Preparation method of graphene

A technology of graphene and graphite, which is applied in the field of graphene preparation, can solve the problems of long cycle, complex production process, high production cost, etc., and achieve the effect of short production cycle, simple processing technology and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In the present embodiment, the preparation method of graphene is completed according to the following steps:

[0034] Heat graphite powder with an average particle size of 50 microns in a closed container to a temperature of about 600°C and a pressure of 300kPa, maintain this pressure for 10 minutes, and then quickly depressurize to atmospheric pressure. The above operation was repeated four more times, and the obtained product was ground and dispersed in a 1:4 mixed solution of phenol and ethanol by weight to obtain multilayer graphene.

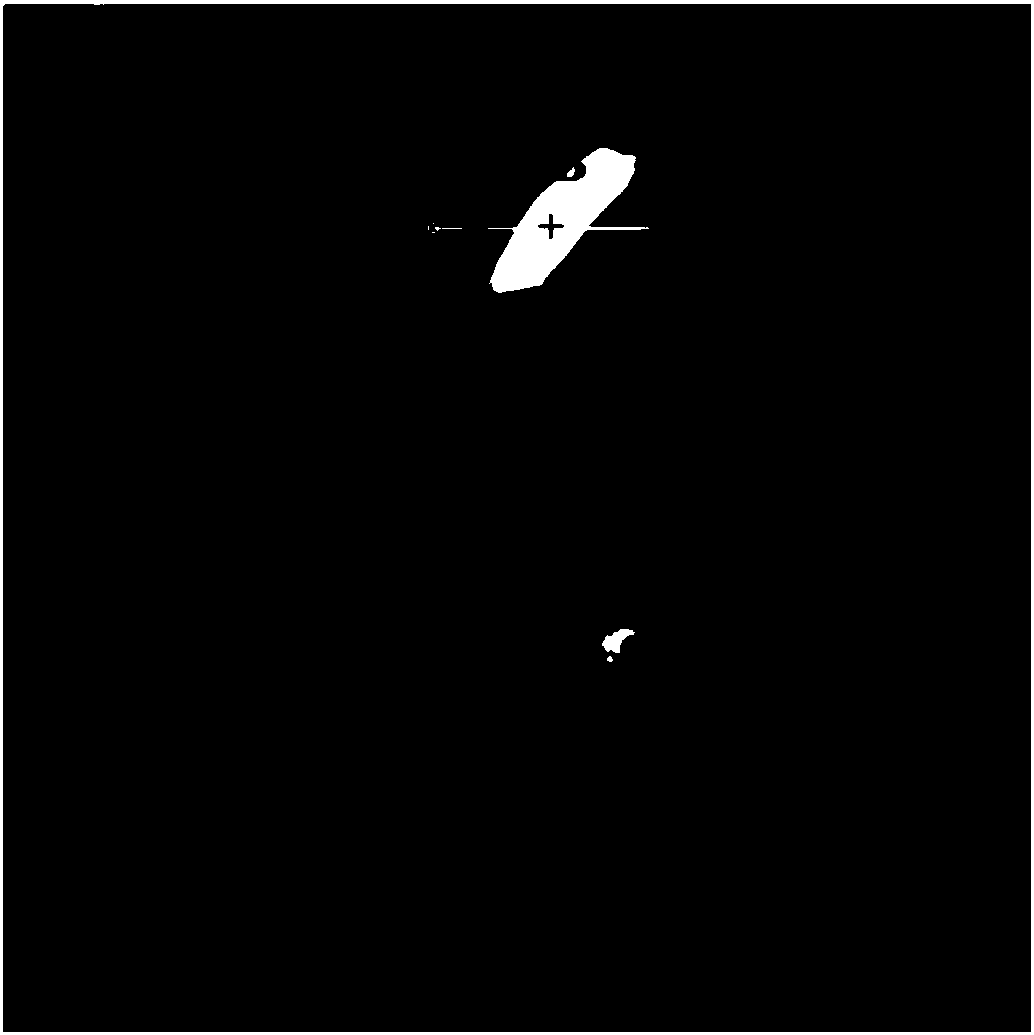

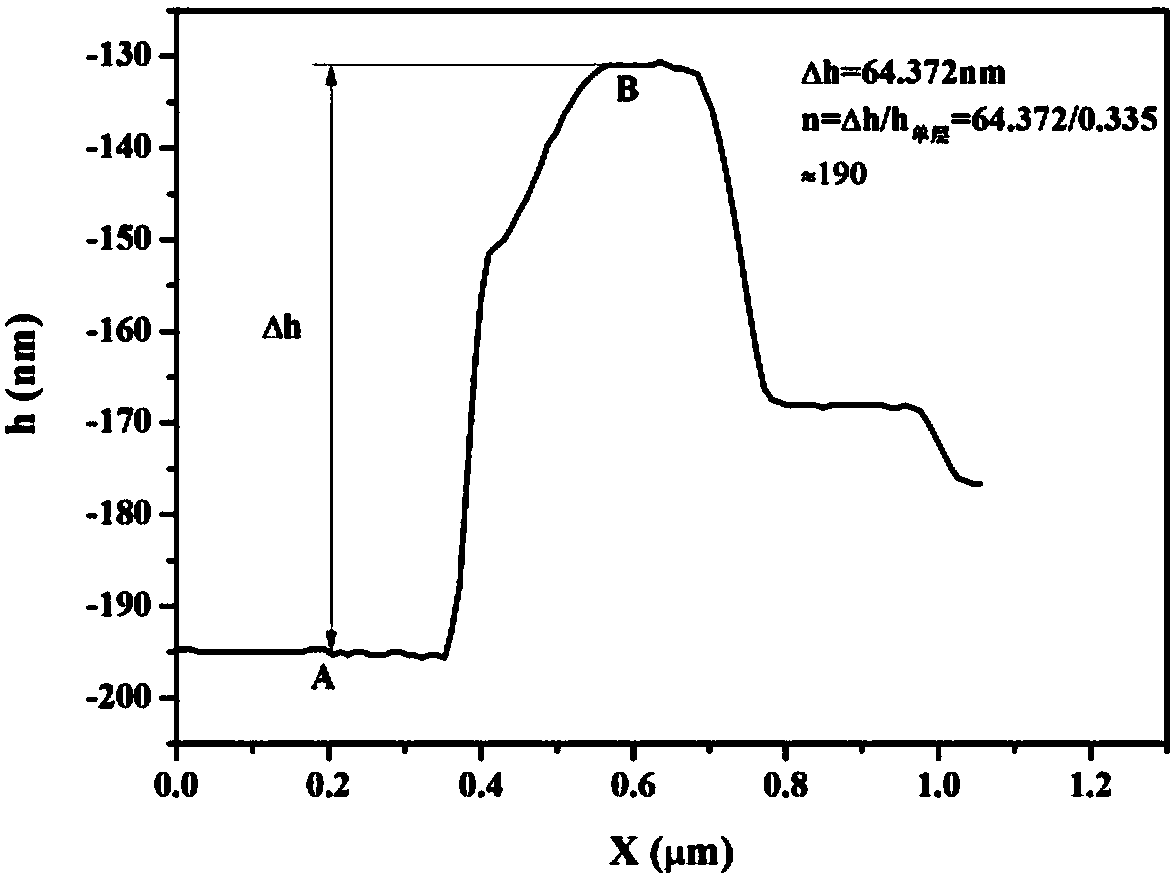

[0035] attached by figure 1 and figure 2 It can be obtained from the analysis that the graphene prepared in this embodiment has a thickness of 64 nanometers and a layer number of about 190 layers. The graphene thickness that present embodiment prepares utilizes atomic force microscope (AFM) to measure, appendix figure 1 For the prepared graphene AFM photo of the present embodiment, appended figure 2 The calculation diagram of th...

Embodiment 2

[0037] In the present embodiment, the preparation method of graphene is completed according to the following steps:

[0038] The 190-layer graphene prepared in Example 1 was pressurized to 500kPa, maintained at this pressure for 7 minutes, quickly decompressed to atmospheric pressure, and repeated the above operation three times. Grind and disperse in the mixed solution to obtain thinner graphene.

