Artificial leather flocked on concave grooves and used for complete identification unit printing

A technology of identifying unit and artificial leather, applied in the field of artificial leather, can solve the problem of lack of layering, and achieve the effect of avoiding incomplete printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

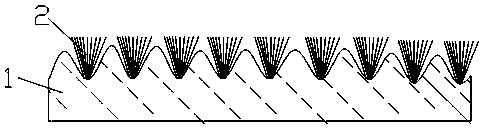

[0010] see figure 1 , the present invention relates to a kind of logo unit printed full-groove flocked artificial leather, the artificial leather includes PVC artificial leather 1, the lower surface of PVC artificial leather 1 is flat, the upper surface has patterns and patterns and several grooves 2 are arranged at intervals , There is fluff 3 in the groove 2. The PVC artificial leather 1 is composed of the following raw materials in parts by weight: 36-45 parts of polyvinyl chloride resin; 18-26 parts of plasticizer; 8-14 parts of toughening agent; 0.8-1.7 parts of stabilizer; 9-15 parts of filler parts; soybean oil 2~4 parts; lubricant 0.3~0.9 parts; black paste 0.5~1.1 parts.

[0011] The lower surface of the PVC artificial leather is compounded with a lining fabric layer, the lining fabric layer is a porous fabric, which includes a substrate made of porous fabric, and the porous fabric also includes a bottom layer and an information layer, and the bottom layer is directl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com