Sealing structure for hydraulic motor

A sealing structure, hydraulic motor technology, applied in the direction of engine sealing, fluid pressure actuators, engine components, etc., can solve the problem of increasing the cost of sealing devices, affecting the characteristics of sealing structure materials for hydraulic motors, and increasing the disassembly of sealing structures for hydraulic motors and the difficulty of replacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

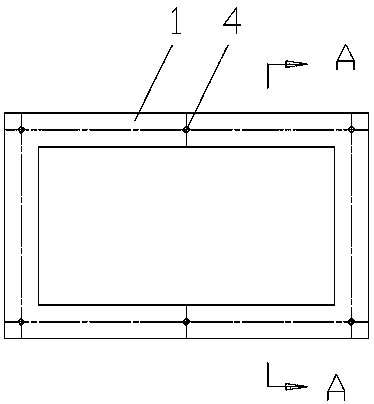

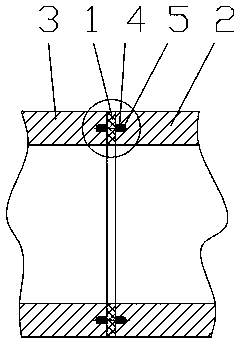

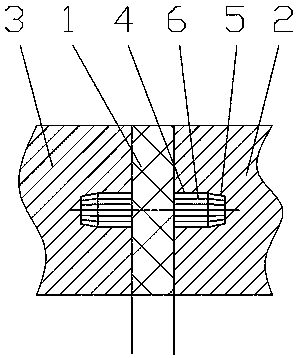

[0019] Such as figure 1 with figure 2 As shown, a sealing structure for a hydraulic motor includes a sealing structure body 1 for a hydraulic motor clamped between the first sealed part 2 and the second sealed part 3 . On one side of the sealing structure body 1 for the hydraulic motor, there are 6 pins 4, of which 4 pins 4 are respectively arranged near the 4 corners of the sealing structure body 1 for the hydraulic motor; It is determined by the rigidity requirements of the sealing structure body 1, but at least two pins 4 are required; in order to increase the positioning effect between the sealed part one 2 and the sealed part two 3, it can also be used on both sides of the hydraulic motor sealing structure body 1 Pin 4 is set on both. Described pin 4 is a square prism, and the circumscribed circle diameter of pin 4 is 3mm, and the length of pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com