Novel combustor tube head structure

A technology of burners and pipe heads, which is applied in the direction of burners, burners burning powder fuel, combustion methods, etc., can solve the problems of burner performance degradation, uneven thermal expansion of pipe heads, displacement of mating surfaces, etc., to ensure stable performance , stable compensation performance, the effect of stable compensation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

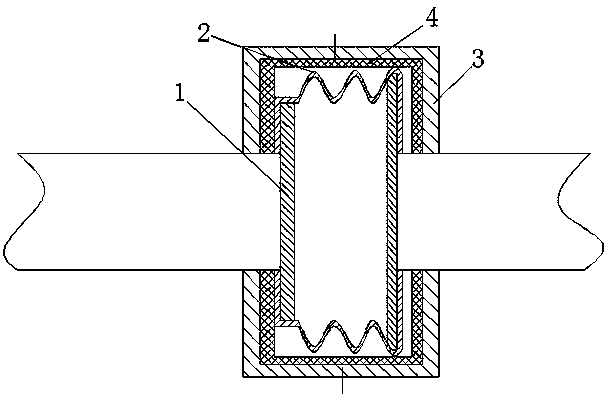

[0014] The two pipe heads 1 of the present invention have a flange structure, and the connection between the two pipe heads 1 is realized by an elastic pipe 2. The connecting head 3, the connecting head 3 and the corresponding pipe head 1 form the positioning of the elastic tube 2, and the two connecting heads 3 are butted to form a fixed connection.

[0015] At the same time, the connecting head 3 forms a limit to the elastic tube 2 from the circumferential direction.

[0016] The elastic tube 2 is in the form of a bellows structure.

[0017] An elastic pad 4 is arranged between the elastic tube 2 and the connecting head 3 .

[0018] The working process of the present invention is as follows: the present invention first clamps the elastic tube 2 on the inner end of the corresponding pipe head 1, then sets the corresponding connecting head 3 on the outer end of the pipe head 1, and the connecting head 3 and the pipe head 1 will elastically The positioning of the tube 2 is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com