Adjusting type bearing frame for shaft machining

An adjustable and bearing frame technology, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems that cannot be adjusted according to needs, affect the precision of shaft processing, affect applicability and practicability, etc. To achieve the effect of ensuring the stability of placement, reliable top pressure position and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

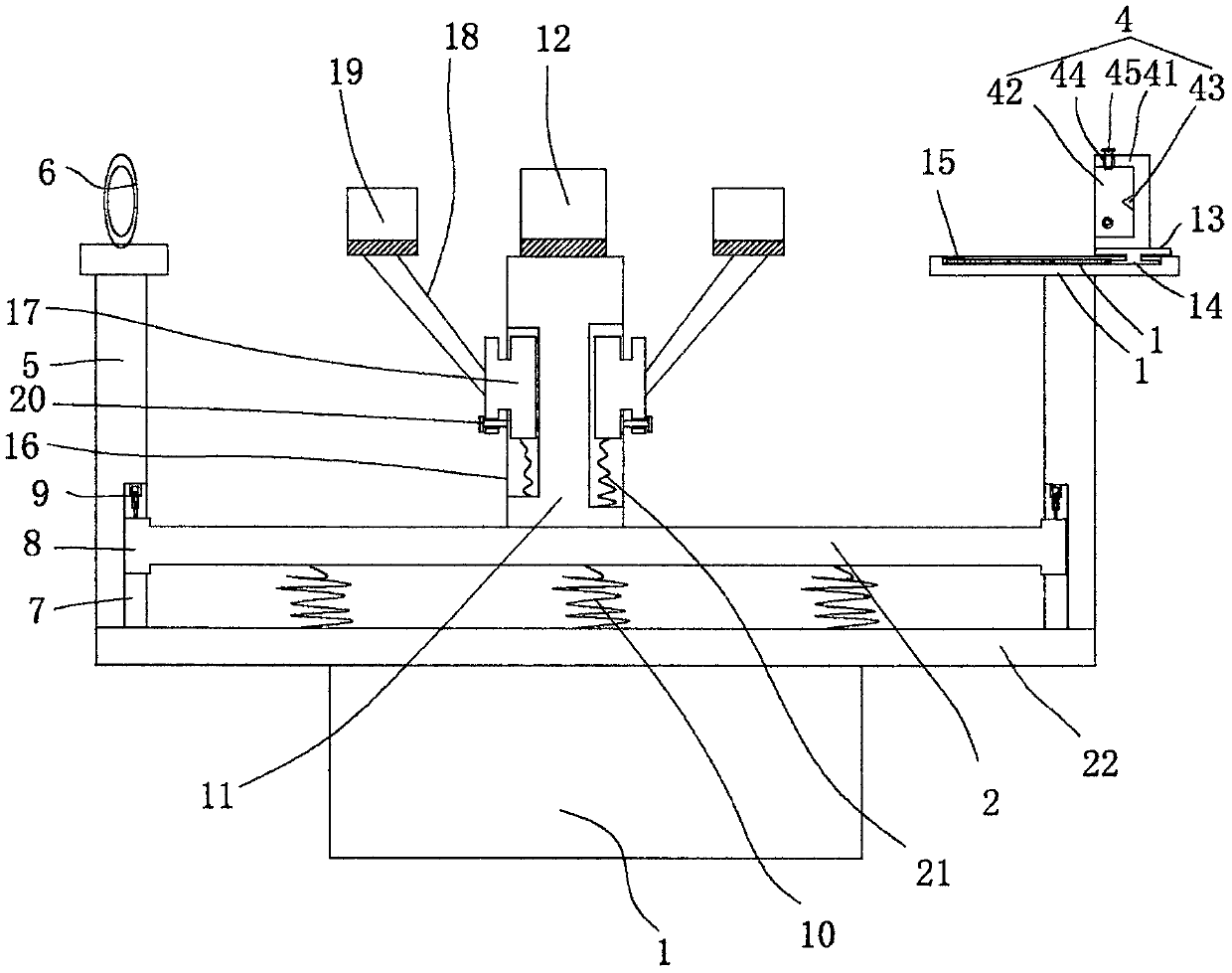

[0014] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0015] See figure 1 , an adjustable bearing frame for shaft processing, including a base frame 1 and a bearing seat 2 arranged on the base frame 1, a reference end clamping seat 3 is provided at one end of the bearing base 2, and the A clamping body 4 is fixed on the reference end clamp seat 3, a pressing seat 5 is provided at the other end of the bearing seat 2, a perforation 6 is arranged on the pressing seat 5 and the top is at the center of the perforation, so The center of the clamping body 4 is on the same straight line as the center of the perforation, and a vertical adjustment chute 7 is fixed on the inner surface of the pressing seat 5 and the reference end clamping seat 3, and on both sides of the bearing seat 2 The end is fixed with an I-shaped slider 8, and the I-shaped slider 8 is in the vertical adjustment chute 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com