Intelligent fire-fighting sprinkler head

A sprinkler and fire-fighting technology, which is applied in fire rescue and other directions, can solve the problems of glass ball automation equipment that cannot be connected efficiently and concisely, it is difficult to realize the first-time work of fire sprinklers, and fire detection feedback is not timely, so as to reduce the possibility of sprinkler failures performance, solve the interference of blocking objects, and the effect of low installation height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

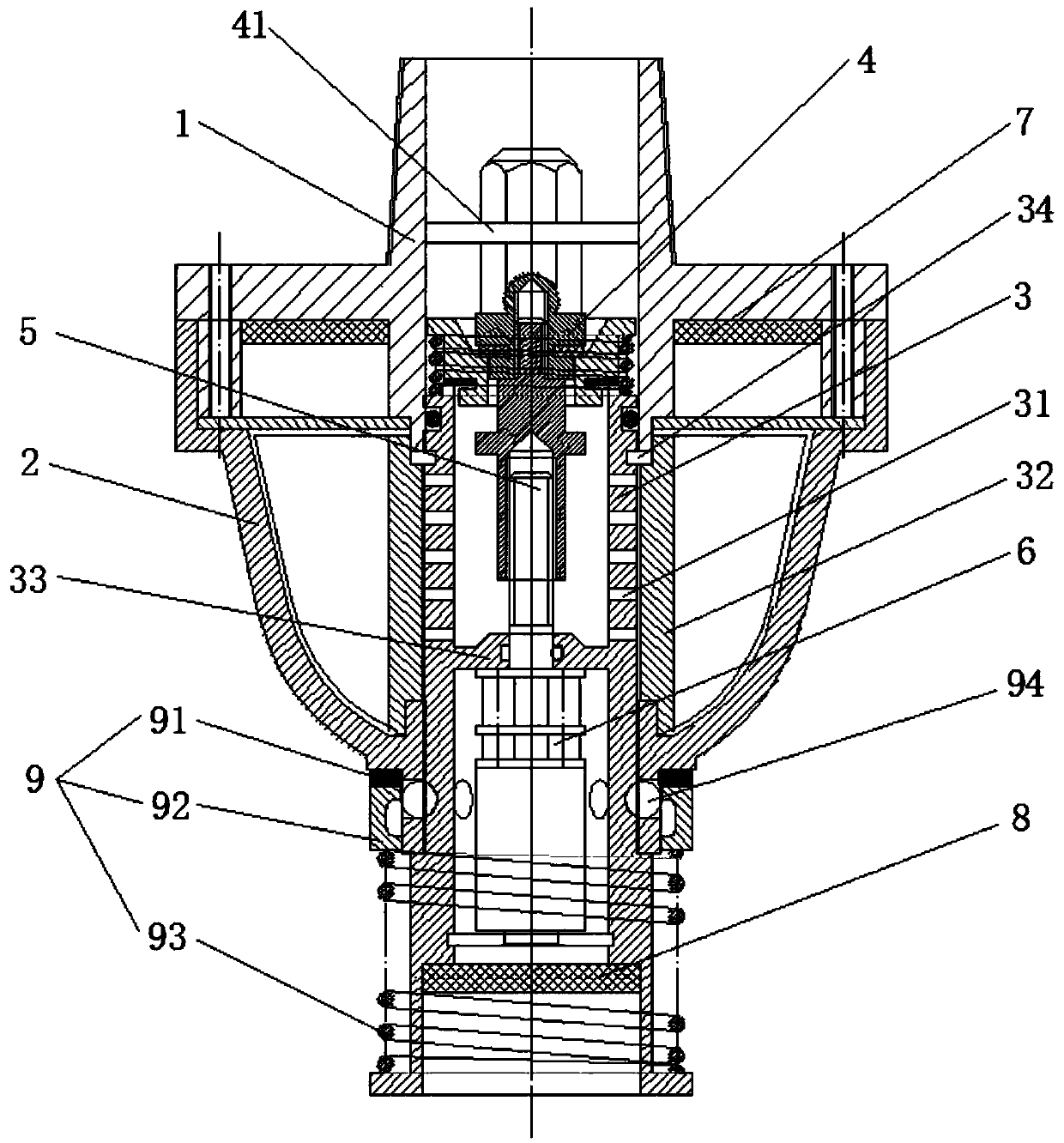

[0058] A kind of intelligent fire-fighting sprinkler head, it is characterized in that: comprise a nozzle base 1, and described nozzle base 1 is provided with water nozzle; A sealing seat 4, is positioned at described water nozzle, and described sealing seat 4 is relatively The nozzle is sealed backwards; an outer cover 2 is connected with the nozzle base 1; an emergency start pipe 3 is clamped and fixed with the nozzle base 1 or the outer cover 2, and is used to support the sealing seat 4. The emergency start pipe 3 A number of water outlet holes 31 are arranged on the top; a temperature sensing component 9 is clamped between the emergency start tube 3 and the outer cover 2, and is used to limit the position of the emergency start tube 3. The temperature sensing component 9 includes a temperature sensing component Part 91; a starting device 6, which is fixedly connected with the nozzle base 1, the outer cover 2 or the emergency starting tube 3, and a transmission part 5 for tr...

Embodiment 2

[0064] Further optimization on the basis of embodiment one,

[0065] The emergency start tube 3 is located directly below the water spout, and one end of the emergency start tube 3 is located in the water spout, the emergency start tube 3 is pierced and clamped on the outer cover 2, and the temperature sensing component 9 It is located outside the emergency start pipe 3 . The sealing seat includes a plurality of sealing seats that are matched and sealed step by step, and a booster spring is arranged between the sealing seat of the last stage and the emergency start tube.

[0066] The emergency starting pipe 3 is provided with a water spinner 32 outside, and the water spinner 32 is located in the outer cover 2 .

Embodiment 3

[0068] Further optimization on the basis of Embodiment 1 or 2, integrated mode: also includes a detector and a control board, the control board is connected to the detector and the starting device 6, and the detector is located at the nozzle base 1, the outer cover 2 or the emergency start In the pipe 3, one or more detectors are provided, and the detectors are one of smoke detectors, temperature detectors, gas detectors, infrared detectors, ultraviolet detectors, and flame detectors or more.

[0069] The outer cover 2 and the spray head base 1 are connected to form a receiving chamber 1 , and a number of ventilation holes are arranged on the cavity of the receiving chamber 7 . A detector and a control board are arranged in the accommodating chamber one 7 . The lower end of the emergency starting tube 3 is provided with a second accommodating chamber 8, and a detector is arranged in the second accommodating chamber 8.

[0070] The outer cover 2 and the nozzle base 1 are scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com