Three-degree-of-freedom spherical rotor ultrasonic motor stator base and excitation method thereof

A technology of spherical rotor and ultrasonic motor, which is applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc. It can solve the problems of less driving feet, difficult miniaturization, complex structure, etc. , to achieve the effects of simple structure, easy miniaturization, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

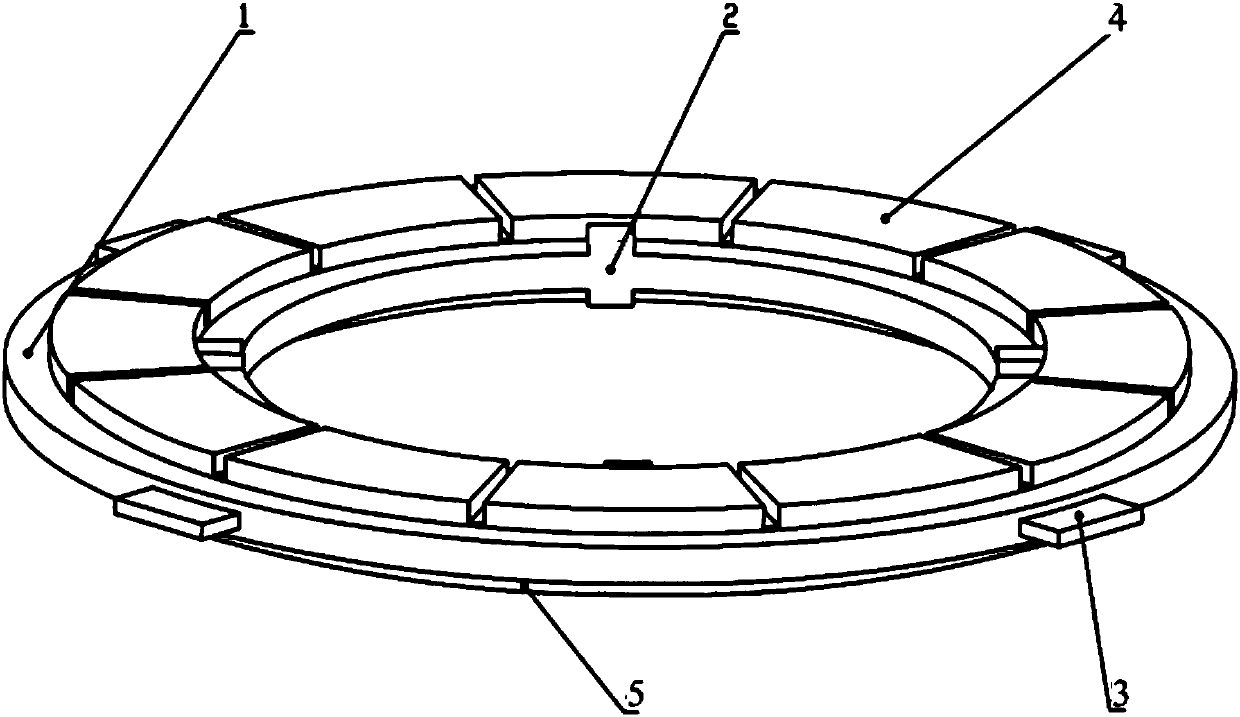

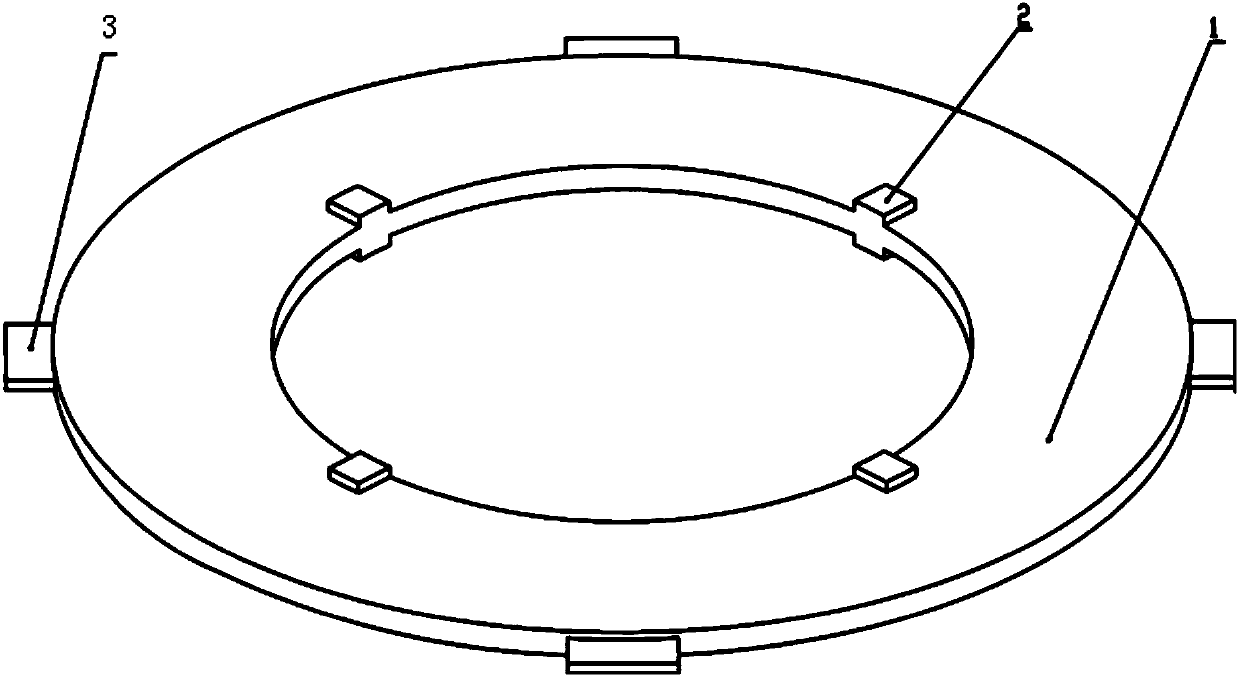

[0036] Specific implementation mode one: refer to Figure 1 to Figure 4 Describe this embodiment in detail. The stator base of the three-degree-of-freedom spherical rotor ultrasonic motor described in this embodiment includes a metal ring 1, four driving feet 2, ear-shaped fixed ends 3, an upper piezoelectric ceramic ring 4 and a lower piezoelectric ceramic ring. ceramic ring 5,

[0037] The four driving feet 2 are evenly embedded in the inner ring of the metal ring 1, and the four ear-shaped fixed ends 3 are evenly arranged on the outer ring of the metal ring 1.

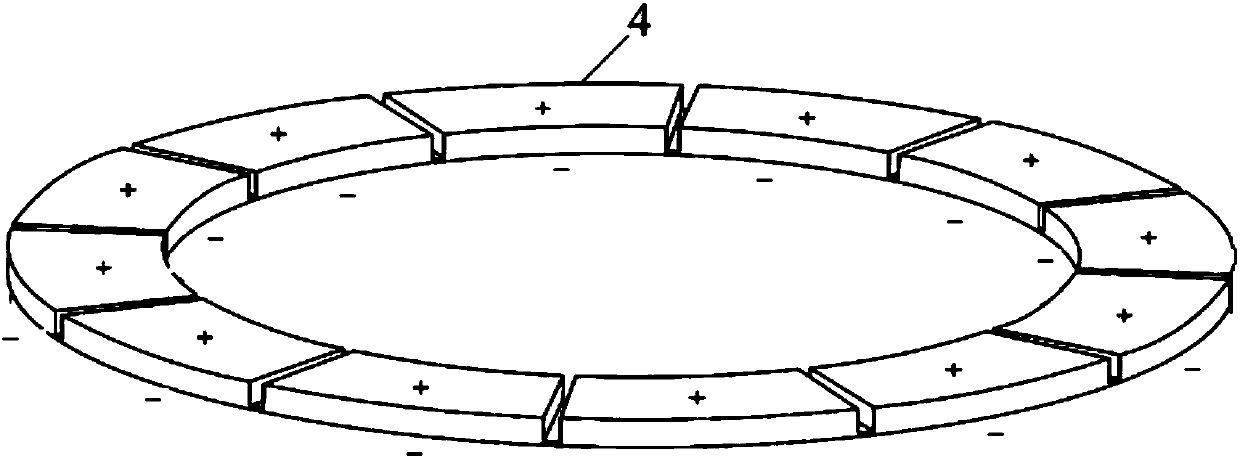

[0038] The upper piezoelectric ceramic ring 4 is located on the upper surface of the metal ring 1. The upper piezoelectric ceramic ring 4 is equally divided into twelve upper piezoelectric ceramic partitions, and there is a gap between two adjacent piezoelectric ceramic partitions. A silver-plated layer is provided, and the twelve upper-layer piezoelectric ceramic partitions are all polarized along the thickness di...

specific Embodiment approach 2

[0044]Embodiment 2: This embodiment is to further explain the stator base of the three-degree-of-freedom spherical rotor ultrasonic motor described in Embodiment 1. In this embodiment, each upper piezoelectric ceramic partition and the corresponding lower piezoelectric ceramic partition The spatial phase difference of 15°.

specific Embodiment approach 3

[0045] Embodiment 3: This embodiment is to further explain the three-degree-of-freedom spherical rotor ultrasonic motor stator base described in Embodiment 1. In this embodiment, the straight line formed from the ear-shaped fixed end 3 to the center of the circle and the adjacent drive The included angle between the straight line formed by foot 2 and the center of the circle is 45°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com