Sand screening equipment

A technology for screening equipment and sand particles, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of non-removable, inconvenient collection, long time-consuming screening, etc., and achieve the effect of improving service life and not being easy to corrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

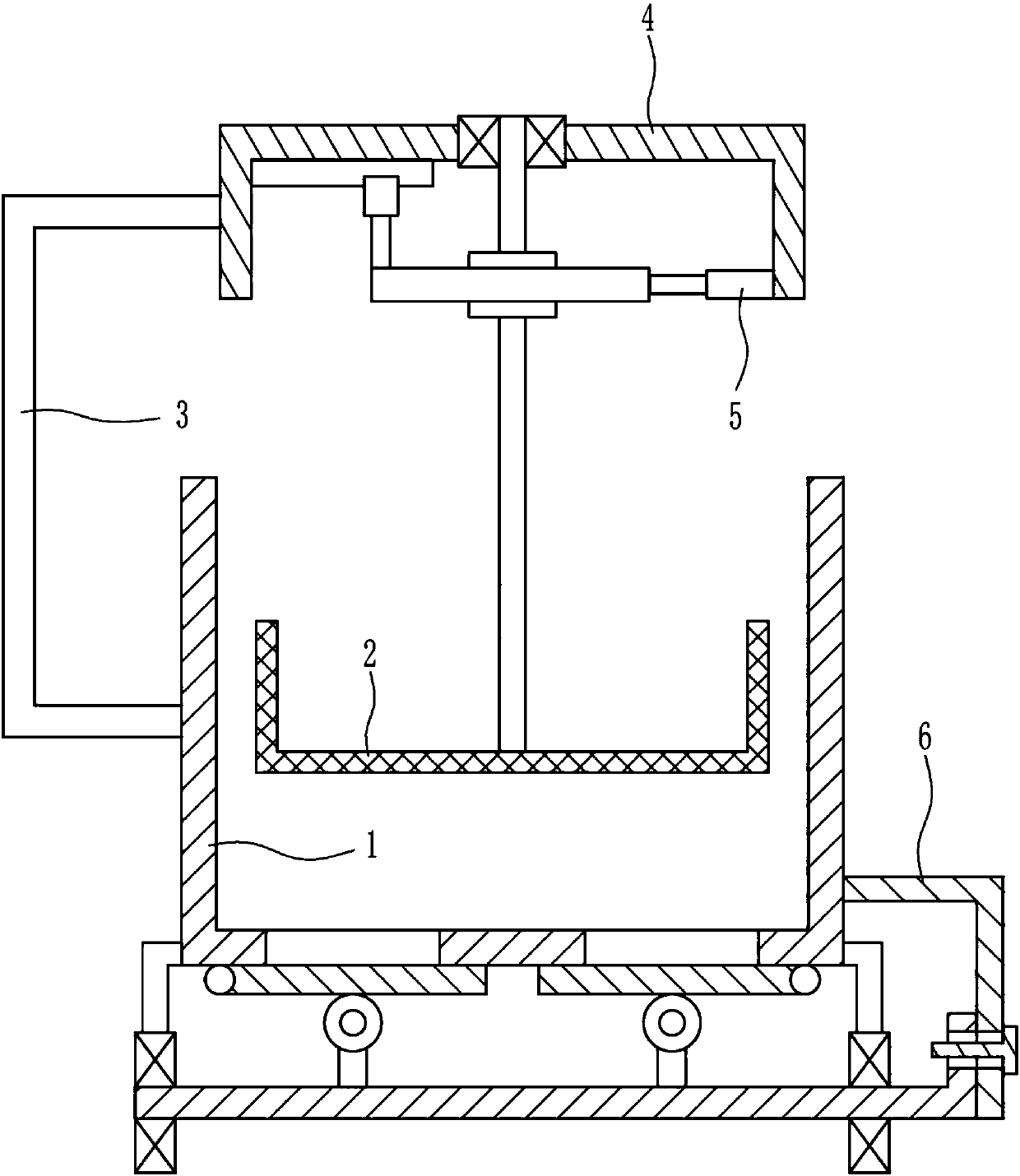

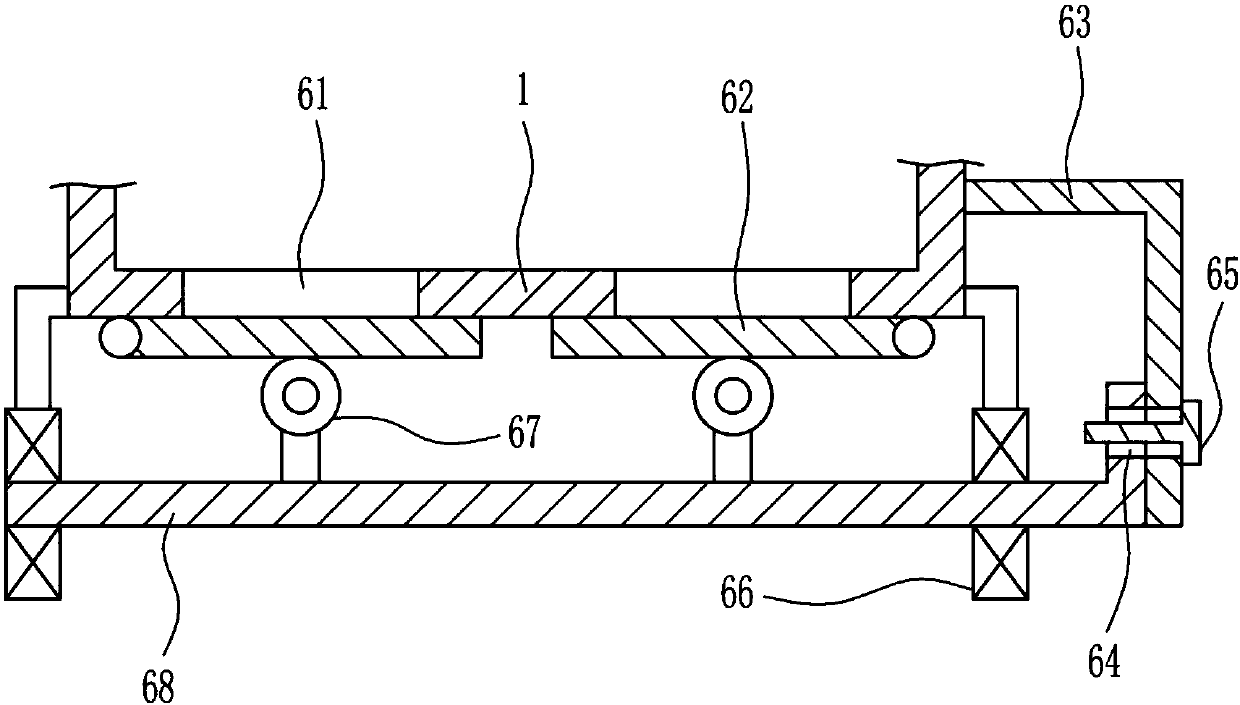

[0040] A sand screening equipment such as Figure 1-7 As shown, it includes a frame body 1, a screen frame 2, a first connecting rod 3, an installation frame 4, a rotating mechanism 5 and a switch mechanism 6. The frame body 1 is provided with a screen frame 2, and the upper left side of the frame body 1 is connected with a second A connecting rod 3, the end of the first connecting rod 3 is connected with a mounting frame 4, the bottom of the mounting frame 4 is provided with a rotating mechanism 5, and the bottom of the frame body 1 is provided with a switch mechanism 6.

Embodiment 2

[0042] A sand screening equipment such as Figure 1-7 As shown, it includes a frame body 1, a screen frame 2, a first connecting rod 3, an installation frame 4, a rotating mechanism 5 and a switch mechanism 6. The frame body 1 is provided with a screen frame 2, and the upper left side of the frame body 1 is connected with a second A connecting rod 3, the end of the first connecting rod 3 is connected with a mounting frame 4, the bottom of the mounting frame 4 is provided with a rotating mechanism 5, and the bottom of the frame body 1 is provided with a switch mechanism 6.

