Built-in type building settlement observation nail

A subsidence observation and adduction-type technology, which is applied in the directions of measuring devices, surveying and navigation, height/horizontal measurement, etc., can solve problems such as limited length of measuring nails, influence of data accuracy, and damage of measuring nails, so as to eliminate errors and achieve accurate Data, to avoid artificial damage or deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

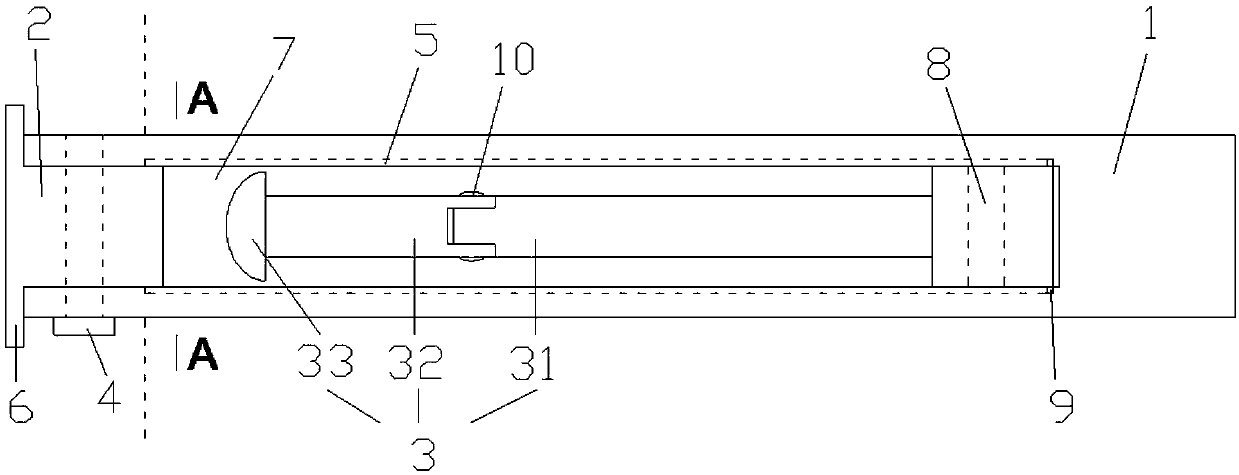

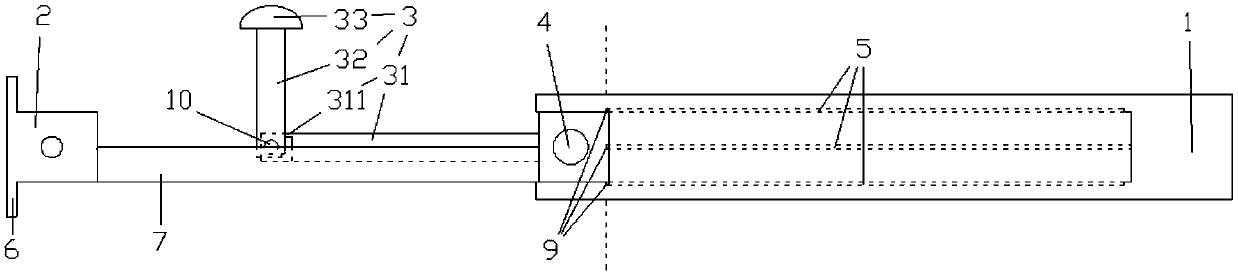

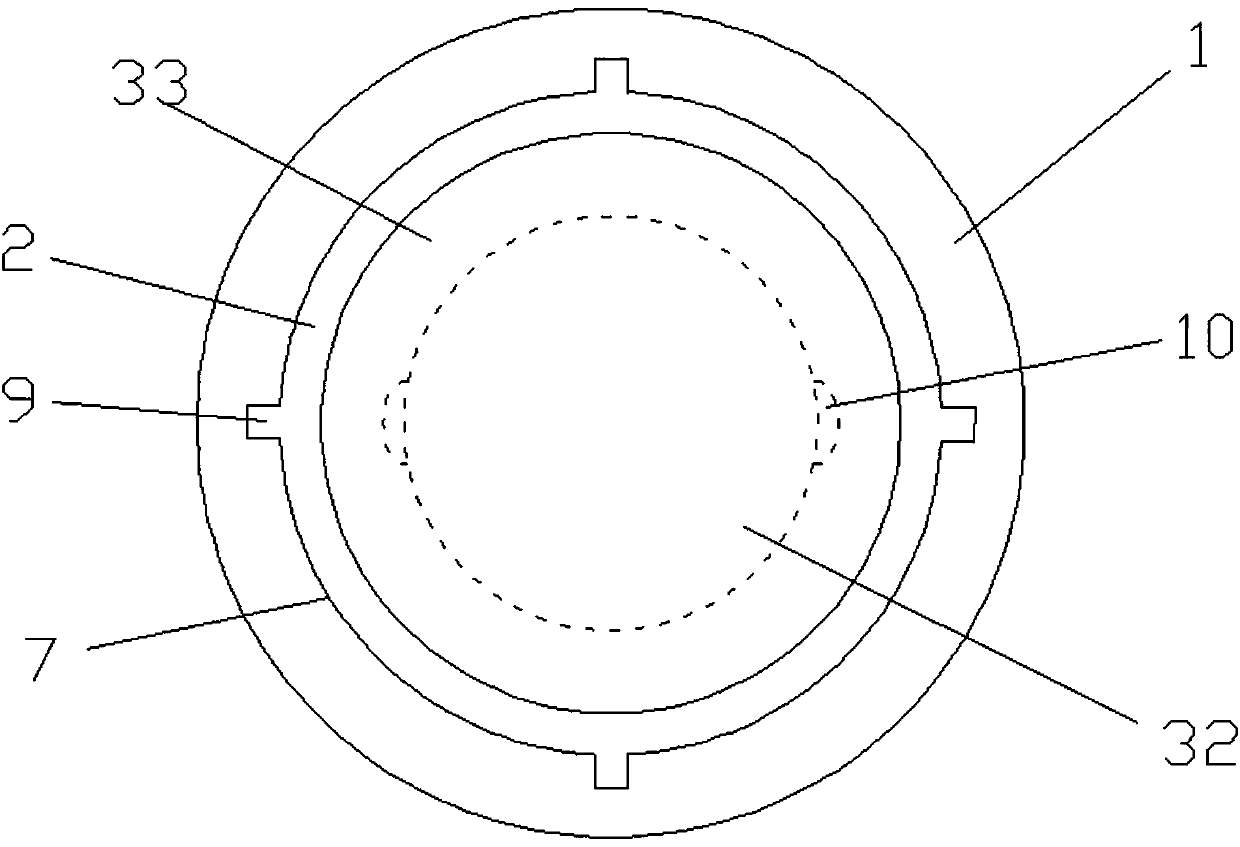

[0015] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] see figure 1 , figure 2 , image 3 As shown, the present invention is a retractable building settlement observation nail, which includes a sleeve 1 and a guide rod 2 that can slide inside it. Slide guide rod 2 is fixed by set screw 4. The outer wall of the sleeve 1 has a scale line 3 cm away from the barrel mouth, which is convenient for determining the embedding depth; the inner wall is coated with a layer of lubricating liquid, which can effectively reduce the friction of the guide rod 2 moving therein. On the inner wall of the sleeve 1, four concave guide grooves 5 are equidistantly distributed, and the guide grooves stop at 3 cm from the opening of the sleeve 1. The bottom of the guide rod 2 is equidistantly distributed with four grooves embedded in the concave guide grooves 5. The fixed block 9 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com