A kind of preparation method of magnetic massage heating health care fabric

A health care fabric and fabric technology are applied in the preparation of magnetic therapy massage heating health care fabrics, improve the field of magnetic therapy effect of health care fabrics, can solve problems such as poor magnetic therapy effect, and achieve good magnetic therapy effect, good effect and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

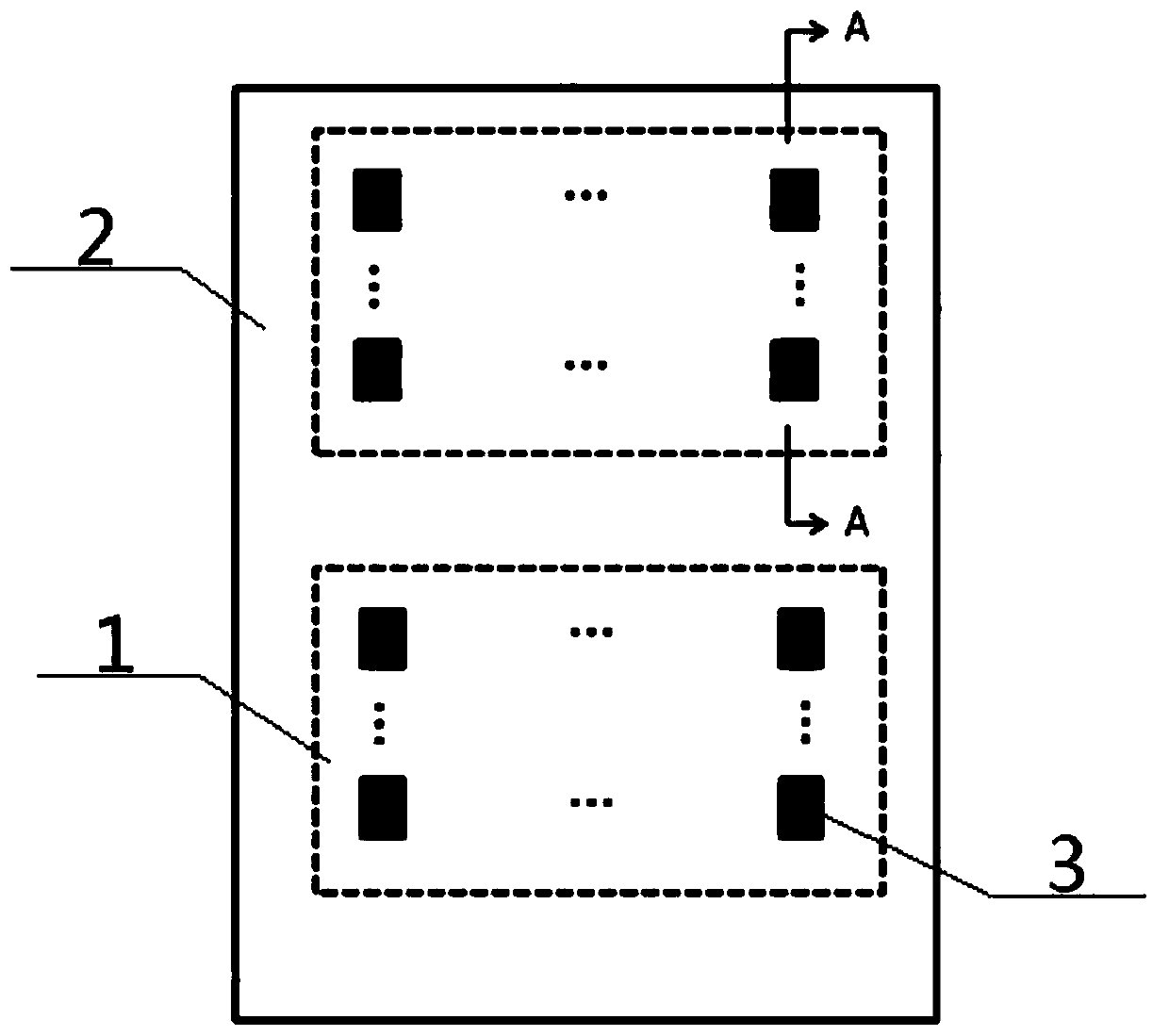

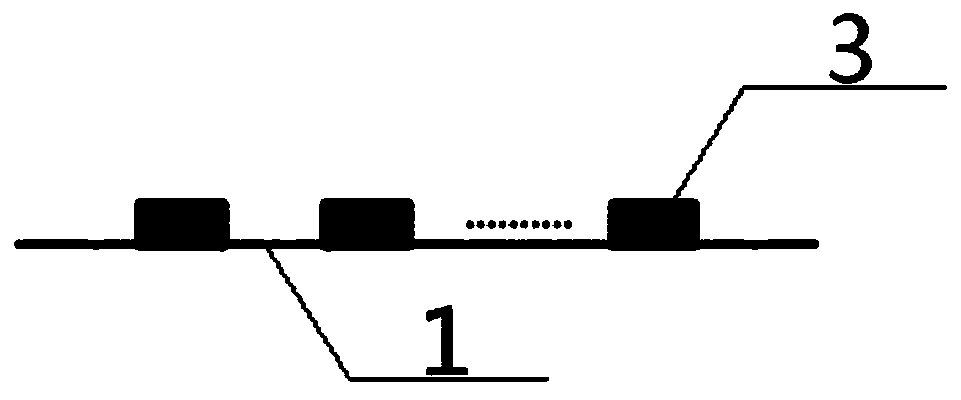

[0060] see Figure 1 to Figure 5 , a method for preparing a magnetic therapy massage heat-generating health care fabric; the preparation method sequentially includes a step of covering steel balls, a weaving step, washing and drying steps;

[0061] The step of covering the steel balls refers to: inserting the magnetic steel balls 4 at intervals into the interior of the water-soluble vinylon tube, the quantity of the magnetic steel balls 4 and their spacing positions are the same as the positions of the massage points 3 arranged along the weft direction of the health-care fabric. one-to-one correspondence;

[0062] The weaving step refers to: taking the warp and weft yarns to weave the health-care fabric, the health-care fabric includes a massage area 1 and a non-massage area 2 in an integrated structure, and a plurality of mutually independent massage points 3 are woven in the massage area 1 (preferably The massage point 3 in the massage area 1 is arranged in a matrix structu...

