Method for discriminating middle leaves and upper leaves of flue-cured tobaccos

A discrimination method and technology for flue-cured tobacco, applied in the measurement of color/spectral characteristics, etc., can solve the problems of inability to use automatic sorting of tobacco leaves, and achieve the effects of low detection environment and sample requirements, high accuracy, and simple detection process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

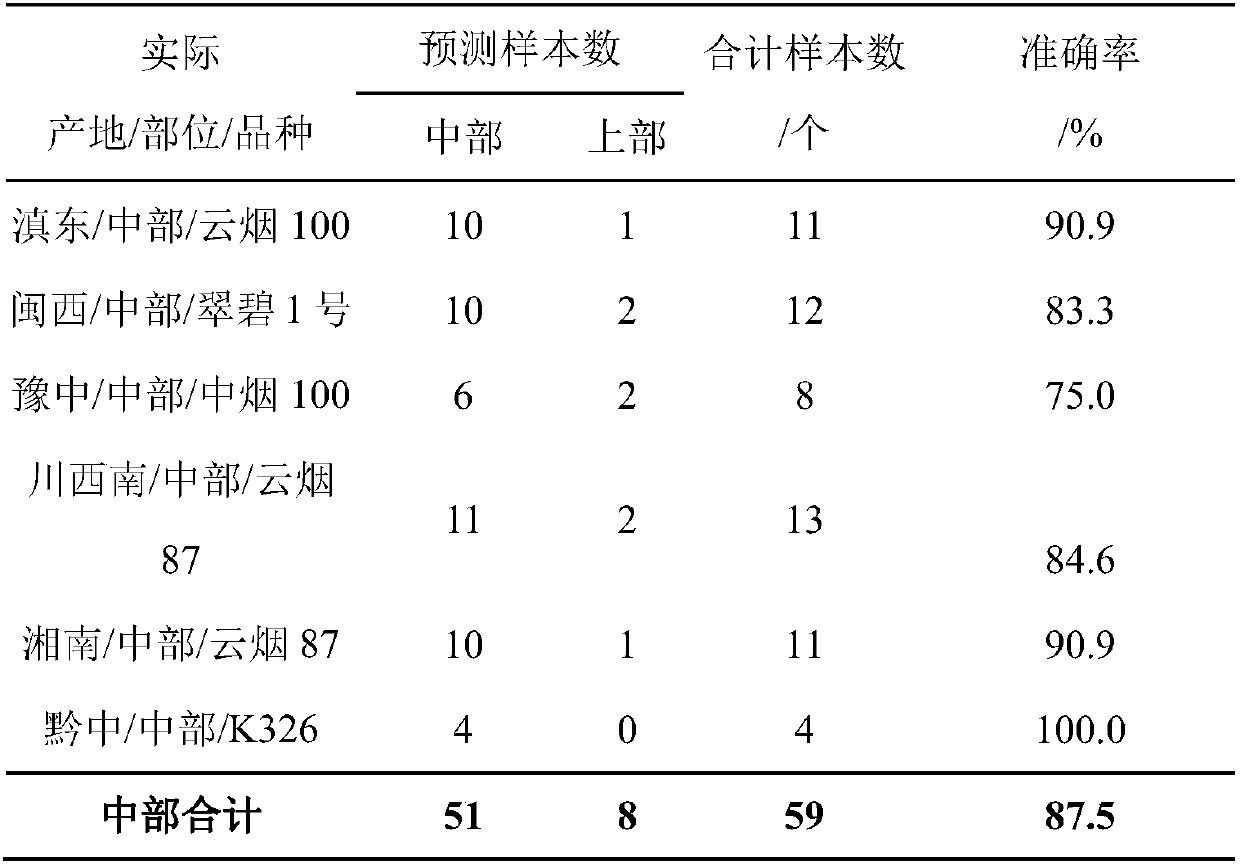

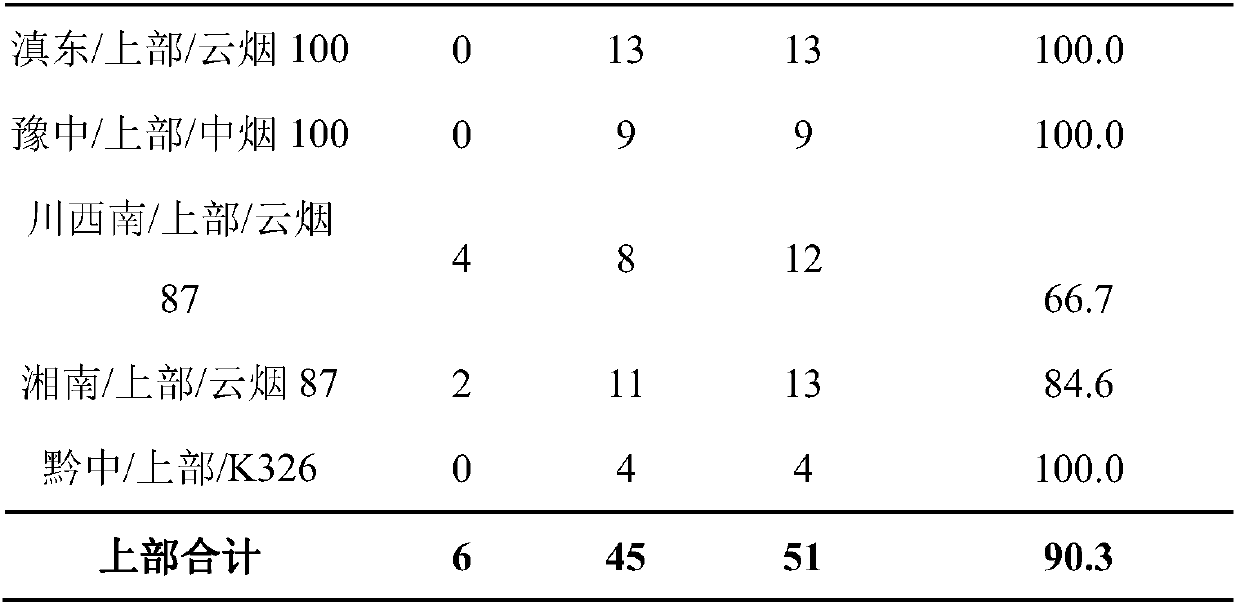

[0024] The method for discriminating between the flue-cured tobacco middle leaf and the upper leaf of the present embodiment comprises the following steps:

[0025] 1) Establish a discriminant model for the difference between the whiteness index of the front and back of the tobacco leaf and the position of the tobacco leaf, as follows:

[0026] Middle part: Y=-1.102–0.248×difference of whiteness index of front and back (1);

[0027] Upper part: Y=-1.277+0.296×difference of whiteness index of front and back (2);

[0028] 2) Use the Color-Eye 7000A spectrophotometer to quantitatively measure the color index of tobacco leaves. Take 10 representative tobacco leaves for each sample to be discriminated, and select 4 measurement points symmetrically from the front and back of each tobacco leaf in the middle of the leaf. Each measurement point is automatically Take the average value after measuring twice, take 20 measured values on the front and back sides of each sample to be disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com