High speed blender for five cereals

A cooking machine and grain technology, applied in the field of household food processing equipment, can solve the problems of high technical requirements, high price, low wall breaking rate, etc., and achieve the effects of improving wall breaking efficiency, reducing use time and increasing contact probability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

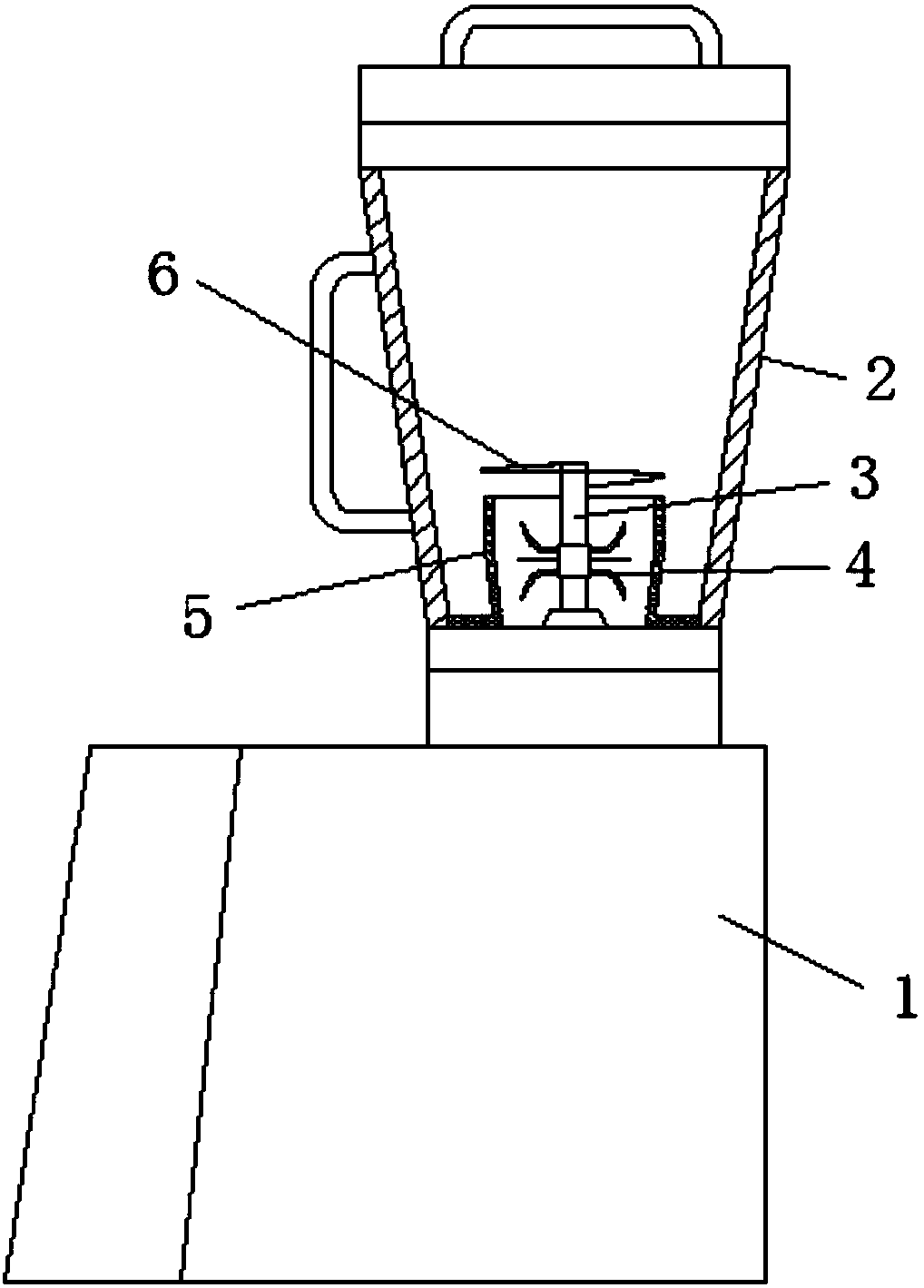

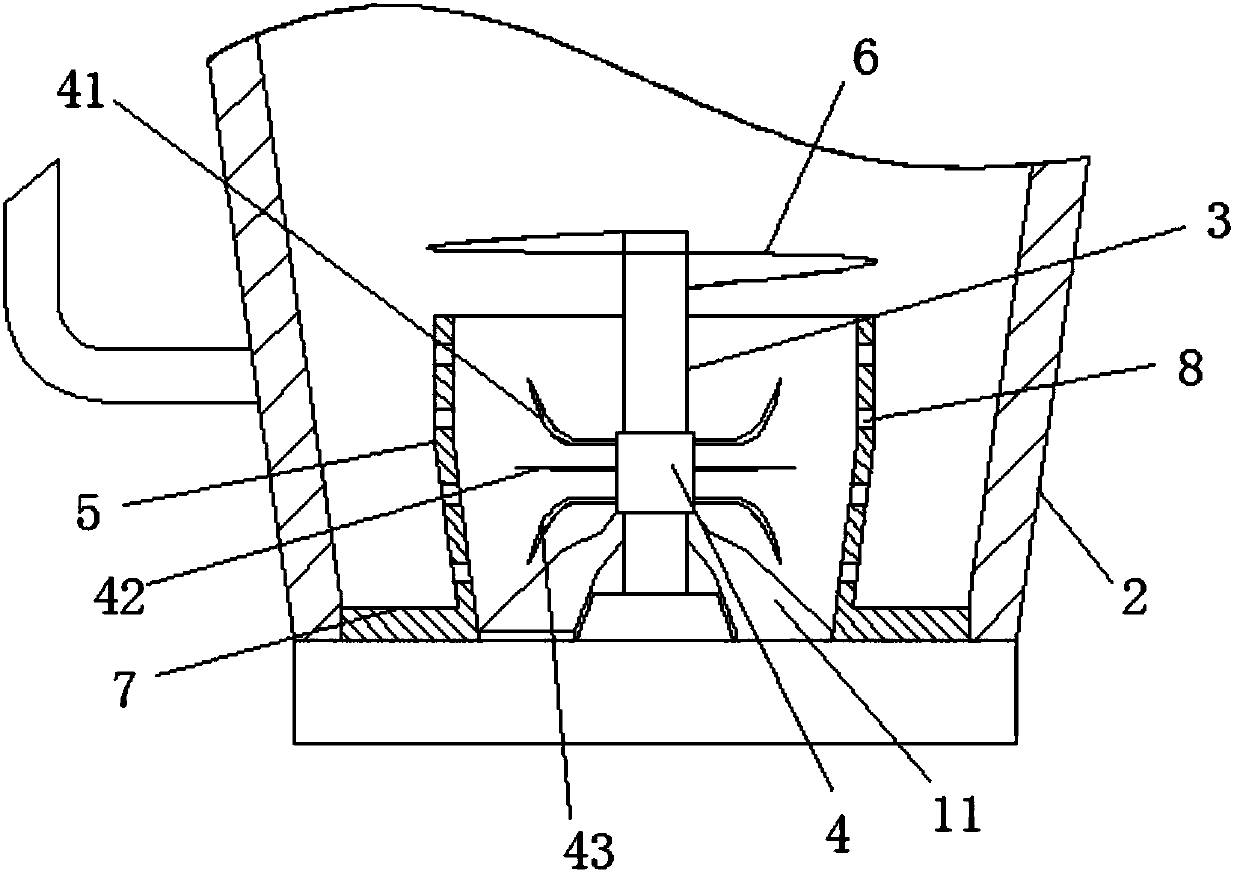

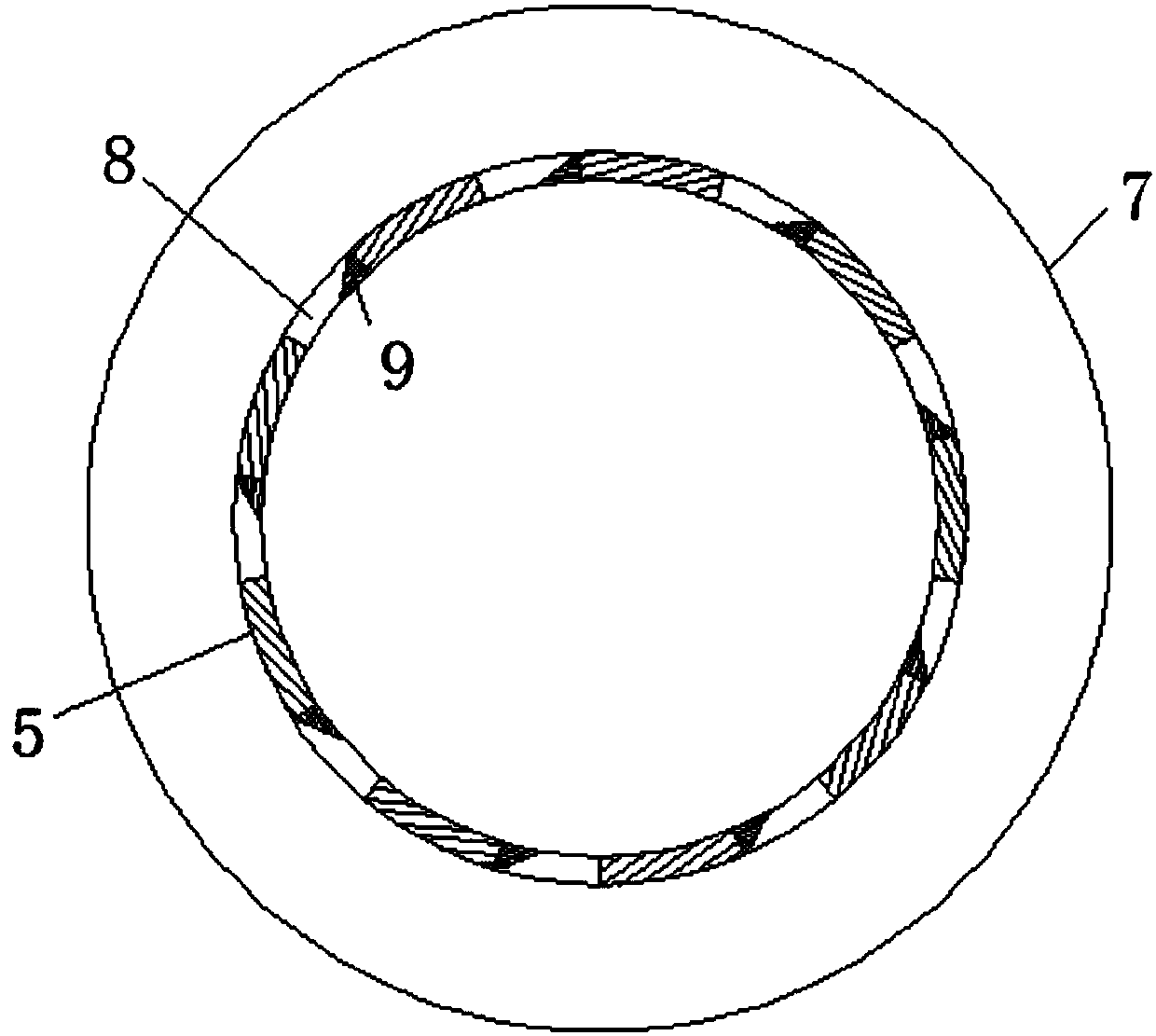

[0017] Such as Figure 1-4 As shown, a five-grain wall-breaking cooking machine includes a machine base 1 and a cup body 2 installed on the machine base 1. A rotating shaft 3 is arranged at the center of the inner bottom surface of the cup body 2, and a blade set 4 is fixedly arranged at the middle and lower part of the rotating shaft 3. , the blade set 4 includes an upper cutter 41, a flat cutter 42 and a lower cutter 43, and is installed in an upper, middle and lower arrangement, and the angle of inclination between the upper cutter 41 and the lower cutter 43 is 60°--90°. The angle range can effectively improve the wall-breaking efficiency of the cutter. The cutting edge of the blade set 4 is provided with serrations 10, which increase the contact length with the cell wall and improve the wall-breaking efficiency. The upper end of the rotating shaft 3 is fixedly provided with a helical blade 6 , the outside of the rotating shaft 3 is located on the inner bottom surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com