Detection method of inter-turn pressure during hot-press forming process of centripetal magnetic pole coil of hydro-generator

A technology of hydro-generator and magnetic pole coil, applied in the direction of measuring force, measuring device, instrument, etc., can solve problems such as uncontrollability of hot-pressing forming of centripetal magnetic pole coil, and achieve the effect of high reliability and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

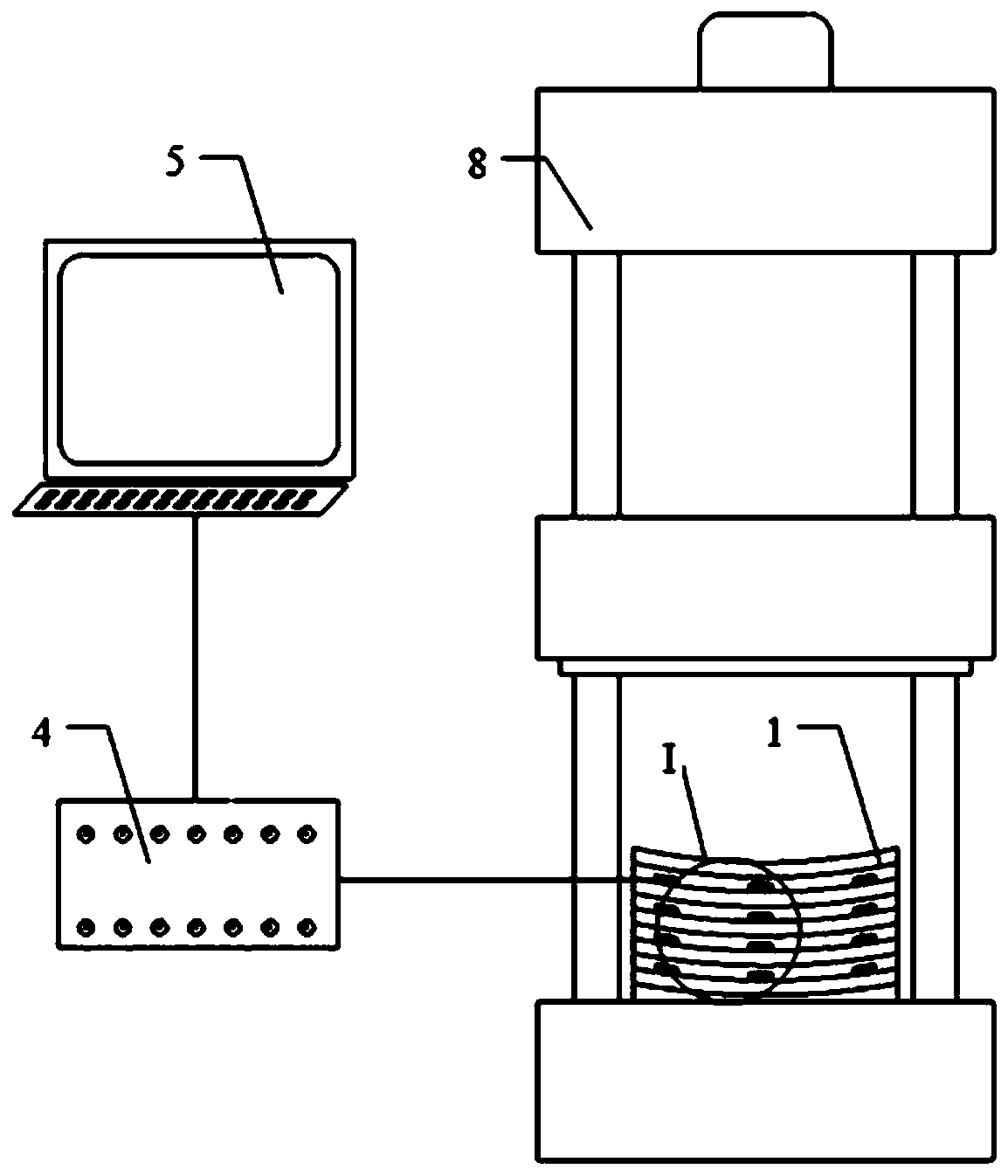

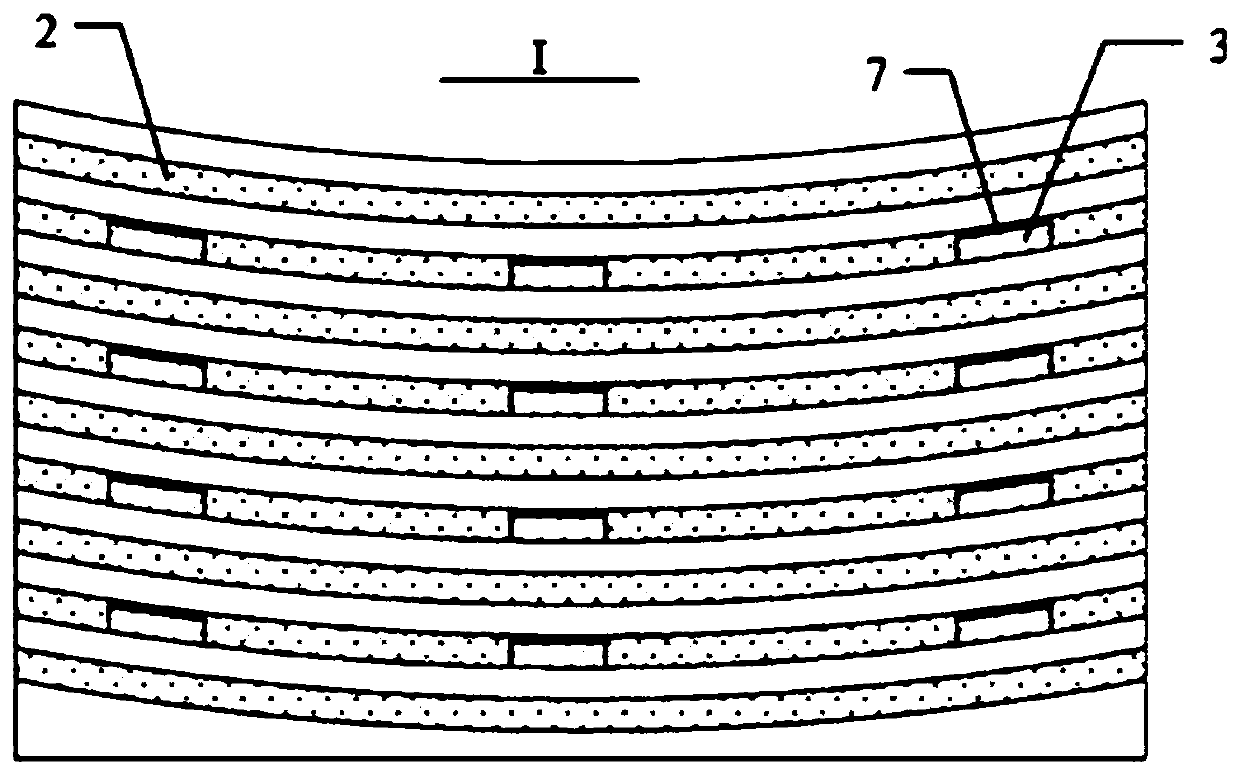

