A Fixing Method for Fluorescent Temperature Measuring Sensor Inside Transformer

A temperature measurement sensor and transformer technology, applied in the field of power transformers, can solve the problems of damage, easy to be broken, torn off, complex structure, etc. of the fluorescent temperature measurement sensor, and achieve the effects of reliable fixation, overcoming easy damage, and improving the success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

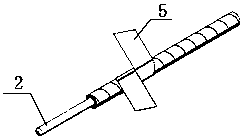

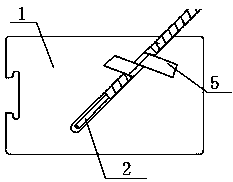

[0029] Embodiment one, with reference to the attached figure 1 , 2 , 5.

[0030] For the fluorescent temperature measuring sensor without a buckle, make an insulating paper tape 5; apply adhesive 10mm from the end of the fluorescent temperature measuring sensor, wrap the fluorescent temperature measuring sensor 2 with insulating paper tape 5, and do not cover the fluorescent temperature measuring sensor. The end of the temperature sensor; then paste the excess part of the insulating paper tape on the insulating standard part 1, and finally paste a 1mm thick insulating cardboard 4 on the top and bottom of the standard insulating part. The shape of the insulating cardboard is the same as that of the standard insulating part Consistent, and press the two layers of insulating cardboard together with the standard insulating part; form the insulating cardboard with the fluorescent temperature sensor and the standard insulating part combination 7.

Embodiment 2

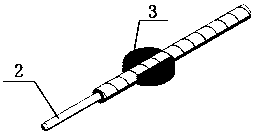

[0031] Embodiment two, referring to the attached image 3 , 4 , 5.

[0032] For the fluorescent temperature measuring sensor with its own buckle, make a slot 3 that matches the buckle; fix the buckle of the fluorescent temperature sensor 2 in the slot 3, and fix the slot on the standard insulator 1. A 1mm thick insulating cardboard 4 is pasted on the top and bottom of the standard insulating part respectively. The shape of the insulating cardboard is consistent with that of the standard insulating part, and the two layers of insulating cardboard are pressed together with the standard insulating part; Combination of insulating cardboard and standard insulating parts7.

[0033] Place the insulating cardboard with the fluorescent temperature sensor and the standard insulator combination 7 in the transformer winding to complete the fixation of the fluorescent temperature sensor inside the transformer.

Embodiment 3

[0034] Embodiment three, with reference to the attached Figure 6 , 7 .

[0035] This standard insulation is the same shape and size as the original insulation standard used in the transformer windings.

[0036] For pie-type windings and spiral windings, the installation of the fluorescent temperature sensor is completed after the winding is completed and before the winding is compacted and shaped; the insulating cardboard with the fluorescent temperature sensor and the standard insulator assembly 7 are placed on the winding wire cake 6, replace the insulation standard parts in the original position between the winding wire cakes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com