Forming Pocket And Method For Making A Forming Pocket

A cavity and external forming technology, which is applied in the direction of additive manufacturing, process efficiency improvement, application, etc., can solve the possibility that it cannot be used to determine the difference between the desired density of the forming sublayer and limit the compactness of the absorbing layer, and cannot be easily Modify the absorbing layer compactness and corresponding density etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In this specification, like elements common to the illustrated embodiments are indicated by like reference numerals.

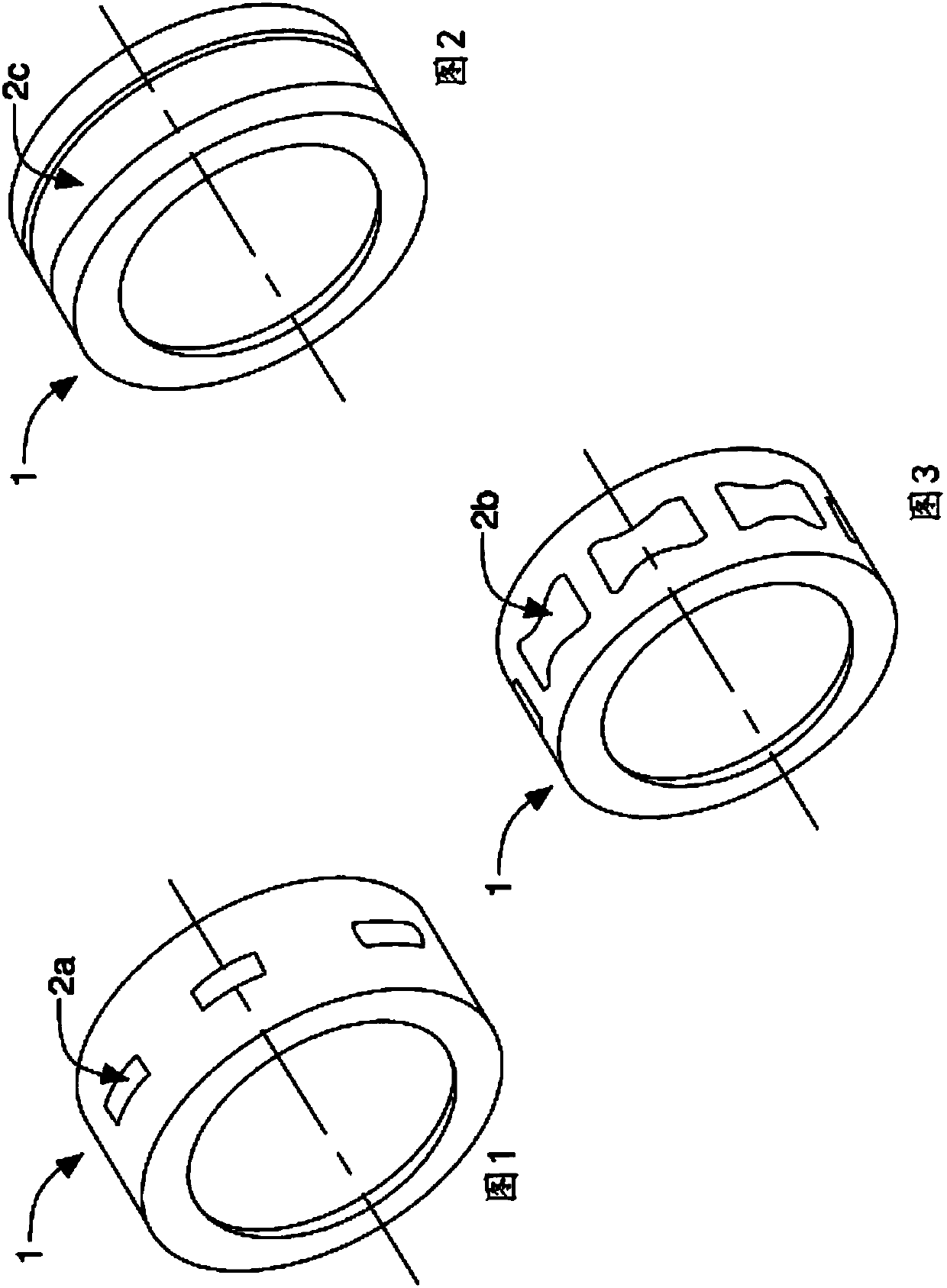

[0060] A forming device (not shown) for making absorbent fillings for hygiene articles comprises a forming conveyor for absorbent fillings. Already here Figure 1 to Figure 3 In particular, with reference to the prior art, 1 is used to represent the roller forming conveyor, and for the sake of brevity, details will not be repeated below.

