Sand box molding line and its working method

A sand box molding and sand box technology, applied in manufacturing tools, casting molding equipment, foundry workshops, etc., can solve the problems of long production cycle, unreasonable layout, and long overhead crane time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

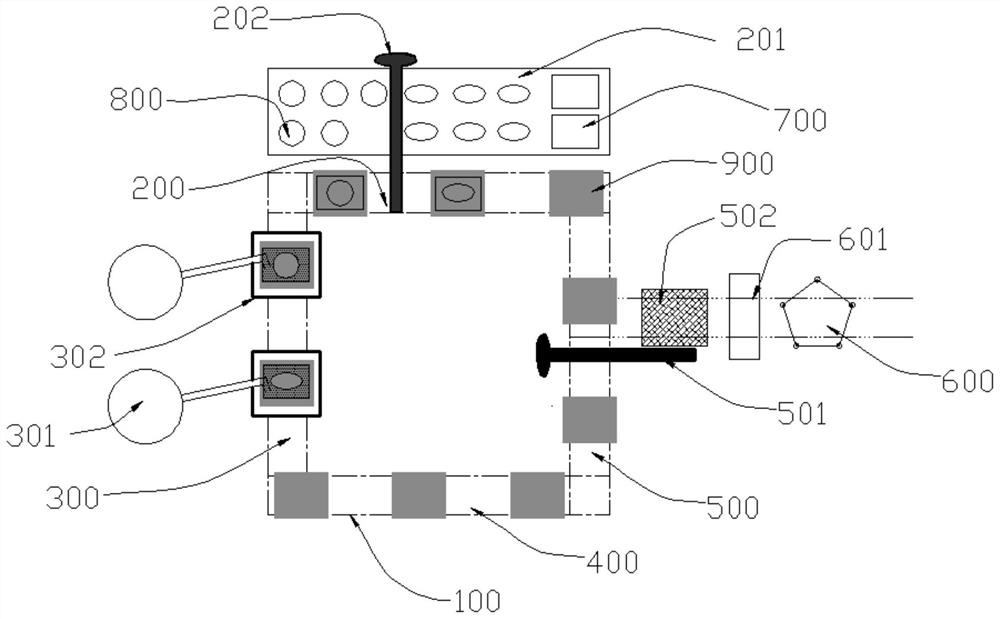

[0027] A sand box molding line, such as figure 2 Shown includes: self-flowing double-speed conveying line 100, box buckling station 200, sand filling and vibrating station 300, hardening station 400, and demoulding station 500.

[0028] Such as figure 2 As shown, the buckle box station 200, the sand filling and vibration station 300, the hardening station 400 and the demoulding station 500 are distributed counterclockwise on the four sides of the rectangle in sequence, and the box box station 200 includes a storage warehouse and Box-locking manipulator, the box-locking manipulator can cover the storage warehouse 201 and the box-locking station 200, and the box-locking manipulator 202 is used to grab the mold 800 and sand box 700 to be used from the storage warehouse 201 to the mobile molding Platform 900; the sand filling and vibrating station 300 includes a sand lowering device 301 and a vibration compacting table 302, the sand lowering device 301 is used to flow sand into...

Embodiment 2

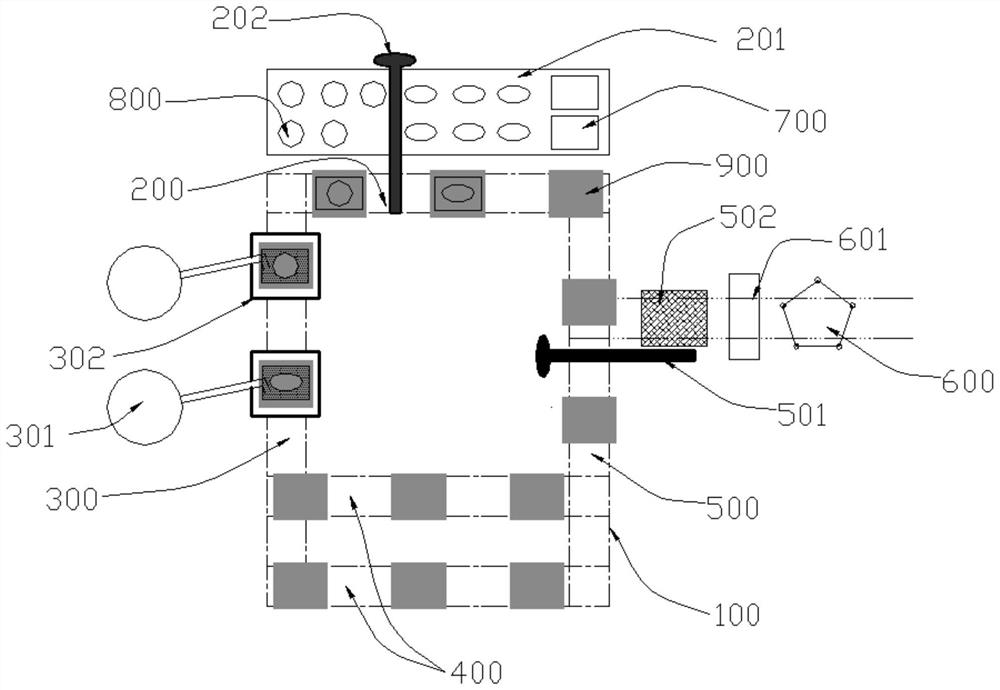

[0039] A sand box 700 molding line, such as figure 2 Shown includes: self-flowing double-speed conveying line 100, buttoning station 200, sand filling and vibrating station 300, hardening station 400, demoulding station 500 and intelligent control system;

[0040] Box box station 200, sand filling and vibration station 300, hardening station 400 and demoulding station 500 are distributed counterclockwise on the four sides of the rectangle in sequence. The box box station 200 includes a storage warehouse 201 and box box Manipulator 202, which can cover the storage warehouse 201 and the deduction box station 200, the deduction box manipulator 202 is used to grab the mold 800 and the sand box 700 to be used from the storage warehouse 201 to the mobile molding Platform 900; the sand filling and vibrating station 300 includes a sand lowering device 301 and a vibration compacting table 302, the sand lowering device 301 is used to flow sand into the sand box 700, and the vibration c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com