Ultrasonic laser drilling device

An ultrasonic and drilling technology, which is applied in the direction of drilling equipment, earthwork drilling, drilling equipment and methods, etc., can solve the problem of not being able to drill through hard strata and rock formations, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

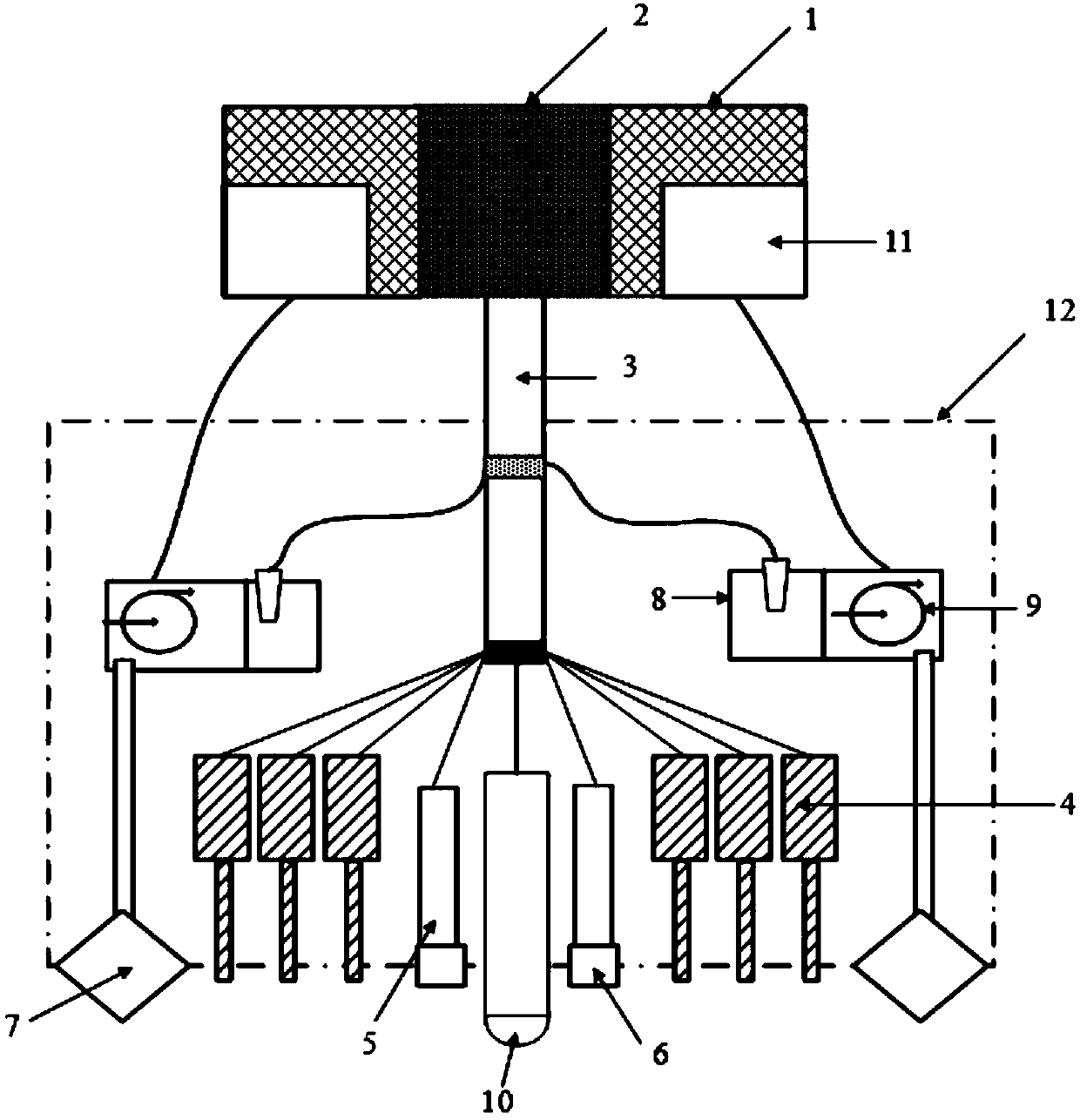

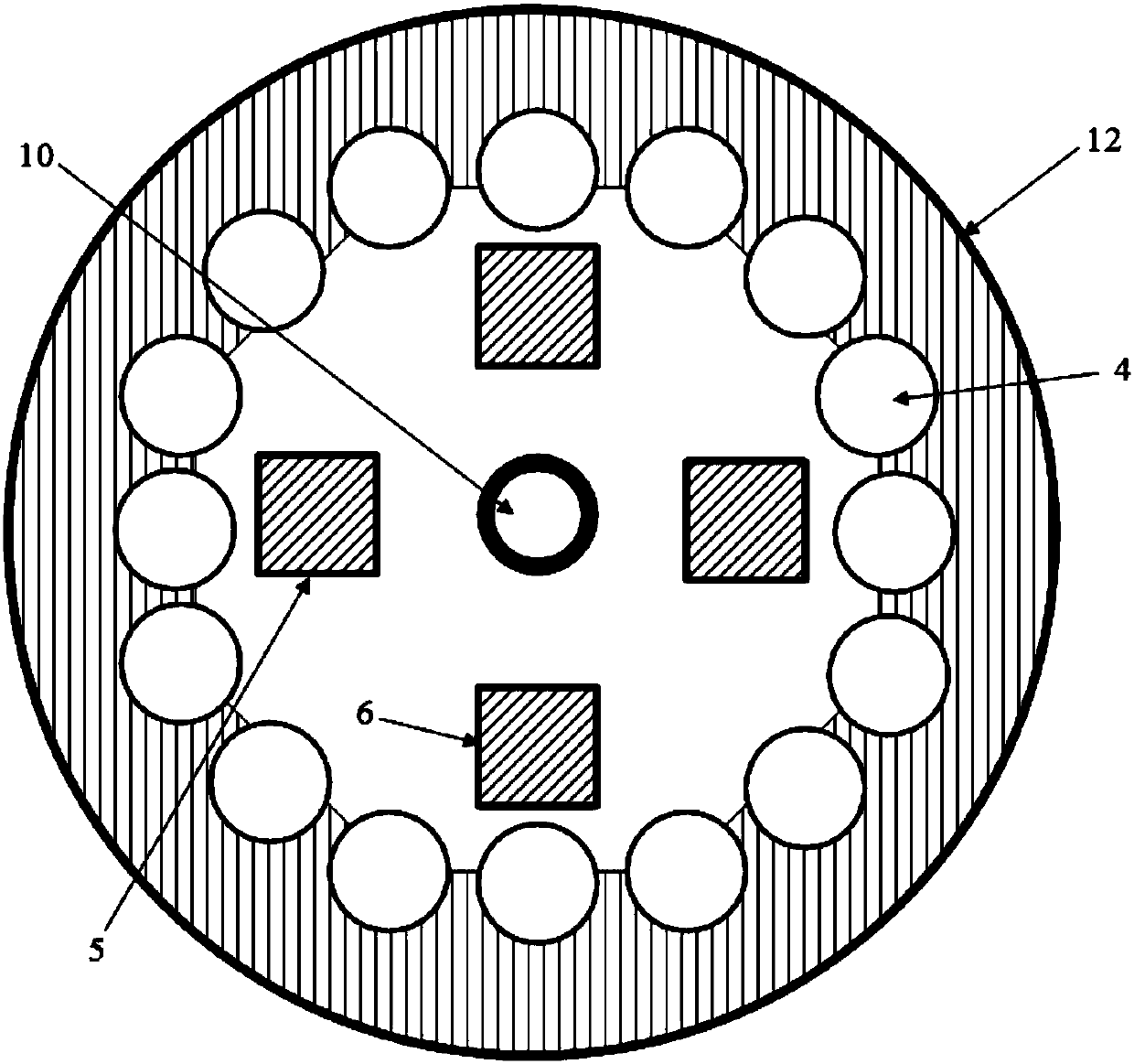

[0016] An ultrasonic laser drilling device is characterized in that it includes: a cooling unit 1, a control unit 2, a connecting pipe 3, a filter tank 11, a high-power pulsed laser array 4, an ultrasonic generator 5 and an ultrasonic focusing array 6, wherein the communicating pipe There are cables, high-strength water pipes and return pipes in the 3, and the cables in the connecting pipe 3 connect the control unit 2 with the high-power pulsed laser array 4, multiple ultrasonic generators 5, ultrasonic focusing array 6 and The air pump 9 is connected, and the high-strength water pipe in the connecting pipe 3 connects the cooling unit 1 with the cooling water circulation system of the high-power pulse laser array 4, the ultrasonic generator 5 and the ultrasonic focusing array 6, and the cooled water passes through the connecting pipe 3. The return water pipe returns to the cooling unit 1, the high-strength water pipe in the communication pipe 3 is also connected to the water st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com