Fire-hydrant cabinet

A fire hydrant box, fire fighting technology, applied in fire rescue and other directions, can solve the problem of inconvenient winding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

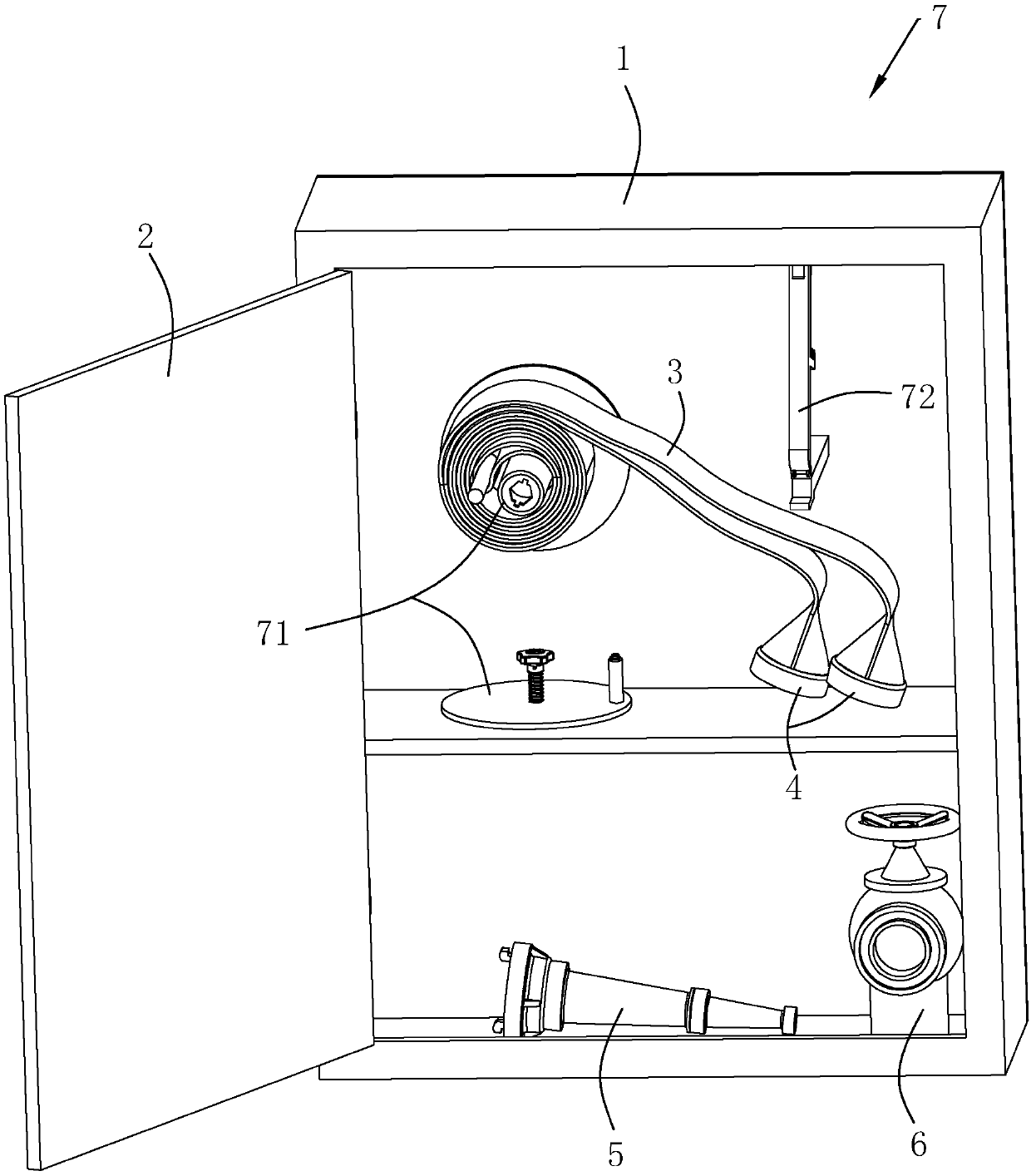

[0039] Fire hydrant box, see figure 1 and figure 2 As shown, it includes a box body 1, a box door 2, a fire hose 3, a joint 4 fixedly connected to both ends of the fire hose 3, a fire hose 5, a fire hydrant head 6, and a storage device 7 for winding the fire hose 3 , on fire hose 3, spray red paint at 20cm away from the center, both sides.

