Cinnabar embossed picture preparation device

A technology for preparing devices and reliefs, applied in special decorative structures, decorative arts, etc., can solve problems such as inhalation of cinnabar dust and damage to human health, and achieve the effect of reducing manual operations and avoiding damage to human health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

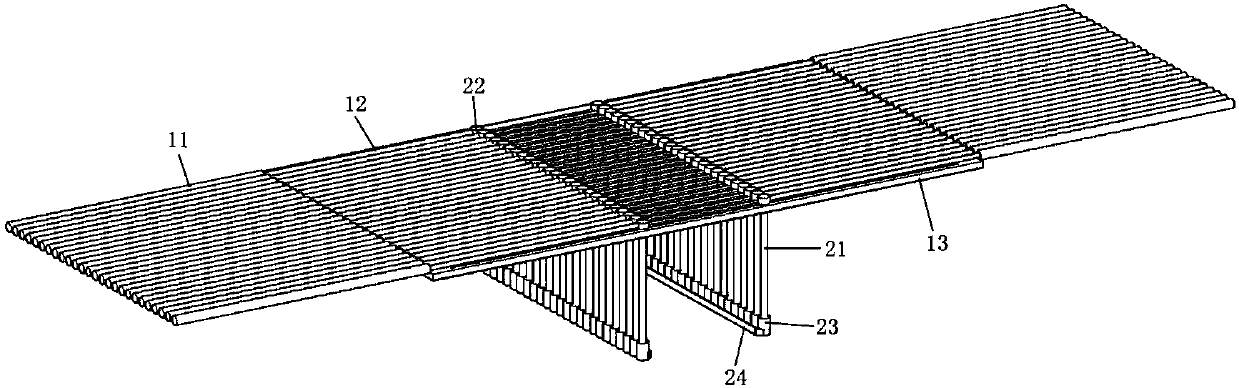

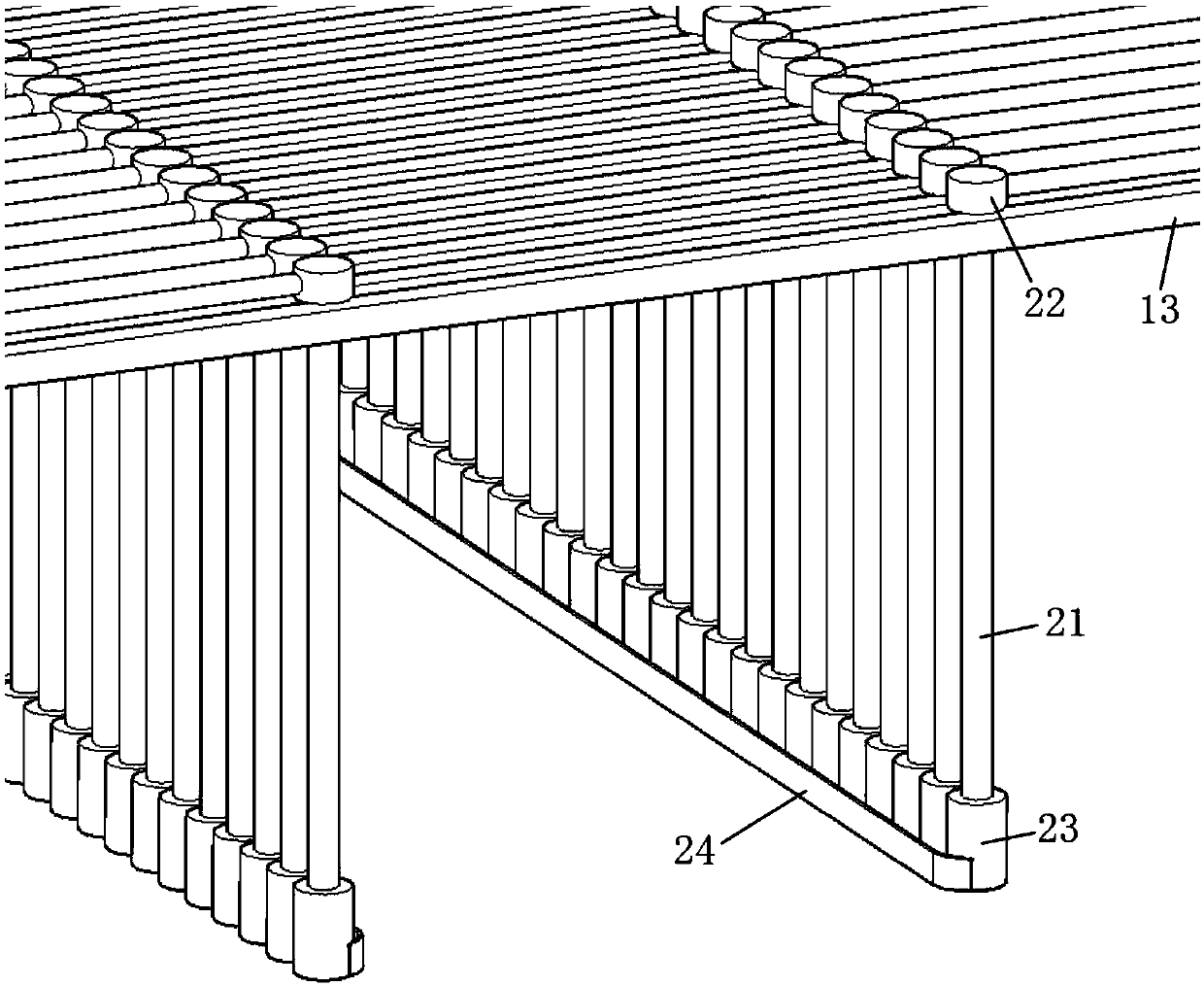

[0018] Such as figure 1 , figure 2 A kind of cinnabar relief painting preparation device shown comprises fixed rod 11, moving rod 12, frame body 13, straight rod 21, positioning block 23; There are a plurality of parallel bar grooves on the described frame body 13, vertically pass through in the bar groove There is a straight rod 21, the upper end of the straight rod 21 is horizontally fixed on the front end of the moving rod 12, the rear end of the moving rod 12 is telescopic in the fixed rod 11, and the lower end of the straight rod 21 is fixed with a cylindrical positioning block 23; The body 13 extends on both sides, and the axis of the moving rod 12 is parallel to the axis of the slot through which the straight rod 21 passes, and the fixed rod 11 is located outside the frame body 13; the diameter of the positioning block 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com