A wellbore dynamic liquid level monitoring method for drilling and plugging construction

A technology of wellbore and liquid level, which is applied in wellbore/well components, measurement, earth-moving drilling and production, etc., can solve the problems of difficult to truly reflect the plugging slurry and the low success rate of plugging, so as to improve the success rate of plugging and improve the The effect of knowledge and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

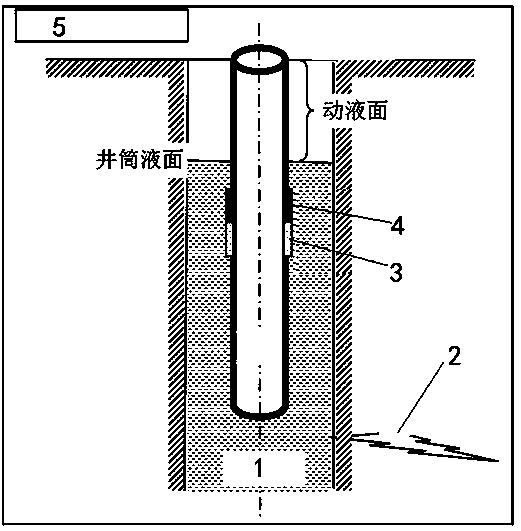

[0021] As a preferred embodiment of the present invention, with reference to the attached figure 1 , this example discloses:

[0022] A wellbore liquid level monitoring method for drilling leak plugging construction, comprising the following steps:

[0023] Step A: Estimate the static liquid level position of the wellbore 1 after the plugging operation is completed according to the pressure of the leaking layer 2 and the selected plugging construction plan;

[0024] Step B: Connect the pressure testing instrument with the plugging drilling tool assembly, and put the connected pressure testing instrument into the wellbore 1, so that the position of the pressure testing instrument in the wellbore 1 is located at the hydrostatic fluid estimated in step A below the face;

[0025] Step C: start the plugging operation, start the pressure testing instrument, and monitor the dynamic liquid level of the wellbore 1 in real time;

[0026] Step D: Calculate the position of the plugging...

Embodiment 2

[0028] As another preferred embodiment of the present invention, with reference to the attached figure 1 , this example discloses:

[0029] A wellbore liquid level monitoring method for drilling leak plugging construction, comprising the following steps:

[0030] Step A: Estimate the static liquid level position of the wellbore 1 after the plugging operation is completed according to the pressure of the leaking layer 2 and the selected plugging construction plan;

[0031] Step B: Connect the pressure testing instrument with the plugging drilling tool assembly, and put the connected pressure testing instrument into the wellbore 1, so that the position of the pressure testing instrument in the wellbore 1 is located at the hydrostatic fluid estimated in step A below the face;

[0032] Step C: start the plugging operation, start the pressure testing instrument, and monitor the dynamic liquid level of the wellbore 1 in real time;

[0033] Step D: Calculate the position of the pl...

Embodiment 3

[0037] As another preferred embodiment of the present invention, with reference to the attached figure 1 , this example discloses:

[0038] A wellbore 1 fluid level monitoring method for drilling plugging construction, comprising the following steps:

[0039] Step A. Estimate the static liquid level position of the wellbore 1 after the plugging construction operation is completed according to the pressure of the leaking layer 2 and the selected plugging construction plan;

[0040] Step B: Connect the pressure testing instrument with the plugging drilling tool assembly, and put the connected pressure testing instrument into the wellbore 1, so that the position of the pressure testing instrument in the wellbore 1 is located at the hydrostatic fluid estimated in step A below the face;

[0041] Step C: start the plugging operation, start the pressure testing instrument, and monitor the dynamic liquid level of the wellbore 1 in real time;

[0042] Step D: Calculate the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com