Rotating scraping dust removal machine

A technology of dust remover and rotating scraper, which is applied in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, etc., can solve the problems of clogging the filter device, increase the cost of enterprise dust removal, and reduce the service life of the dust removal device, and achieve the separation effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

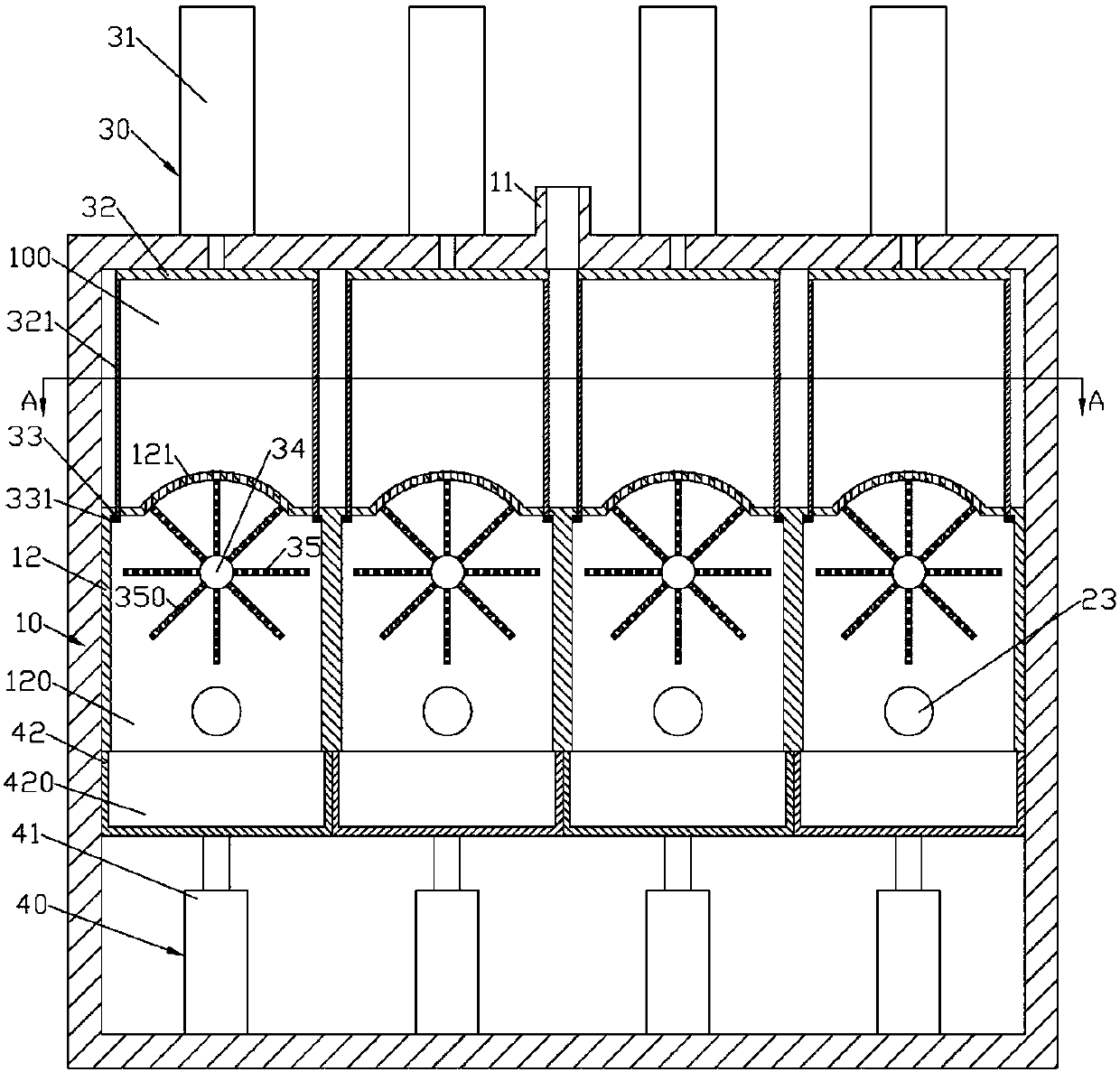

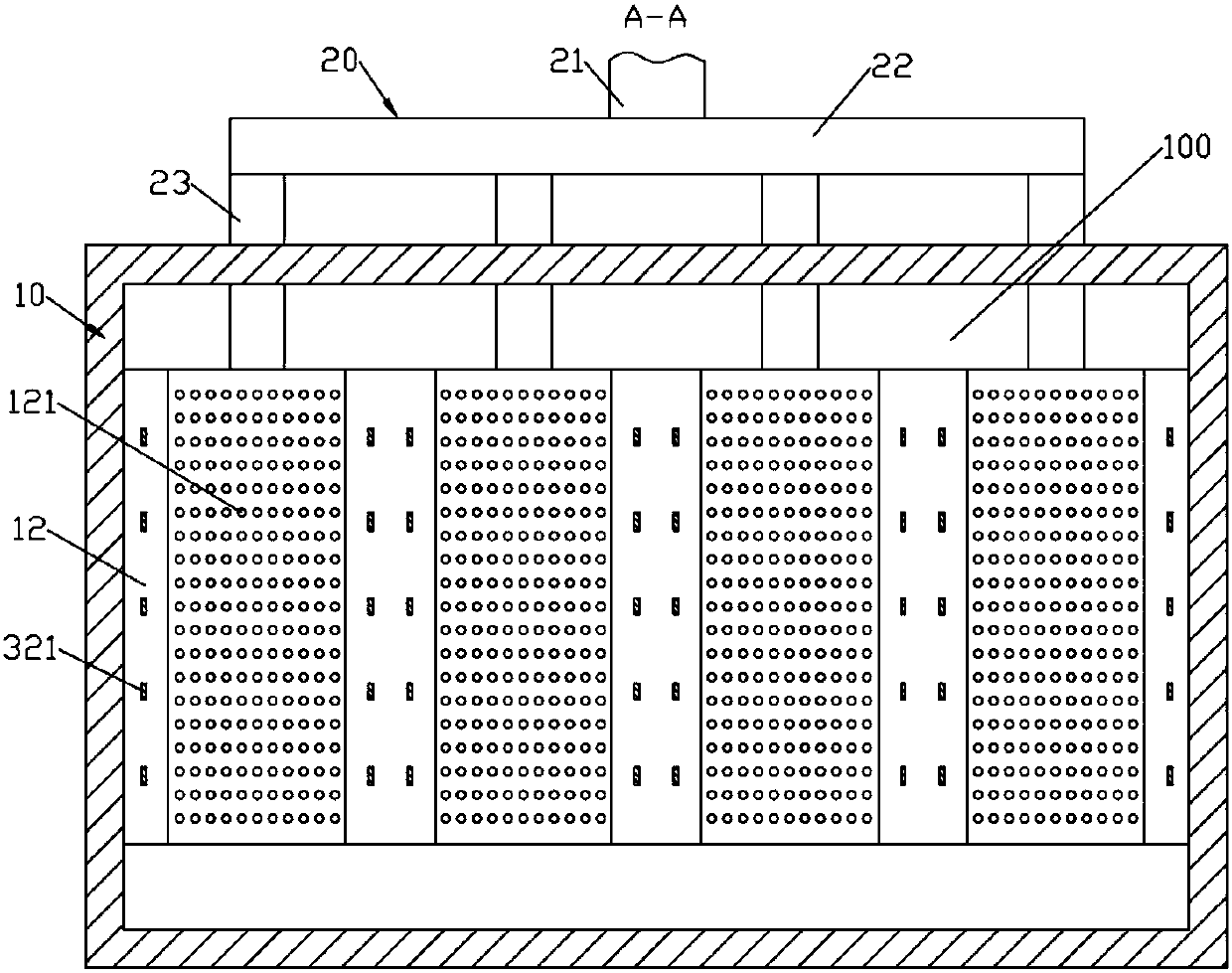

[0014] Such as figure 1 , figure 2 As shown, a rotary scraping dust remover, the main bracket 10, the intake branch pipe unit 20, the dust scraping device 30 and the dust falling device 40; the main bracket 10 is rectangular; the inside of the main bracket 10 is formed with a rectangular groove-shaped dust removal Slot 100; the middle part of the upper end surface of the main support 10 is formed with an exhaust pipe 11; the exhaust pipe communicates with the dust removal tank 100; a number of left and right side wall middle parts of the dust removal tank 100 are provided with a number of left and right dust separation boxes 12; the dust separation box 12 is a cuboid with a rectangular groove-shaped dust separation tank 120 formed on the lower end surface; the middle part of the upper side wall of the dust separation tank 120 is formed as an arc surface; Through the filter hole 121; the air branch pipe unit 20 includes a number of intake pipes 23; the air intake pipe 23 pass...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap