A suspension-arch composite system bridge

A technology for bridges and cantilevered arches, applied in the field of suspended arch composite bridges, can solve the problems of quality limitation, rope tensile elastic bridge rigidity, etc., and achieve the effect of reducing burden and requirements, improving rigidity and increasing bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

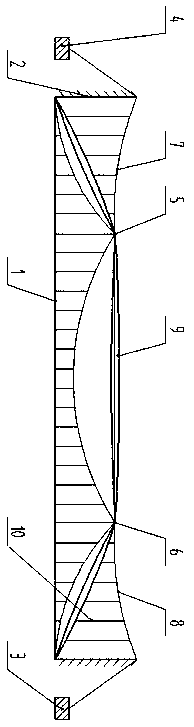

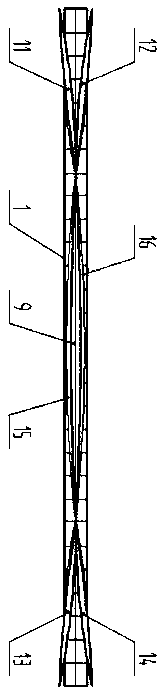

[0034] As shown in the accompanying drawings of the description, a bridge with a suspension arch combination system includes a bridge span 1, a cable tower 2, an anchor 2 3, an anchor 4, a support beam 17, a fastening beam frame 18, a cable hole 19, a bearing Point 2 5, Supporting point 1 6, supporting arch suspension cable 1 7, supporting arch suspension cable 2 8, horizontal arch rod 9, ballistic structure sling 10, inclined arch rod 1 A 11, inclined arch rod 1 B 12, oblique arch rod 1 Arch pole 2 A 13, inclined arch pole 2 B 14, supporting bridge suspension cable A15, supporting bridge suspension cable B 16; both ends of supporting arch suspension cable 1 7 are fixed to bearing point 1 6, anchoring point 1 4, supporting arch suspension cable Both ends of No. 8 are fixed on bearing point No. 5 and anchor No. 3, the overlapping sections of the two bracket suspension cables 7 and 8 pass through the cable hole 19, the non-overlapping section is erected on the cable tower 2, and ...

Embodiment 2

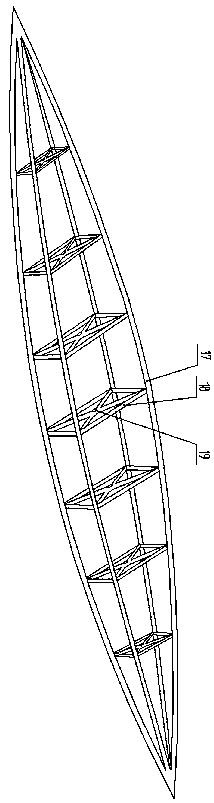

[0036] Such as Figure 3 to Figure 6 As shown, a shuttle-shaped arch used in Embodiment 1 includes a support beam 17 and a fastening beam frame 18, and the horizontal cable-shaped arch will increase the cable hole 19; its structure is to divide the traditional arch body into a The above beams are connected by several fastening beams 18 at a certain distance to form a shuttle-shaped structure with a wide middle and gradually narrowing towards the two ends. The plane where the fastening beams 18 are located is perpendicular to the axis, and the axis is the line connecting the two ends of the rod. , the fastening beam frame 18 is composed of an outer fastening beam and an inner fastening beam, but when the number of support beams 17 is two, the fastening beam frame 18 is only the only fastening beam and does not distinguish between the outer and the inner, but it can be composed of several This planar bar body is connected in parallel to form a shoulder-carrying three-dimensional...

Embodiment 3

[0038] Such as Figure 7 As shown, a ballistic structure sling 10 for the suspension arch bridge of Embodiment 1 includes a rope 20, a casing 21 and a pipe buckle block 22; the outside of the rope 20 is covered with a casing 21, and the rope 20 passes through the two ends of the casing 21 and connects with the pipe buckle block 22, and the outer periphery of the rope 20 is close to the inner periphery of the casing 21 and can be moved, and there is a force pushing the pipe buckle block 22 at both ends of the casing 21 The structural design principle of bullet-resistant structure sling 10 is based on: the extruding deformation of material is less than tensile deformation, thereby when sling bearing tension is less than sling inner rope 20 prestressed tensions, deformation is minimal, can strengthen bridge body rigidity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com