A kind of silicon carbide composite ceramics

A technology of multiphase ceramics and silicon carbide, applied in the field of composite materials, can solve the problems of low comprehensive mechanical properties of ceramics, reduced strength, uneven composition of reaction sintered silicon carbide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

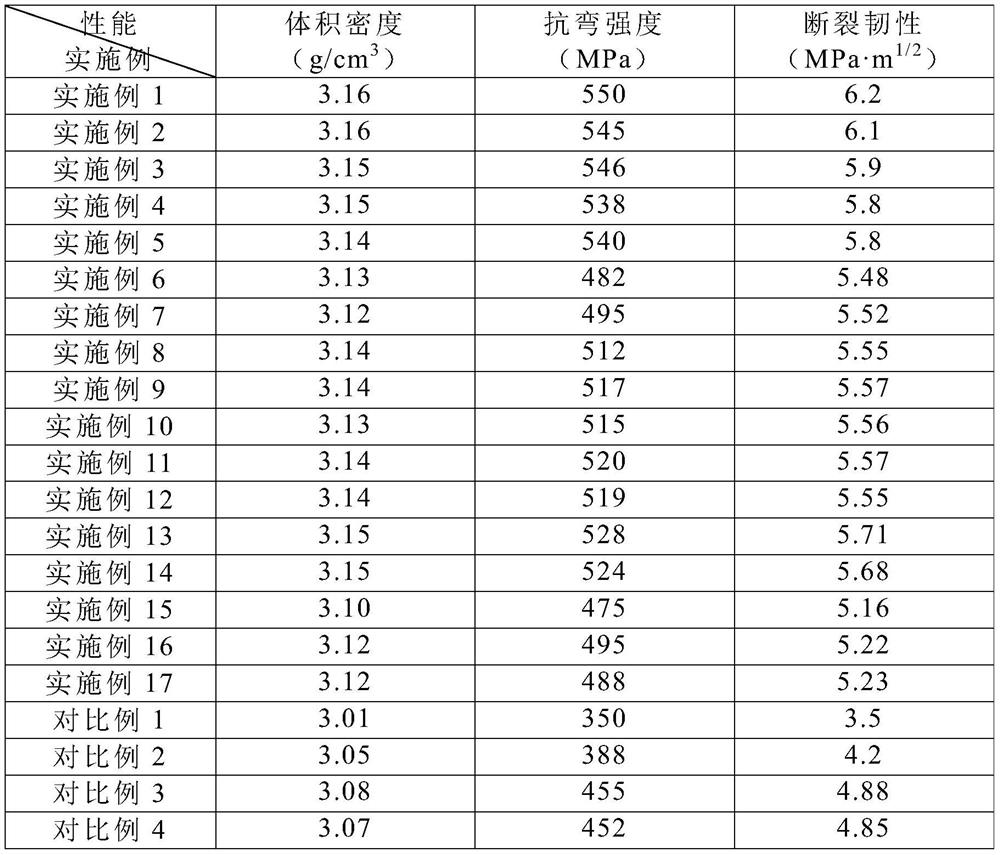

Examples

Embodiment 1

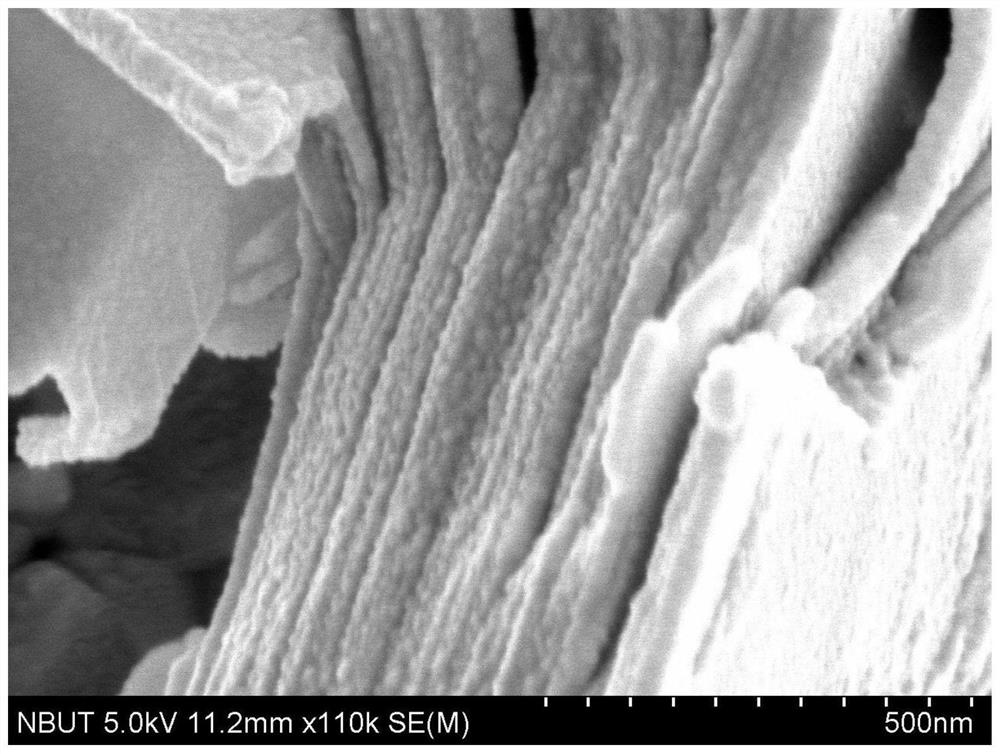

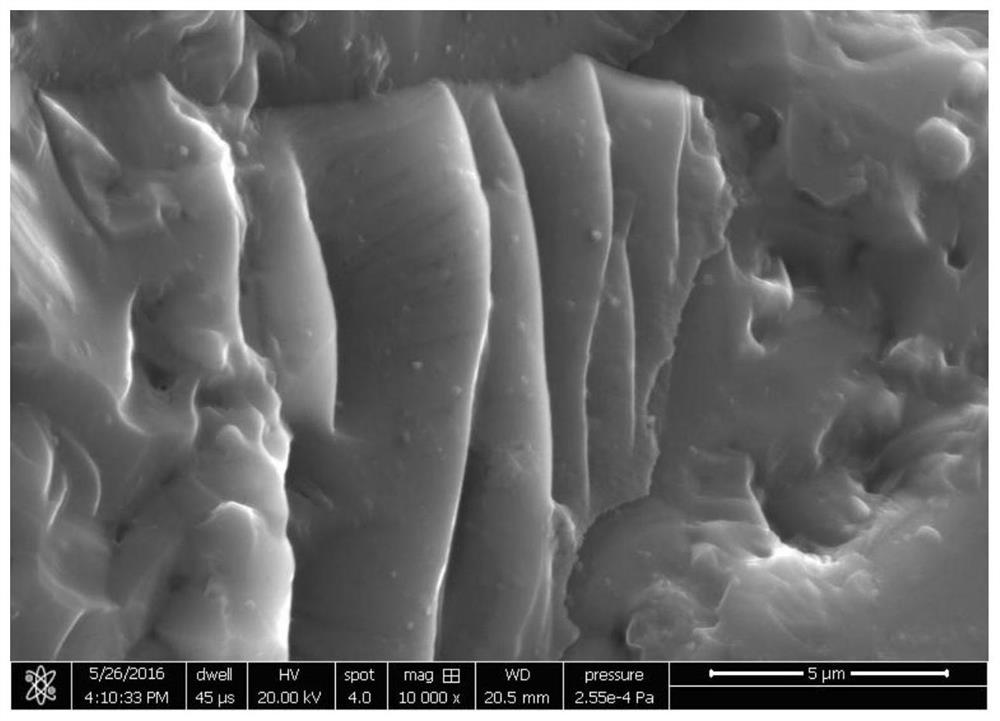

[0044] 1) Accurately weigh 100g of coarse silicon carbide powder I, 250g of fine silicon carbide powder II, 5g of graphene nanosheets, 88g of charcoal black, 14g of tetramethylammonium hydroxide and 21g of sodium carboxymethylcellulose; The particle size is 20-30μm, the particle size of silicon carbide fine powder II is 3-8μm; the thickness of graphene nanosheet is 50-300nm, and the specific surface area of charcoal black is 10-18m 3 / g;

[0045] 2) Add silicon carbide coarse powder I, silicon carbide fine powder II and sodium carboxymethyl cellulose into the dispersion medium ethanol-deionized water, put them into a planetary ball mill for high-speed ball milling for 6 hours, and obtain a slurry; then pre-dispersed graphite Add ene nanosheets, charcoal black and tetramethylammonium hydroxide to the slurry, and continue high-speed ball milling for 12 hours to obtain a ceramic slurry; wherein, the medium for ball milling is high-hardness silicon carbide balls; the viscosity o...

Embodiment 2

[0051] 1) Accurately weigh 100g of silicon carbide coarse powder I, 220g of silicon carbide fine powder II, 6g of graphene nanosheets, 90g of charcoal black, 13g of polyacrylic acid and 22g of epoxy resin; the particle size of silicon carbide coarse powder I is 20-30μm, The particle size of silicon carbide fine powder II is 3-8μm; the thickness of graphene nanosheets is 50-300nm, and the specific surface area of charcoal black is 10-18m 3 / g;

