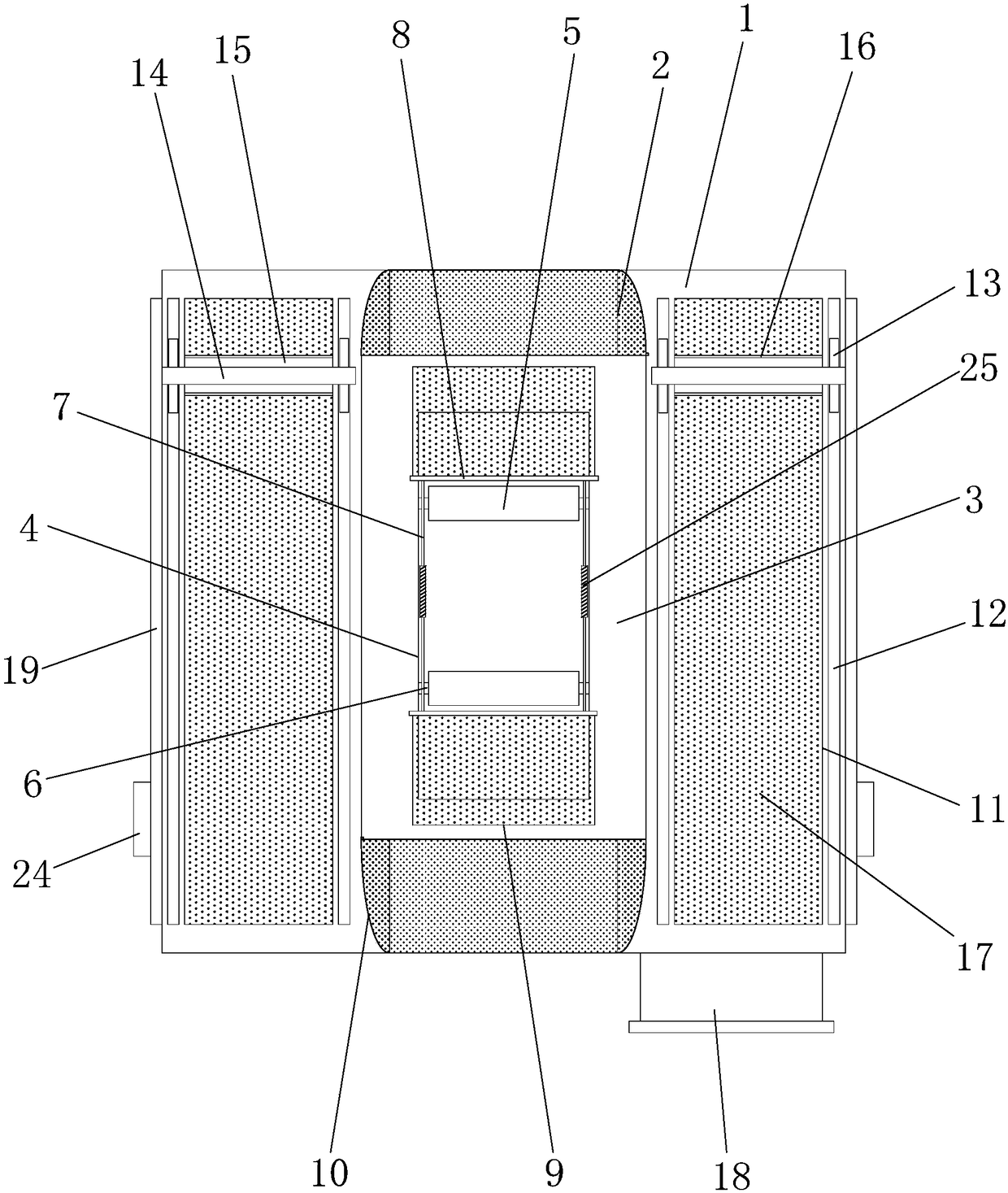

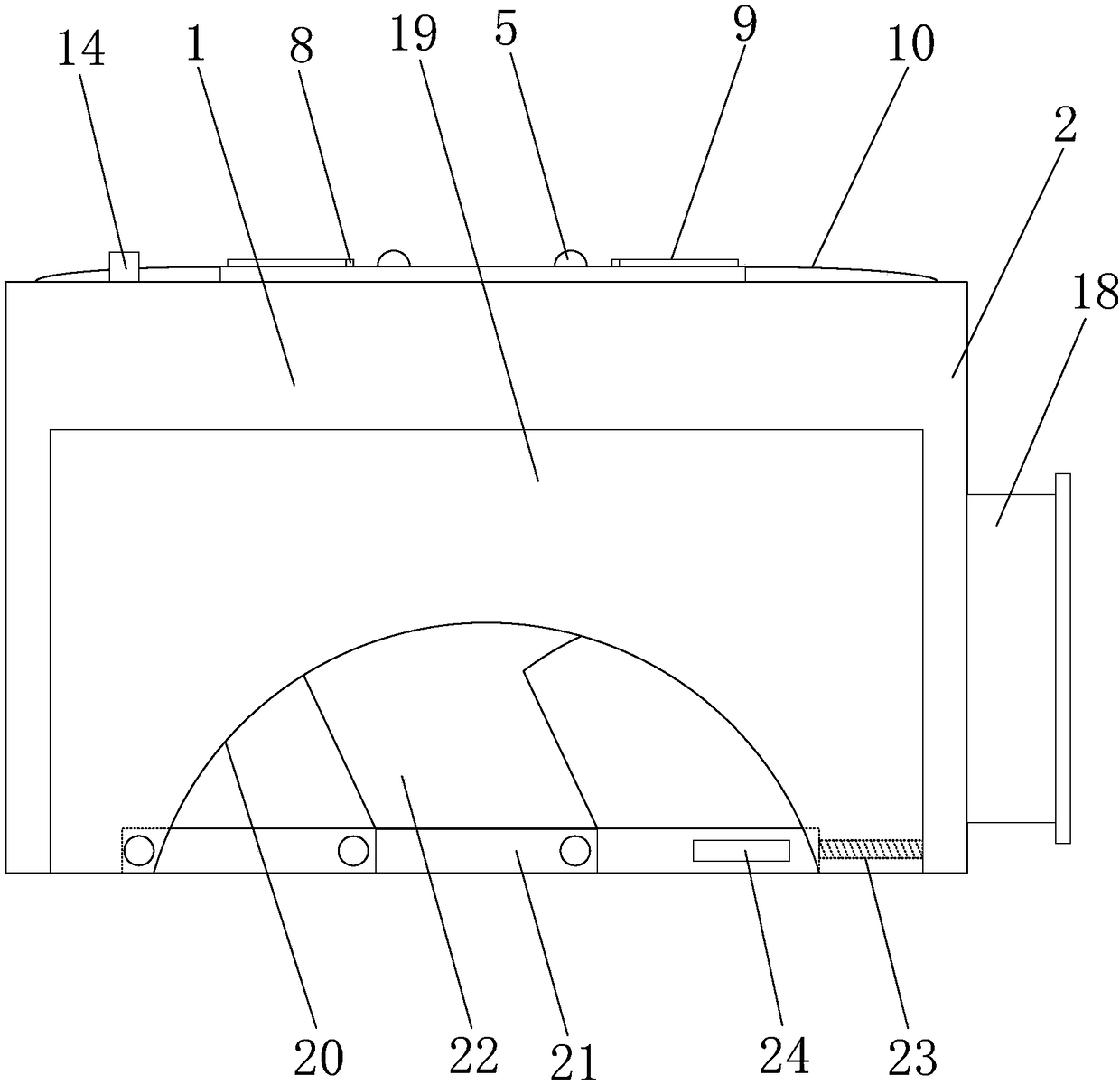

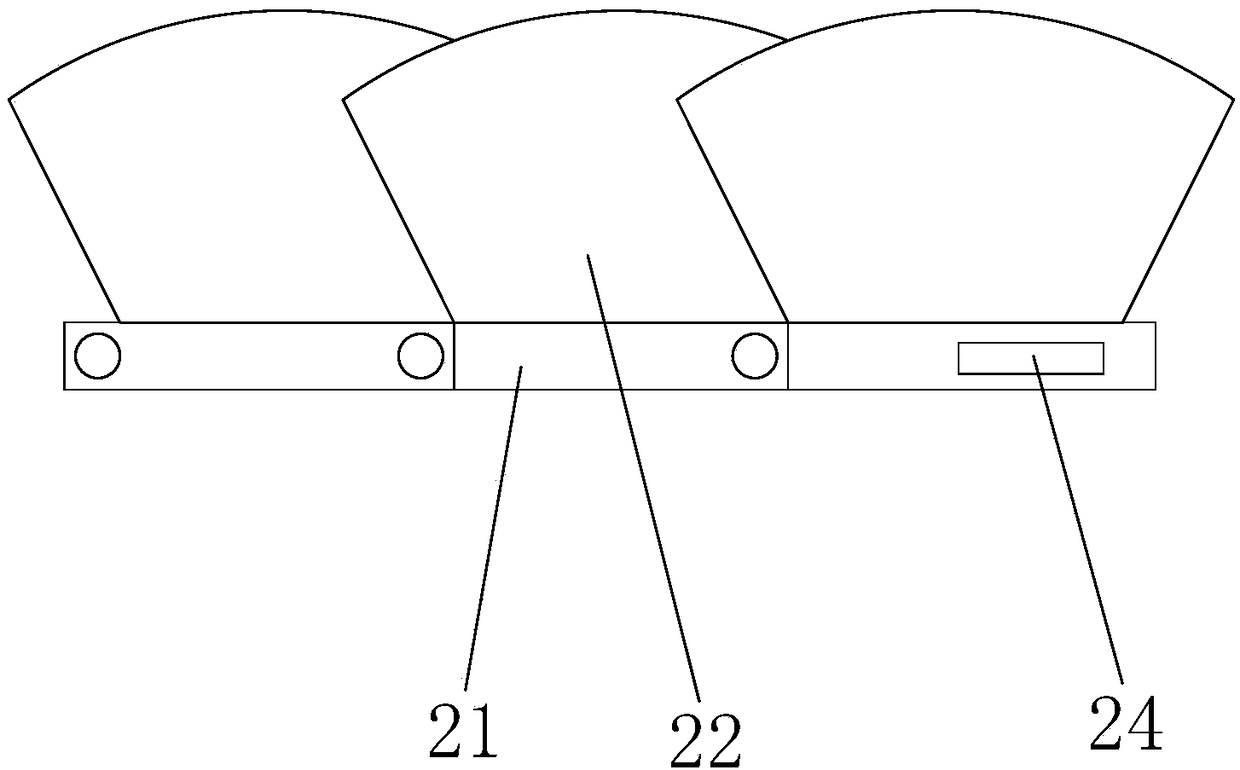

[0013] Such as Figure 1-3 As shown, the invention discloses a noise reduction device for a cutting machine comprising: a square casing 1, a sliding cover 3 and two side baffle mechanisms respectively installed on the left and right sides of the square casing 1; The bottom of the casing 1 is open, and the top is provided with a strip window 2; a snap-in chute is provided on the sides of the left and right length edges of the sliding cover plate 3; the sliding cover plate 3 is installed on the strip window 2 on the top, and the left and right two buckle chute are slidingly buckled on the left and right length edges of the strip window 2; between the front width edge of the strip window 2 and the front width edge of the sliding cover 3 And a plastic film 10 is connected between the rear width edge of the strip window 2 and the rear width edge of the sliding cover plate 3; the sliding cover plate 3 is provided with a rectangular handle hole 4 for the cutter handle to pass through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com