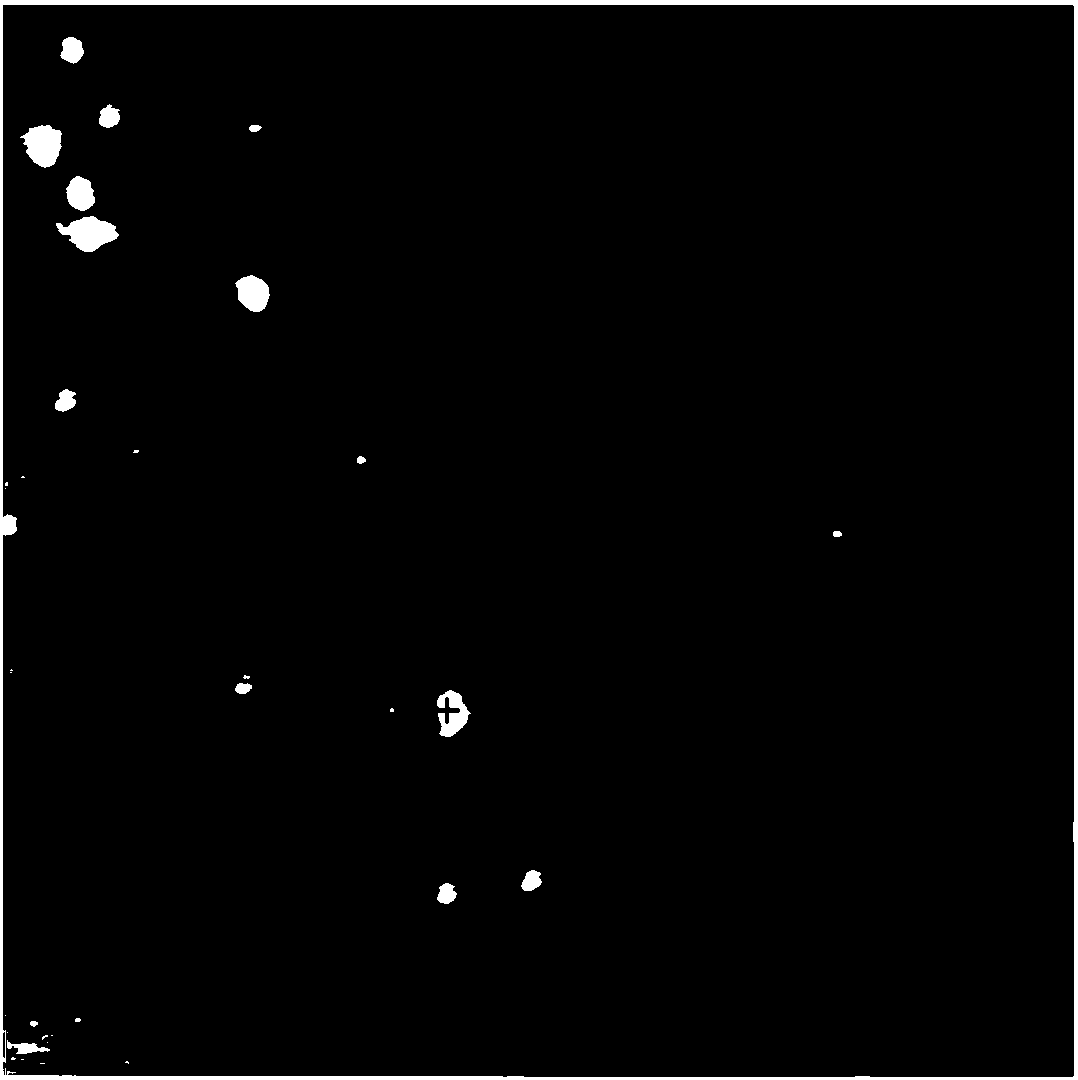

[0039] attached by image 3 and Figure 4 It can be obtained from the analysis that the graphene prepared in this embodiment has a thickness of 18 nanometers and about 50 layers.

Embodiment 3

[0041] In the present embodiment, the preparation method of graphene is completed according to the following steps:

[0042] Pressurize the 50 layers of graphene prepared in Example 2 to 700kPa, maintain this pressure for 5 minutes, quickly depressurize to atmospheric pressure, repeat the above operation twice, and the resulting product is mixed with toluene, ethanol and ether according to the weight ratio of 1:8 :1 in the mixed solution to grind and disperse to obtain thinner graphene.

[0043] attached by Figure 5 and Figure 6 It can be obtained from the analysis that the graphene prepared in this embodiment has a thickness of 6.5 nanometers and about 20 layers.

[0044] The results of the examples show that the single-machine production efficiency of graphene prepared by the present invention reaches 10Kg / h, and the production cost can be reduced to 300,000 yuan / t.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap