Lithium ion battery

A lithium-ion battery and a combination of technologies, applied in the field of lithium-ion batteries, can solve problems such as central axis positioning that cannot be avoided, and achieve the effect of easy and cheap production and easy welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

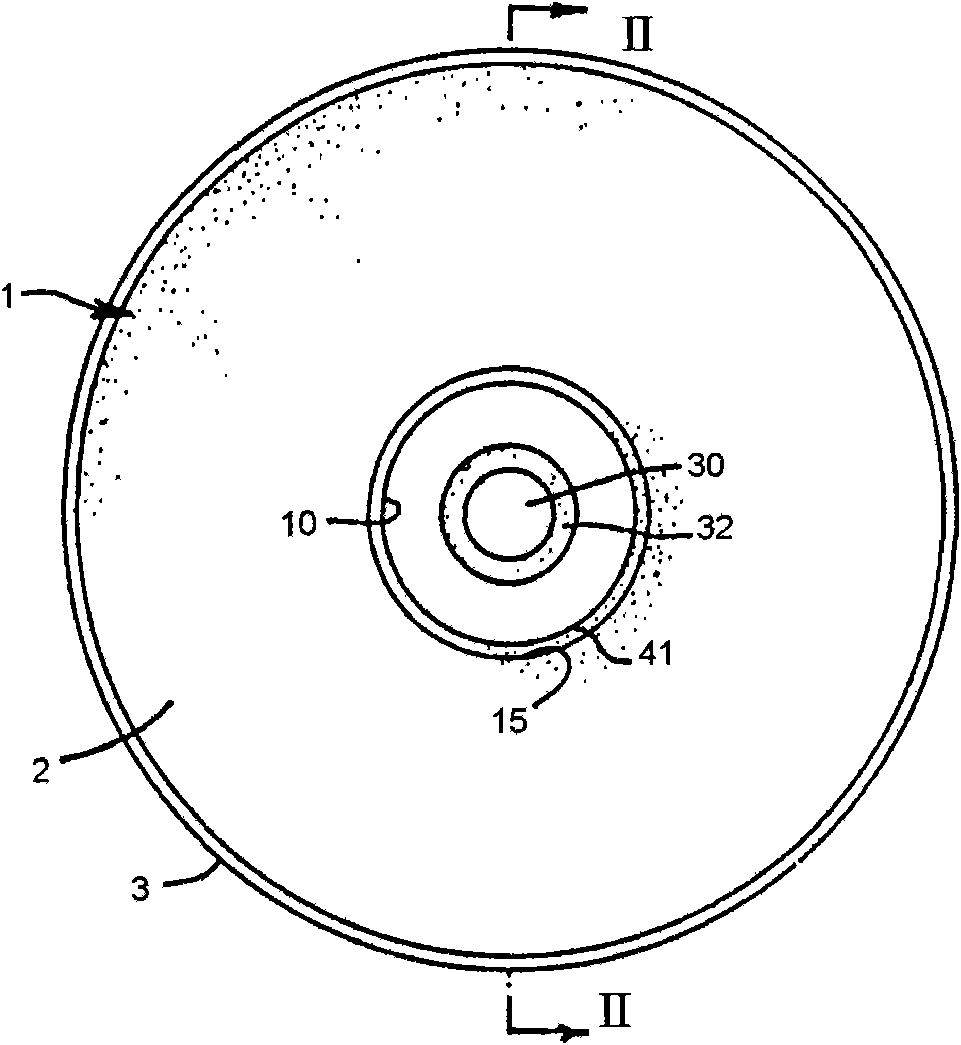

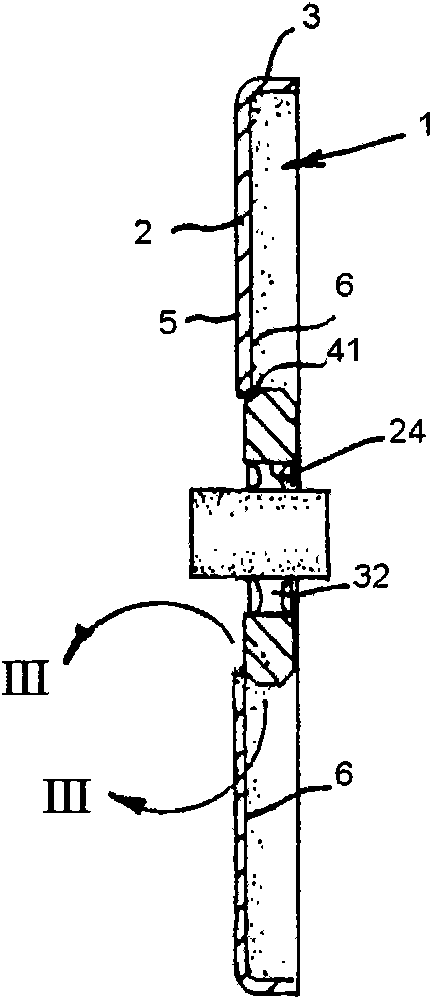

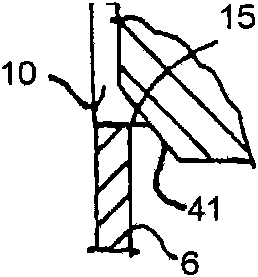

[0015] According to the preferred embodiment of the present invention, as shown in the figure, the reference number 1 represents a cover-shaped lithium-ion battery cover plate with a web portion 2 and a flange 3 . The web 2 has an outer plane 5 and an inner plane 6 approximately parallel to the outer plane 5 . Cover plate 1 is a circular plane, in the center of which there is a circular through hole 10 delimited by surface 12 which intersects at right angles to outer surface 5 and inner surface 6 and forms a flange 15 with these planes. If the through hole 10 is punched neatly, the flange 15 is the point line of the right angle. However, for example, when making a stain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com