Dotted conductive composite coating for fuel cell metal plate

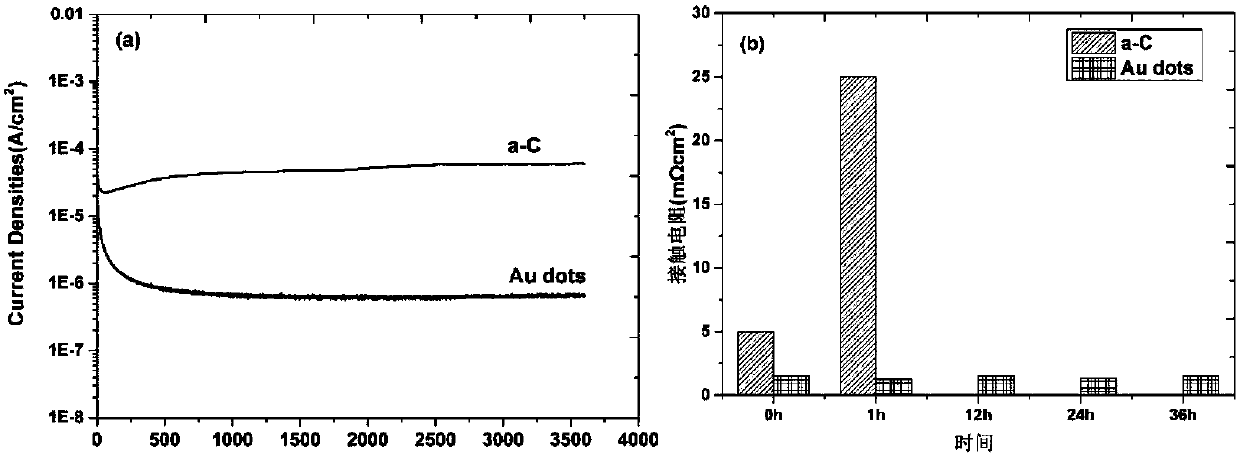

A metal plate and composite coating technology, which is used in fuel cell components, fuel cells, battery electrodes, etc., can solve the problems of difficulty in meeting the commercialization needs of metal plates, coating surface oxidation, and increased contact resistance. Achieve the effect of good electrical conductivity, strong corrosion resistance and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

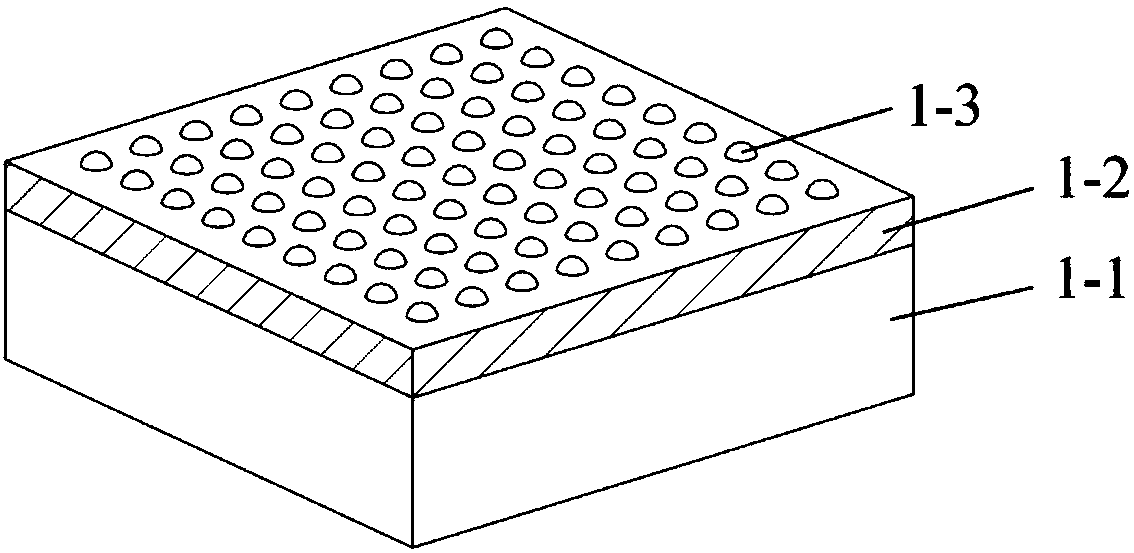

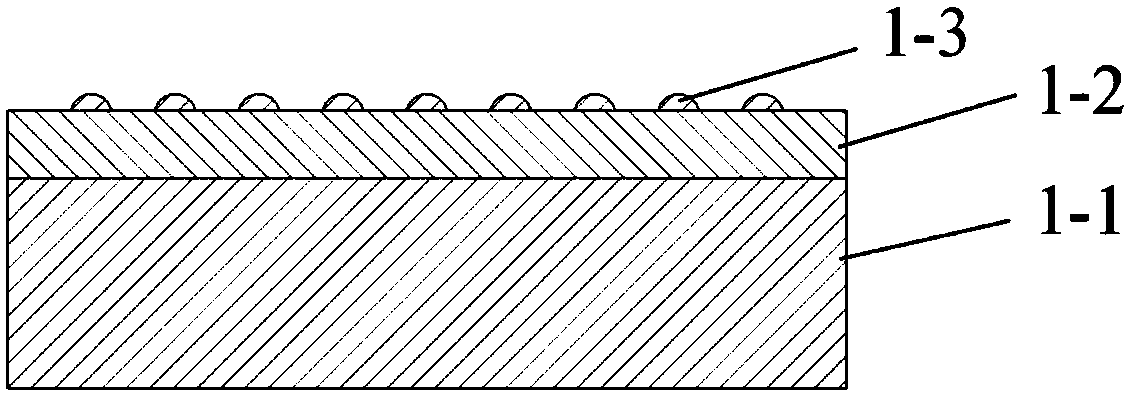

[0041] A dot-shaped conductive composite coating for metal pole plates of fuel cells, its structure is as follows Figure 1-2 As shown, the point-shaped conductive composite coating is firstly deposited on the upper surface of the metal plate 1-1 with a metal layer 1-2, and in this embodiment, a metal W with a thickness of 5 nm is deposited. Then, point metals 1-3 are deposited on the pre-deposited coating. In this embodiment, the noble metal Pt with a thickness of 1 nm is deposited.

Embodiment 2

[0043] A dot-shaped conductive composite coating for metal pole plates of fuel cells, its structure is as follows Figure 3-4 As shown, the dot-shaped conductive composite coating is firstly deposited on the upper surface of the metal pole plate 2-1 with a metal layer 2-2, and metal Ni with a thickness of 10 nm is deposited. Then deposit point-like metal 2-3 on the pre-deposited coating, what is deposited is noble metal Y with a thickness of 1nm, and the coverage is 10%, and then continue to deposit metal layer 2-4 on the point-like metal 2-3 , the metal Nb with a thickness of 10 nm is deposited, and the dot-like metal 2-5 is deposited on the metal layer 2-4, and the noble metal Ag with a thickness of 10 nm is deposited.

Embodiment 3

[0045] A dot-shaped conductive composite coating for metal pole plates of fuel cells, its structure is as follows Figure 5-6 As shown, the dot-shaped conductive composite coating first pre-deposits an oxide layer 3-2 on the upper surface of the metal plate 3-1, and what is deposited is WO with a thickness of 1nm. 2 , and then deposit point-like metal 3-3 on the pre-deposited coating, which is the noble metal Au with a thickness of 10nm, embedded between oxides.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com