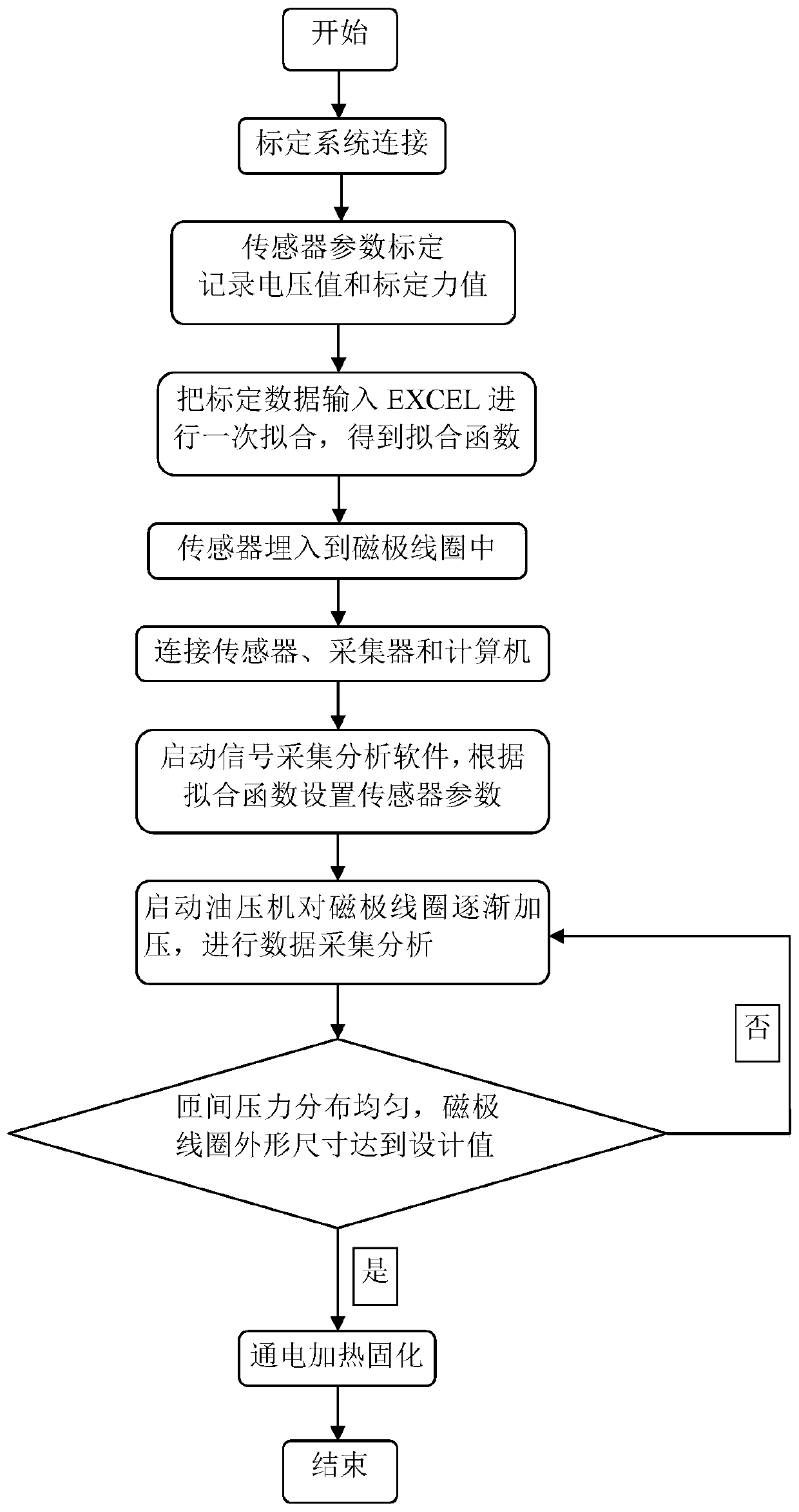

[0013] The invention relates to a method for detecting the inter-turn pressure during the hot-press forming process of the centripetal magnetic pole coil of a hydraulic generator, such as image 3 As shown, the specific technical solution is: select detection equipment: according to the centripetal magnetic pole coil 1 inter-turn insulation 2 thickness, select a high temperature resistant film pressure sensor 3 with an appropriate thickness, a data collector 4 that can be connected to a 0-5V DC voltage, and a device equipped with A computer suitable for signal analysis software5;

[0014] a) Calibration of the high temperature resistant thin film pressure sensor 3: connect the high temperature resistant thin film pressure sensor 3, the data collector 4 and the computer 5, such as figure 1 As shown, start the data collector 4 and the computer 5, put the high temperature resistant thin film pressure sensor 3 on a small press for calibration, use EXCEL to perform a fitting on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com