A 4000m using scanning radar 3 High-efficiency and low-consumption smelting method of blast furnace

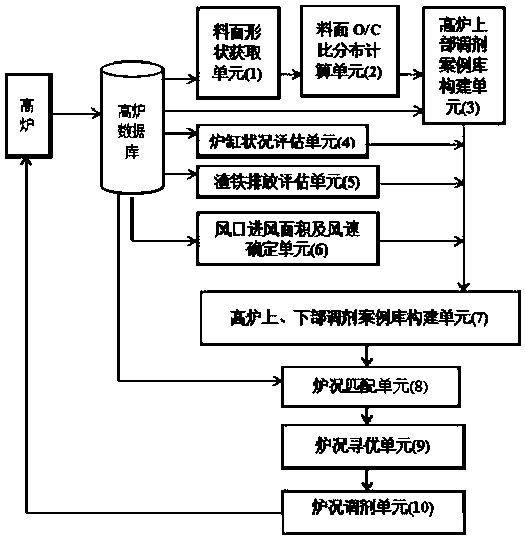

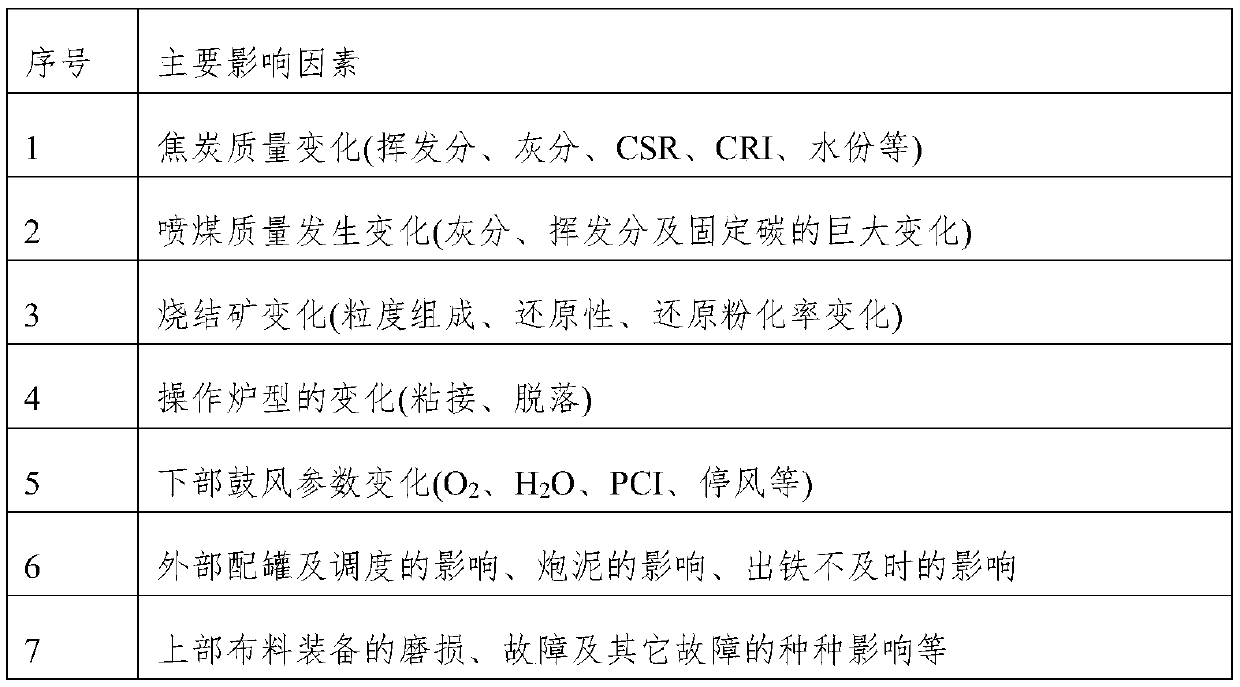

A scanning radar and blast furnace technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of not knowing the actual condition of the material surface, insufficient adjustment of the upper and lower parts, and large inertia, and achieve normal smelting with high efficiency and low consumption in blast furnaces, Avoid delays and mistakes, complete and timely results with furnace condition data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further illustrated by the following examples, but the present invention is not limited. All changes or equivalent substitutions that do not depart from the concept of the present invention are included in the protection scope of the present invention.

[0053] at 3200m 3 Take the blast furnace as an example to provide a real-time case.

[0054] The 3200m 3 The blast furnace is the main furnace of WISCO. There are 3 blast furnaces of this specification. These blast furnaces are equipped with bellless top, soft water closed circulation cooling system, INBA slag granulation system, complete furnace equipment, etc. The blast furnace generally has two levels. Control system, 3200m 3 The operation of the blast furnace reflects the typical operating characteristics of WISCO, 3200m 3 The properties of the main raw fuels used in the blast furnace are shown in Tables 9 and 10 below.

[0055] Table 9 into the charge coke quality

[0056] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com