Rubber processing equipment for rubber hammer production

A processing equipment and rubber hammer technology, applied in the field of manufacturing and processing, can solve the problems of easy falling off of rubber hammers, waste of manpower and material resources, hidden dangers, etc., and achieve the effects of ensuring work safety, increasing service life, and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

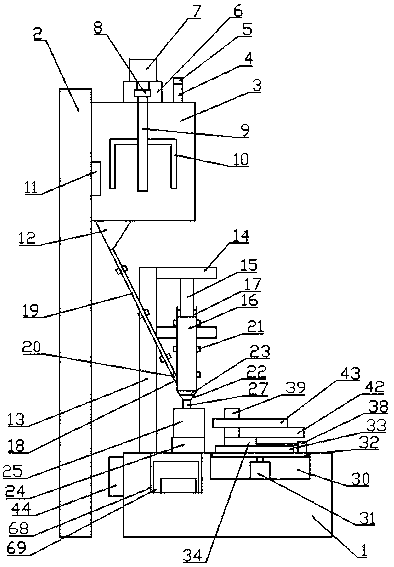

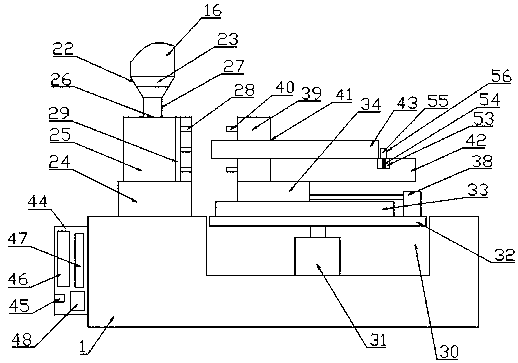

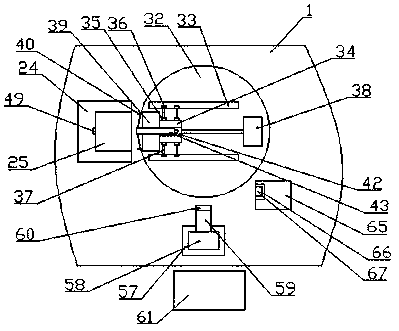

[0022] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6As shown, a rubber processing equipment for producing rubber hammers includes a base 1, the base 1 is fixedly installed on the ground, the base 1 is provided with a mixing mechanism, and the mixing mechanism is fixedly installed on the base 1- The support platform 2 on the side ground, the mixing tank 3 fixedly installed on the side above the support platform 2, the feeding port 4 located on the outer upper surface of the mixing tank 3, the sealing cover 5 fixedly installed on the feeding port 4, The frame 6 fixedly installed on the outer upper surface of the mixing tank 3, the rotating motor 7 fixedly installed on the outer upper surface of the frame 6, the shaft sleeve 8 of the rotating end suit of the rotating motor 7 extending into the frame 6, and the shaft The sleeve 8 is fixedly connected and extends into the rotating shaft 9 in the mixing tank 3, the U-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com