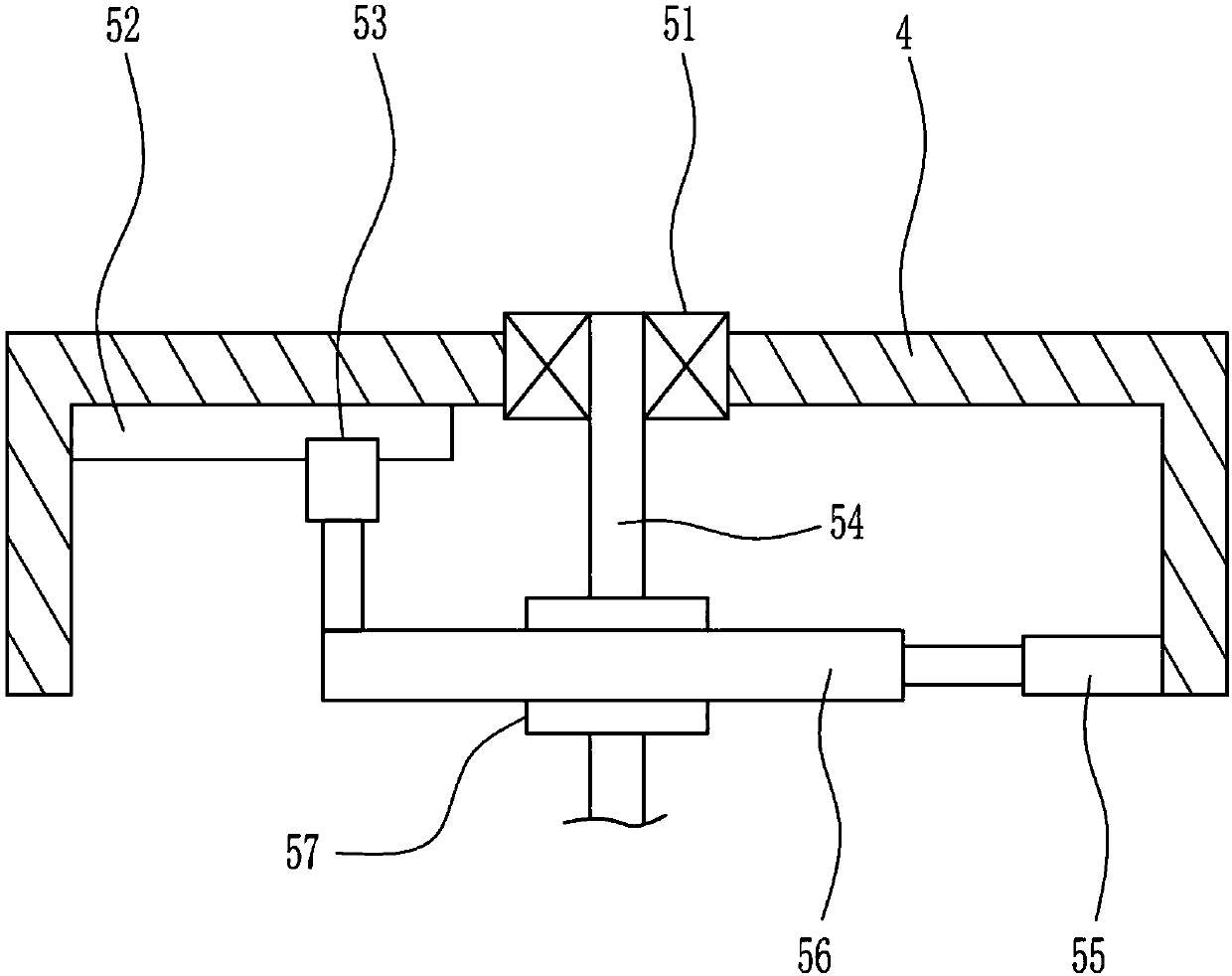

[0043] The rotating mechanism 5 includes a first bearing seat 51, a slide rail 52, a slide block 53, a first rotating rod 54, an electric push rod 55, a rack 56 and a gear 57, and the middle part of the mounting frame 4 is connected with the first bearing seat 51, and the second A bearing seat 51 is connected with a first rotating rod 54, the bottom of the first rotating rod 54 is connected with the top in ...

Embodiment 3

[0045] A sand screening equipment such as Figure 1-7 As shown, it includes a frame body 1, a screen frame 2, a first connecting rod 3, an installation frame 4, a rotating mechanism 5 and a switch mechanism 6. The frame body 1 is provided with a screen frame 2, and the upper left side of the frame body 1 is connected with a second A connecting rod 3, the end of the first connecting rod 3 is connected with a mounting frame 4, the bottom of the mounting frame 4 is provided with a rotating mechanism 5, and the bottom of the frame body 1 is provided with a switch mechanism 6.

[0046] The rotating mechanism 5 includes a first bearing seat 51, a slide rail 52, a slide block 53, a first rotating rod 54, an electric push rod 55, a rack 56 and a gear 57, and the middle part of the mounting frame 4 is connected with the first bearing seat 51, and the second A bearing seat 51 is connected with a first rotating rod 54, the bottom of the first rotating rod 54 is connected with the top in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com