Embodiment 2

[0065] Basic content is the same as embodiment 1, the difference is:

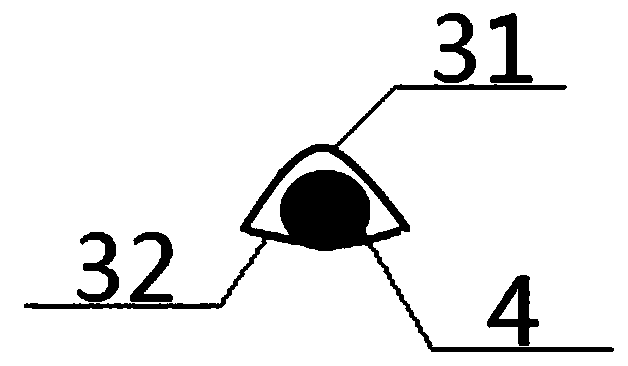

[0066] The fabric structure in the massage area 1 and the non-massage area 2 is plain weave or twill weave; the fabric structure between adjacent massage points 3 is plain weave or twill weave; The fabric structure of the connection is a plain weave or a twill weave. The upper fabric 31 is a single-layer fabric structure, the lower fabric 32 is a double-layer fabric structure, and the upper fabric 31 is a plain weave fabric.

Embodiment 3

[0068] Basic content is the same as embodiment 1, the difference is:

[0069] Described lower layer fabric 32 comprises lower top layer fabric 321, lower bottom layer fabric 322 arranged up and down, the weft yarn that described lower top layer fabric 321 weaves in weft direction comprises common weft yarn 5 and conductive carbon fiber yarn 6, and common weft yarn 5, conductive carbon fiber yarn The yarns are set at 6 intervals. The conductive carbon fiber yarn 6 is a monofilament structure or a multi-filament twisted structure (the conductive carbon fiber yarn 6 can be a single fiber, or two or more than two fibers twisted into a bundle. ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com