Return force power generation device

A technology of generating sets and return springs, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve problems such as uneven water flow, turbine impact, turbine damage, etc., to avoid unlimited tilt, reduce impact pressure, and flexibly rotate The effect of the characteristic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

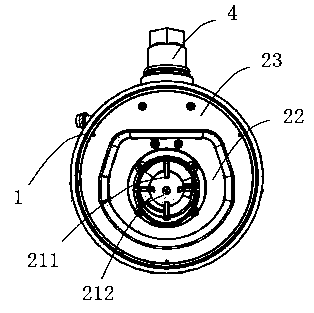

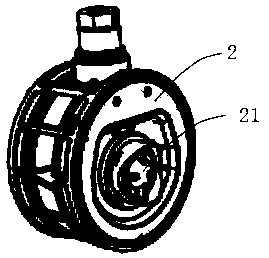

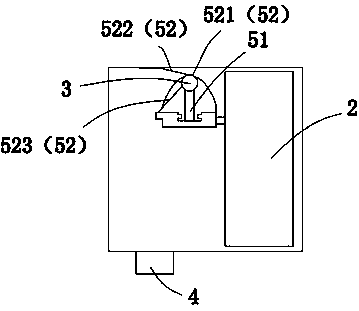

[0022] Such as Figure 1~4 As shown, a pull-back power generation device includes a device casing 1 with connecting through holes at both ends, a generator set 2 located in the device casing 1, a fixed shaft 3 fixed on the device casing 1, and can support the generator set 2 relative to the fixed The swing mechanism for vertically swinging the axis of the shaft 3 also includes a battery assembly 4 arranged outside the device casing 1 .

[0023] The generator set 2 includes a power generation core 21, a first flow surface 22 arranged on the outer periphery of the power generation core 21, and a second flow surface 23 connecting the outer periphery of the first flow surface 22 with the inner periphery of the connecting through hole at one end of the device casing 1. , the power generation core 21 is electrically connected to the battery assembly 4 .

[0024] The orientation of the fixed shaft 3 is such that when the generator set 2 swings to the lowest position, the first flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com