On-site defect-eliminating method for totally data-less failure of electric meter under type-II concentrator

A concentrator, no data technology, applied in the direction of instruments, measuring electricity, measuring electrical variables, etc., can solve the problems of low on-site processing efficiency, prone to wrong judgments, missed judgments, repeated judgments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

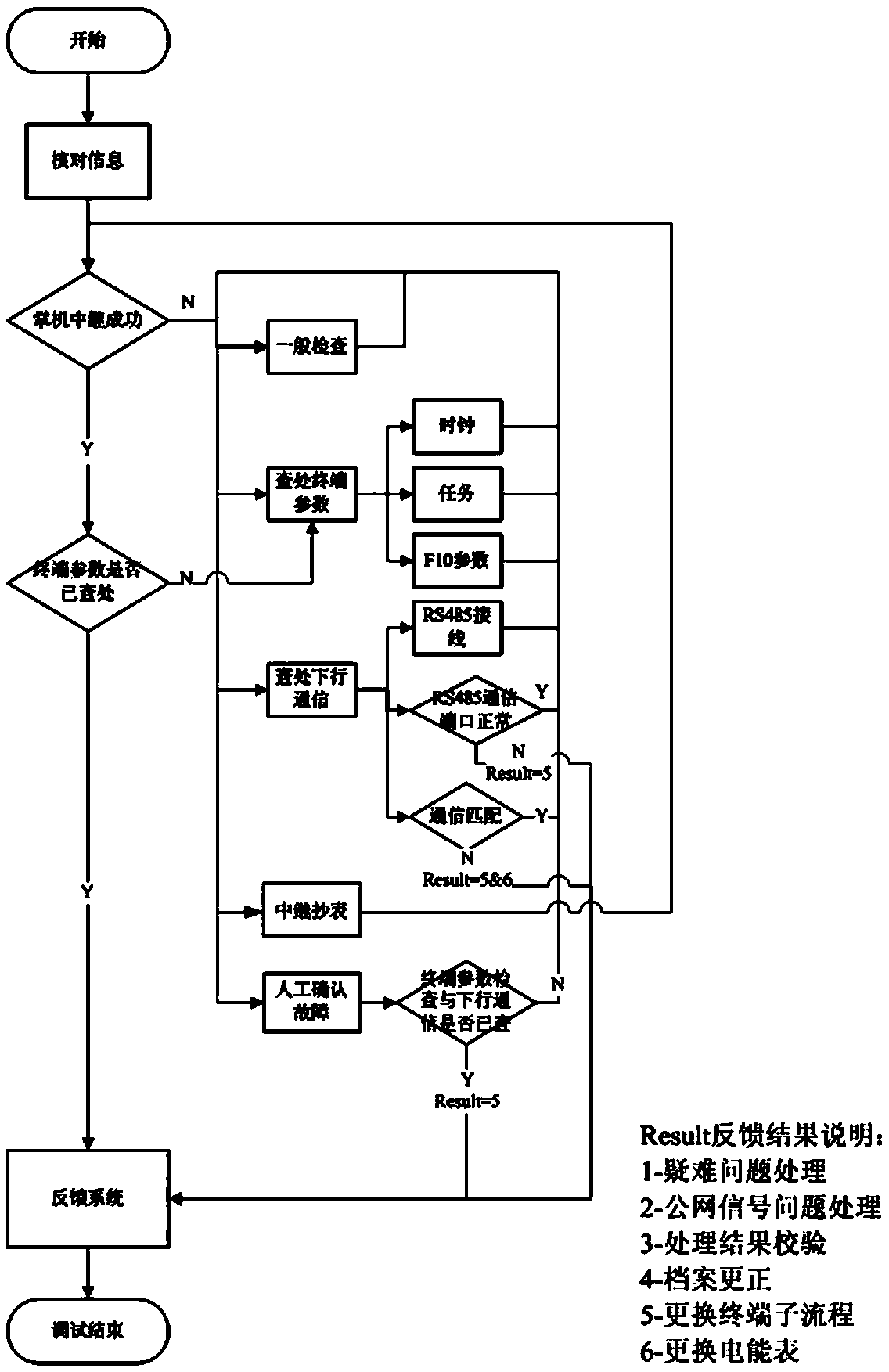

[0060] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0061] The present invention includes a preparation step and a defect elimination step.

[0062] Among them, the preparatory steps: summarizing the failure causes of all the electric meters under the type II concentrator with no data; selecting the optimized work flow for eliminating the absence of data on the electric meters under the type II concentrator; summarizing all the electric meters without data under the type II concentrator Troubleshooting method; the processing results are fed back to the on-site defect elimination system and stored;

[0063] When a fault is found, it enters the troubleshooting process at the fault site, where general inspection, terminal parameter investigation, and local communication are assigned according to historical fault information and operation and maintenance personnel's working habits through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com