Wire and cable torsion stretching test machine

A tensile test, wire and cable technology, applied in the field of torsion mobile tensile testing machine, can solve the problems of safety hazards, charging failures, easy damage, etc., to achieve accurate and safe equipment work, effective overload protection, and improved clamping force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

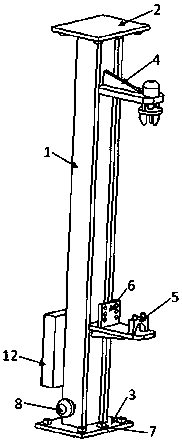

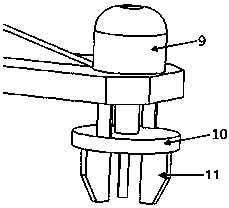

[0025] Such as figure 1 , figure 2 As shown, a wire and cable torsional tensile testing machine includes a column frame 1 and a lifting module installed on the column frame, a torsion module and an electrical box control system, and the upper and lower ends of the column frame 1 are respectively provided with column tops. Seat 2 and column base 3, guide rail is set on column frame 1, slide plate support frame 4 that can move up and down along the guide rail is set on column frame 1, cable fixing clamp block 5 and cable wire connection and fixing are set at the bottom of column frame 1 Module 6, the cable fixing clip 5 is controlled by two screws passing through the main body of the cable fixing clip 5 to control the tightness to fix the lower end of the test cable to prevent the cable from moving during the test; the cable wire connection module 6 is provided with several The conductive terminal connected to each insulated wire core in the cable is provided with an elastic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com