[0061] The forming conveyor includes at least one forming cavity (not shown).

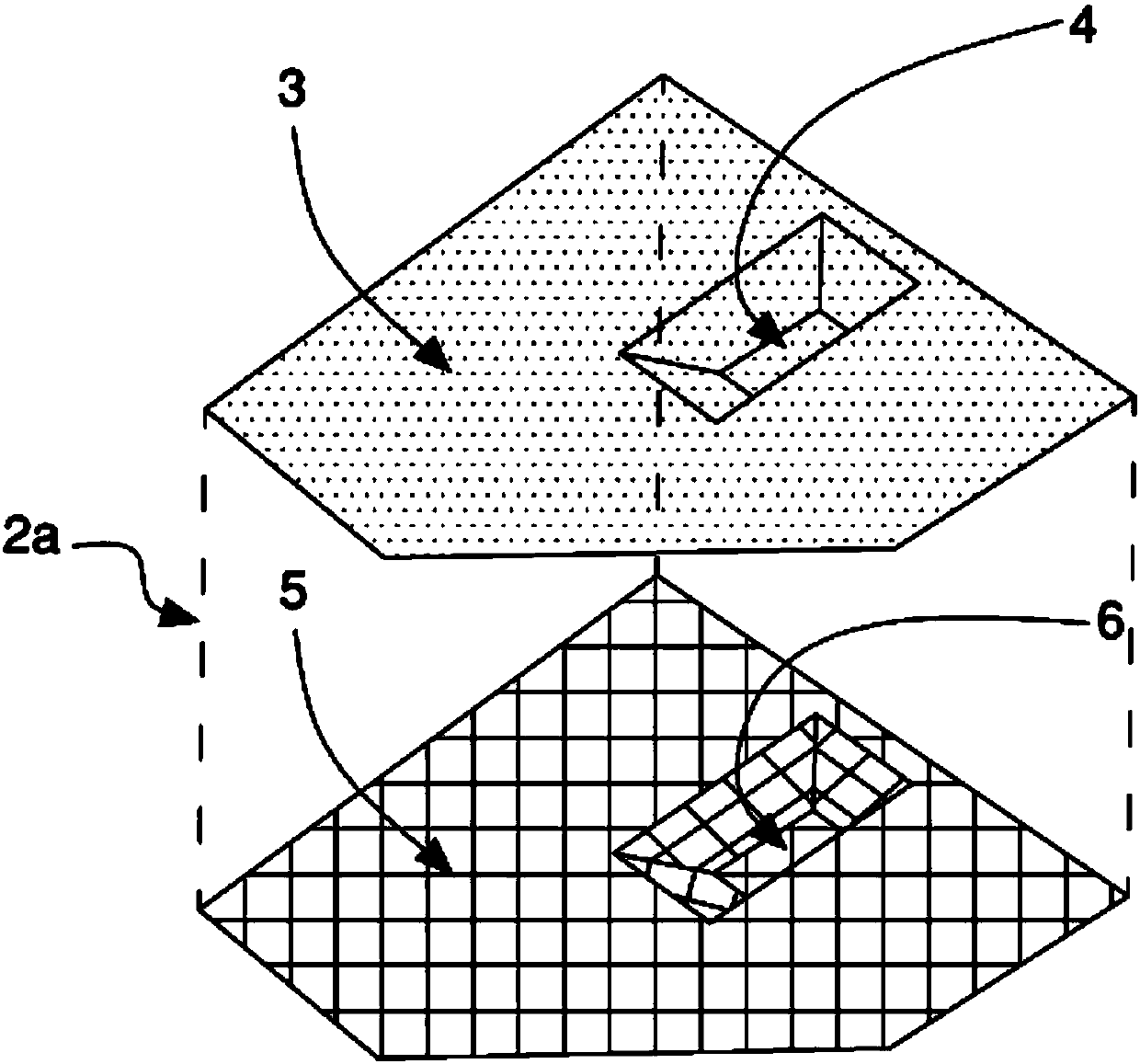

[0062] The forming cavity is adapted to receive particulate material and form therefrom an agglomerate of absorbent filling to be used as a hygiene article. The forming cavity comprises an outer forming substrate adapted to receive particulate material, made of metal mesh or sheet, provided with openings and having a shape conforming to the form of the absorbent filling to be made. exist Figure 4 The outer forming base indicated by 3 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com