[0052] 2) Add silicon carbide coarse powder I, silicon carbide fine powder II and epoxy resin into the dispersion medium ethanol-deionized water, put them into a planetary ball mill for high-speed ball milling for 6 hours to obtain a slurry; then pre-dispersed graphene nanosheets 1. Charcoal black and polyacrylic acid are added to the slurry, and the high-speed ball milling is continued for 12 hours to obtain a ceramic slurry; wherein, the medium of the ball milling is a high-hardness silicon carbide ball;

[0053] 3) Inject the unif...

Embodiment 3

[0057] 1) Accurately weigh 100g of silicon carbide coarse powder I, 280g of silicon carbide fine powder II, 4.5g of graphene nanosheets, 84g of charcoal black, 13g of tetramethylammonium hydroxide and 25g of organic silicon; the particle size of silicon carbide coarse powder I is 20-30μm, the particle size of silicon carbide fine powder II is 3-8μm; the thickness of graphene nanosheets is 50-300nm, and the specific surface area of charcoal black is 10-18m 3 / g;

[0058] 2) Add silicon carbide coarse powder I, silicon carbide fine powder II and organic silicon into the dispersion medium ethanol, put them into a planetary ball mill for high-speed ball milling for 5 hours, and obtain a slurry; then pre-dispersed graphene nanosheets, charcoal black Add tetramethylammonium hydroxide to the slurry, and continue high-speed ball milling for 10 hours to obtain a ceramic slurry; wherein, the medium for ball milling is high-hardness silicon carbide balls;

[0059] 3) Inject the unifor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com