An inner hexagon telescopic adjustable wrench

A technology of hexagonal wrench and adjustable wrench, which is applied in the direction of wrenches, manufacturing tools, screwdrivers, etc., and can solve problems such as low work efficiency, troublesome use, and inability to disassemble and assemble hexagon socket screws.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

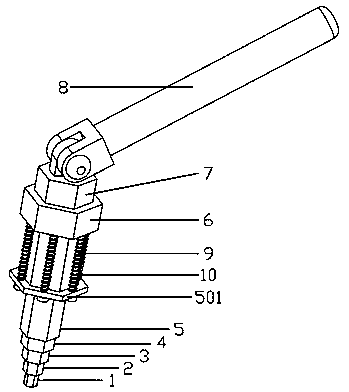

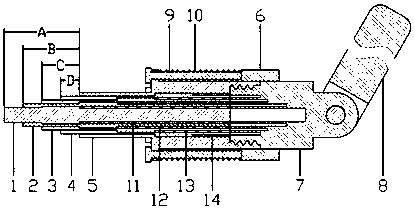

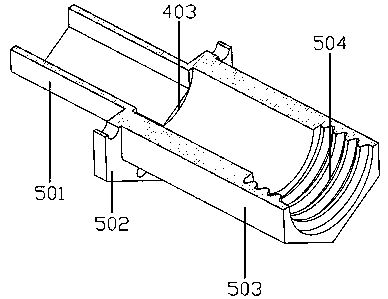

[0025] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings: It should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

[0026] Such as Figures 1 to 8As shown, a hexagonal telescopic adjustable wrench, including M4 hexagonal wrench 1, M6 hexagonal wrench 2, M8 hexagonal wrench 3, M10 hexagonal wrench 4, M12 hexagonal wrench 5, the M12 hexagonal wrench 5 The M10 inner hexagonal wrench 4 is installed, the M8 inner hexagonal wrench 3 is installed in the M10 inner hexagonal wrench 4, the M6 inner hexagonal wrench 2 is installed in the M8 inner hexagonal wrench 3, the M6 inner hexagonal wrench 2 The M4 hexagonal wrench 1 is installed in the hexagonal wrench 2; the tail part 503 of the M12 inner hexagonal wrench is equipped with a sealing block 7, and the tail part 703 of the sealing block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com