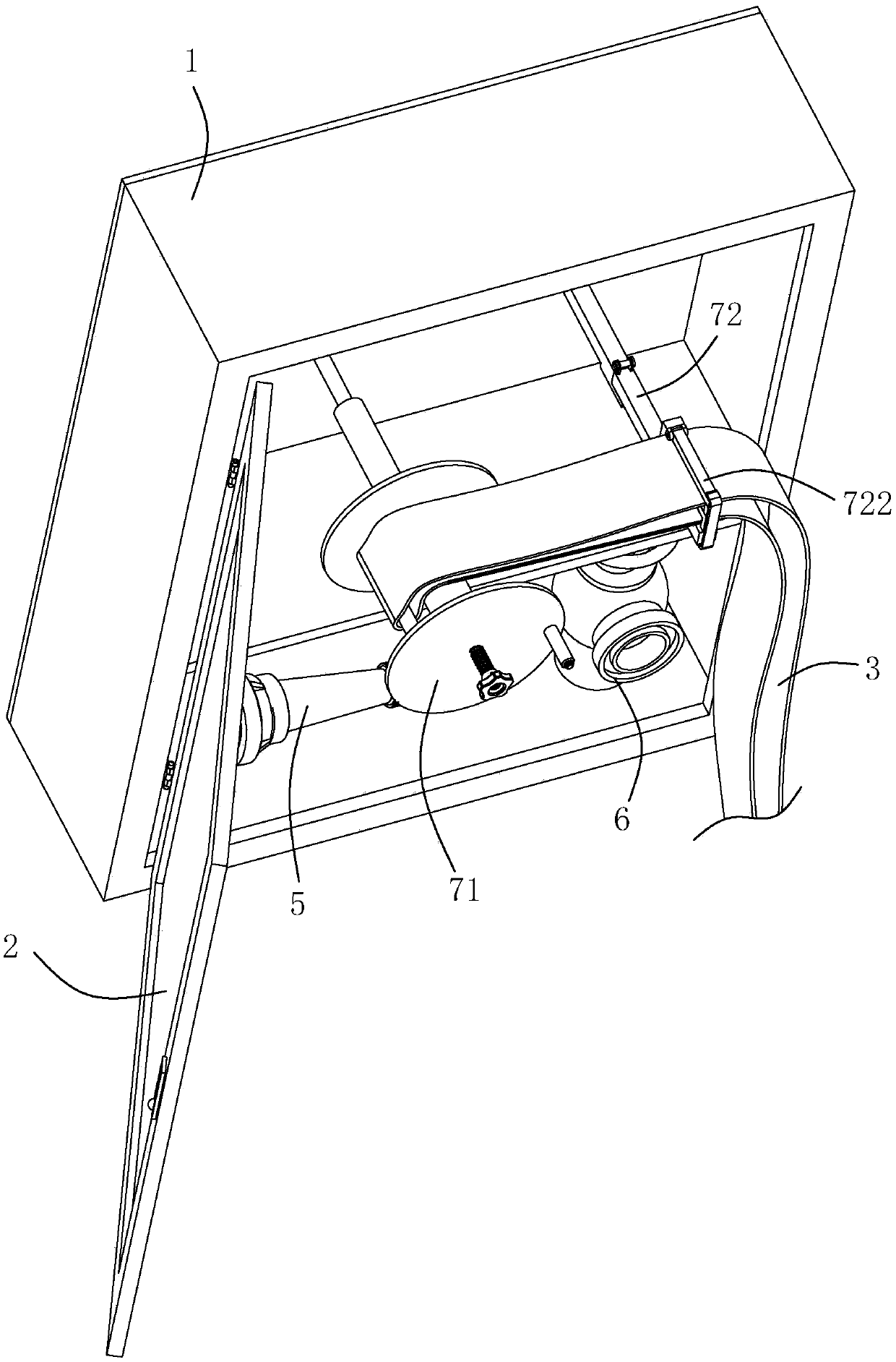

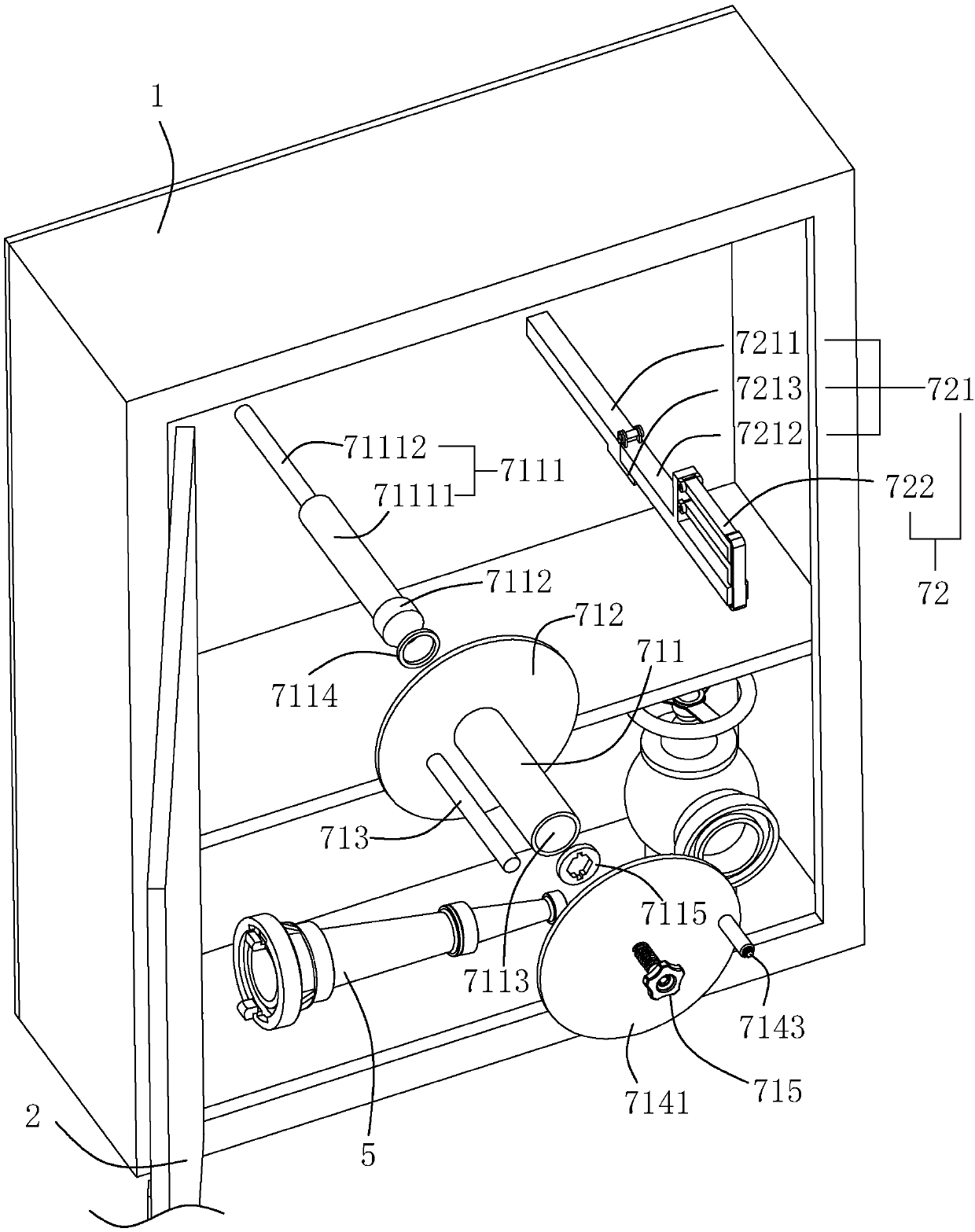

[0040] refer to figure 2 and image 3 As shown, the storage device 7 includes a storage wheel 71 for winding the fire hose 3 and a sorting mechanism 72 that automatically arranges the fire hose 3 so that the fire hose 3 is rolled on the storage wheel 71 during the winding process.

[0041] refer to figure 2 and image 3 As shown, the storage wheel 71 includes a runner 711 that is rotatably connected to the box body 1, a side plate 712 that is fixedly connected to the side plate 712 of the side plate 711 near the box body 1, a cylinder 713 that is fixedly connected to the side plate 712, and is connected to the wheel. 711 inserts t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com