Compensation structure of die pressed casting aluminum

A compensation structure and die-casting technology, applied in the field of casting molds, can solve the problems of local position defects of castings, lower product production quality, insufficient pressure of aluminum liquid, etc., so as to improve production quality and avoid local insufficient pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

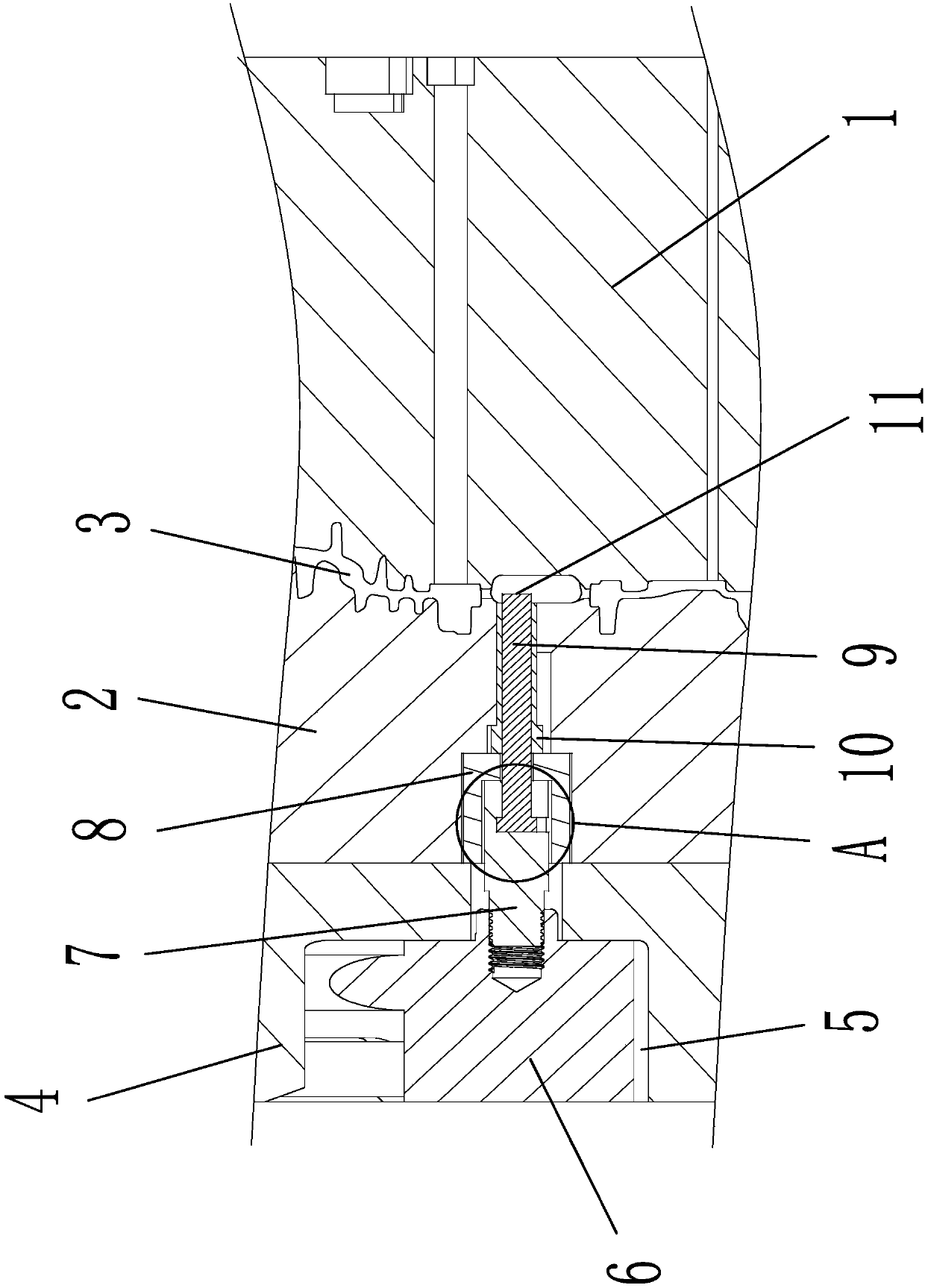

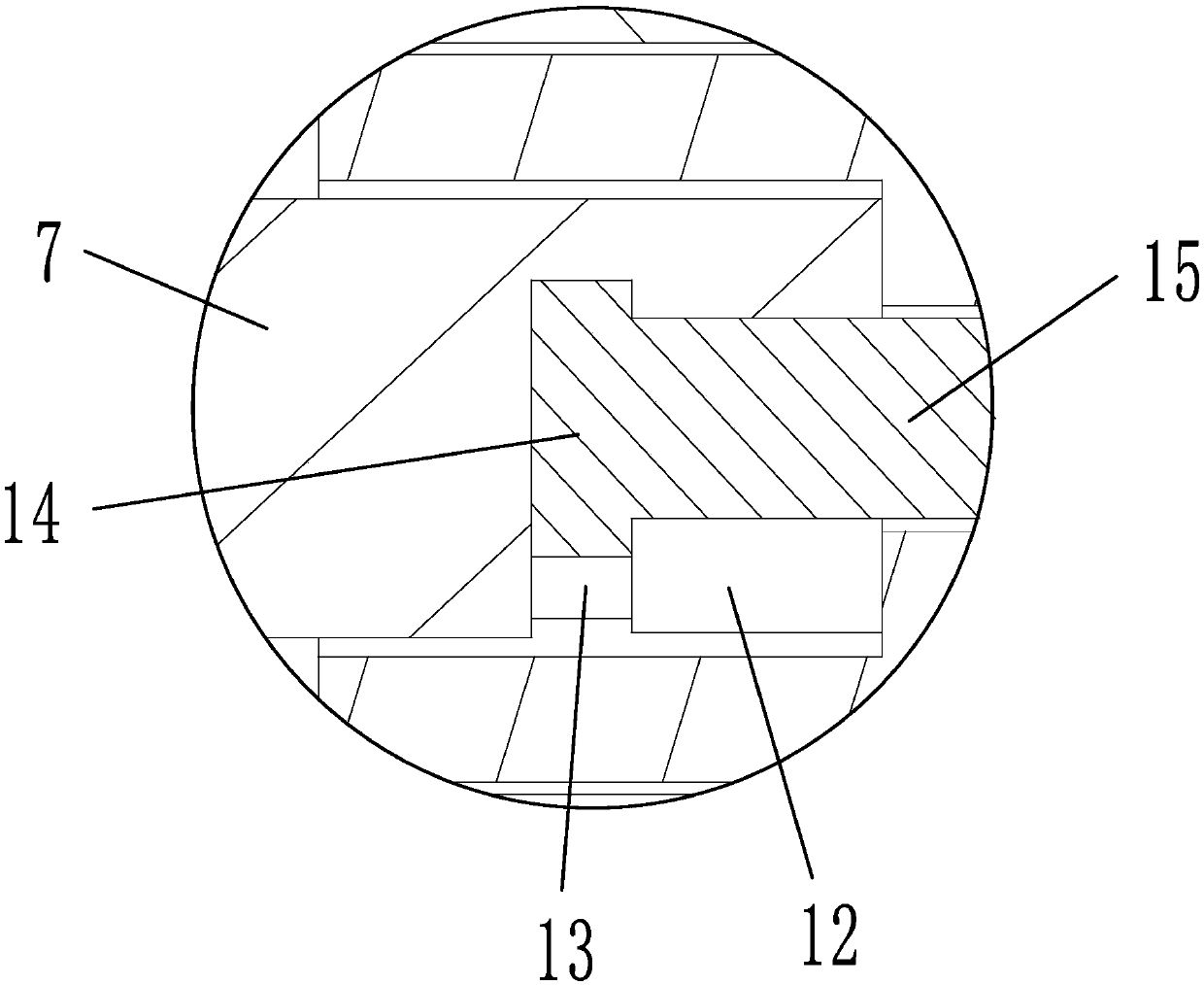

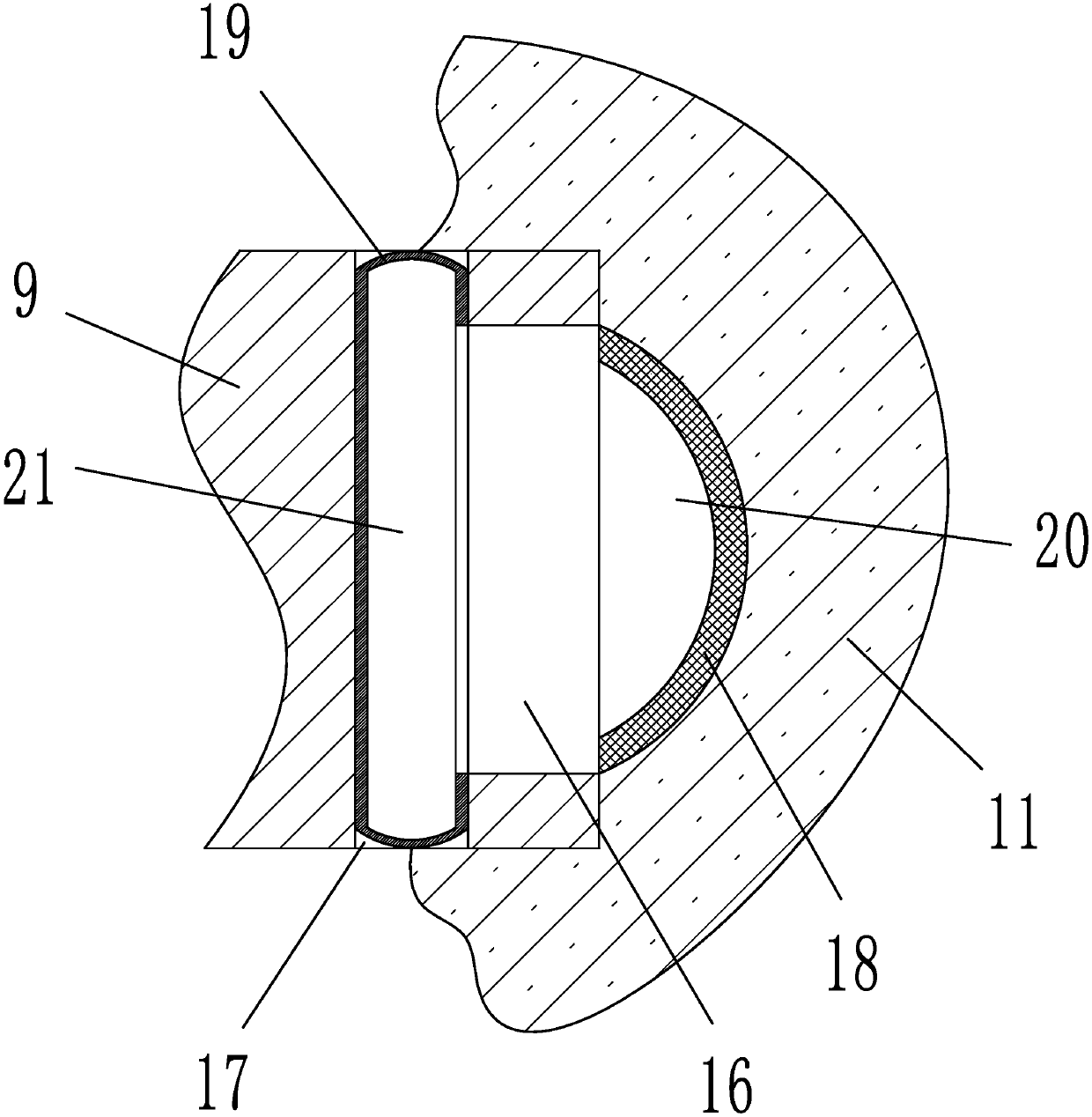

[0015] Embodiment 1: as figure 1 , 2 As shown, a compensation structure for die-casting aluminum includes a movable mold 2 and a fixed mold 1, a product cavity 3 is arranged between the movable mold and the fixed mold, and a movable mold frame 4 is arranged at the end of the movable mold far away from the fixed mold. The end of the mold frame away from the movable mold is provided with a positioning cavity 5, and an extrusion cylinder 6 is arranged in the positioning cavity, and an extrusion connector 7 is arranged on the extrusion cylinder, and the extrusion connector is threadedly connected with the extrusion cylinder, and the extrusion connector An extrusion core 9 is connected to the top, and the outer side of the extrusion joint is provided with a joint support column 8, and the outer side of the extrusion core is provided with an extrusion positioning sleeve 10, and the movable mold is provided with a joint support column and an extrusion The positioning sleeve is match...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com