A fully automatic saddle stitching machine with automatic lifting and transporting platform

A transport platform, saddle stitching technology, applied in book binding, transportation and packaging, conveyors, etc., can solve problems such as low binding efficiency and waste of resources, and achieve the effect of improving binding efficiency, ensuring smoothness, and avoiding bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

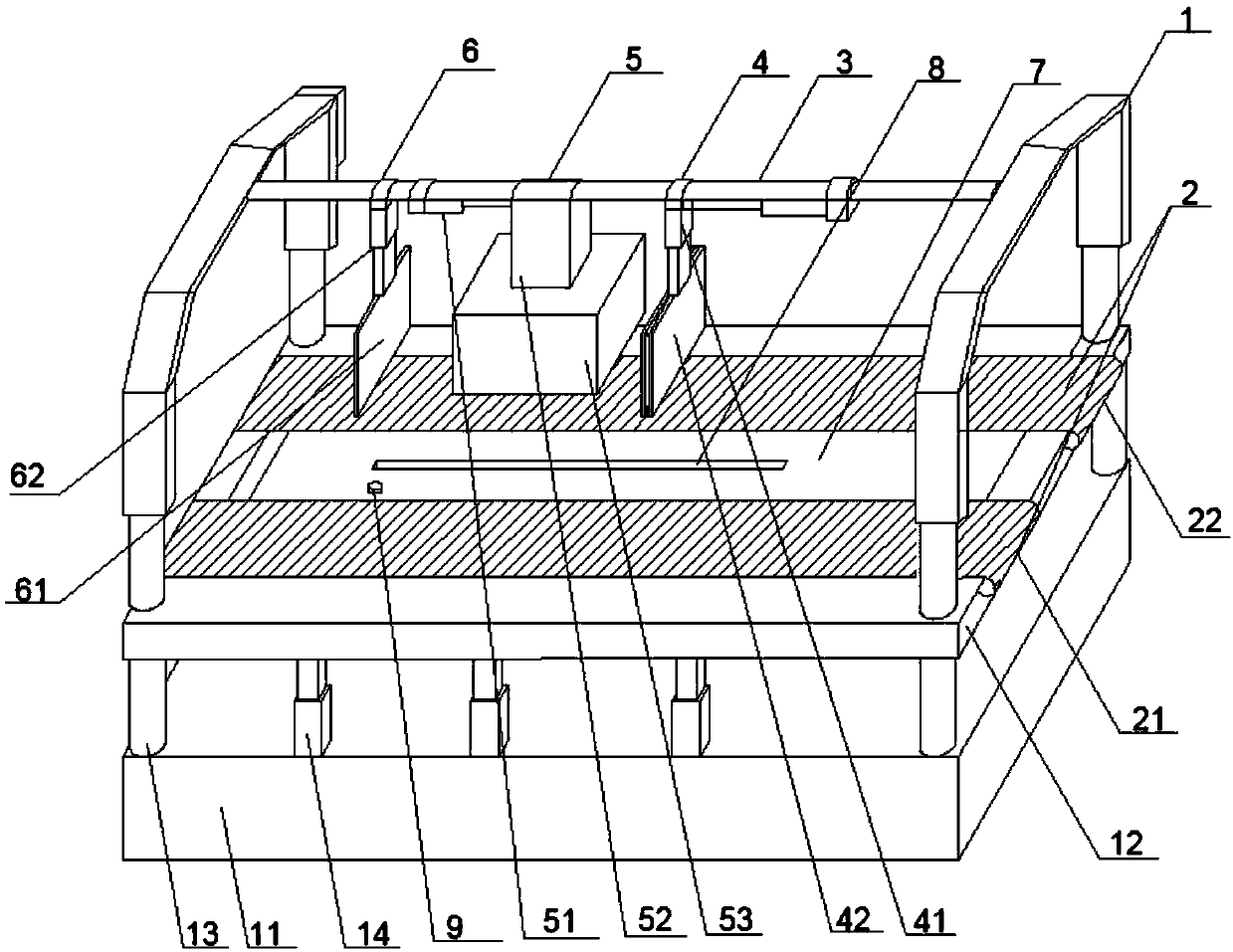

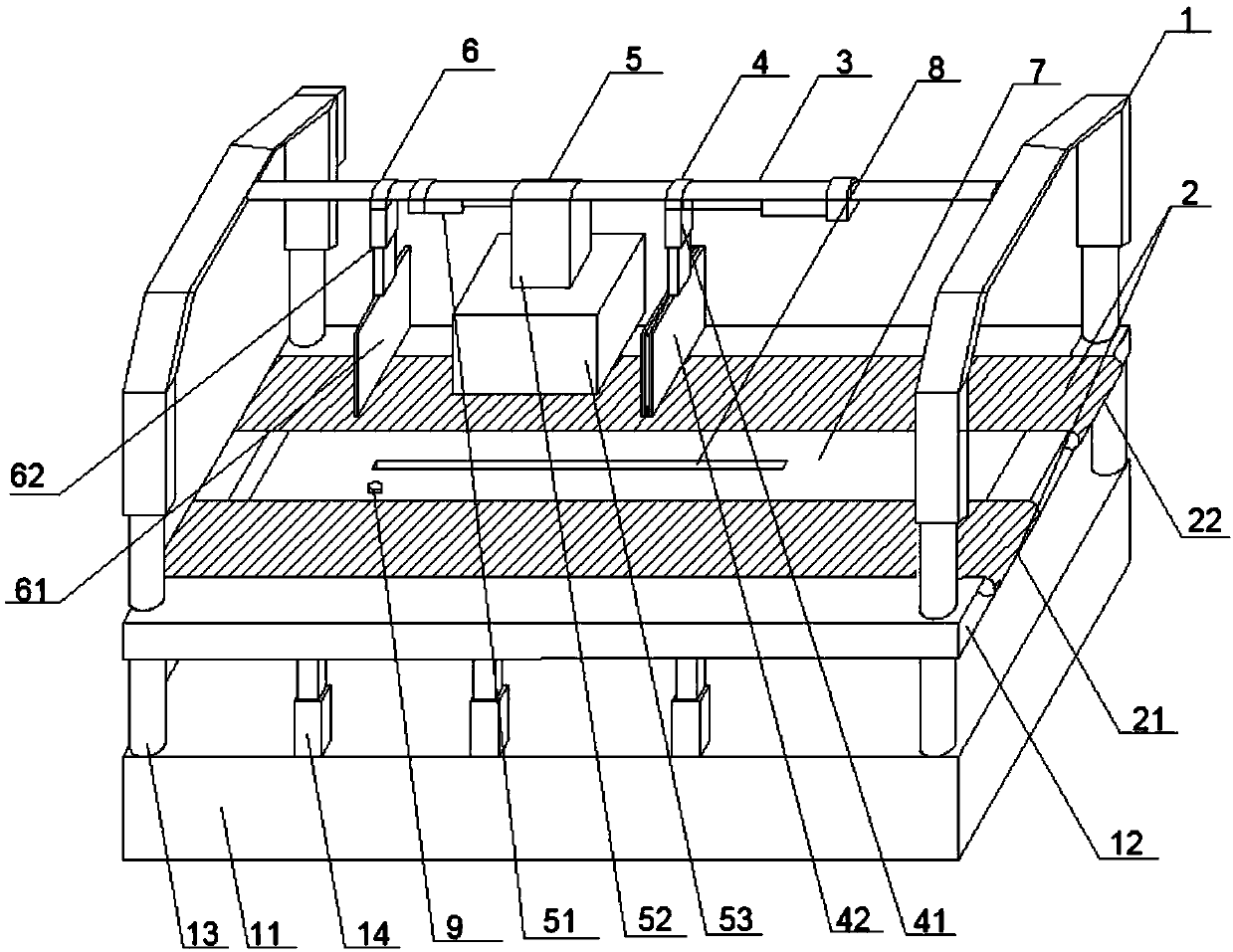

[0038] A fully automatic saddle stitching machine with an automatic lifting transport platform, comprising a base 11, a frame 1 arranged on the base 11, a binding transport platform 12 arranged on the frame 1, and a binding structure, the lower end of the frame 1 is provided with a vertical Sliding shaft 13, binding transport platform 12 is sleeved on the vertical sliding shaft 13, and a cylinder 14 consistent with the direction of the vertical sliding shaft 13 is provided between the binding transport platform 12 and the base 11; the binding transport platform is provided with a transport belt 2 , the conveyor belt 2 includes a first conveyor belt 21 and a second conveyor belt 22 parallel to each other, a gap is provided between the first conveyor belt 21 and the second conveyor belt 22, and a supporting platform 7 is provided on the lower side of the conveyor belt 2, and the gap corresponds to The upper surface of the support platform is provided with a groove 8; the conveyor...

Embodiment 2

[0040] Further, further, the top of the frame 1 is provided with a sliding shaft 3, the frame 1 is provided with a limiting structure 6, and the sliding shaft 3 is provided with a measurement positioning structure 4 and a binding structure 5; wherein, the limiting structure 6 is used to block Binding the book, the lower side of the limit structure is provided with a book detection structure 9, and the measuring and positioning structure 4 is used to detect the length of the book and cooperate with the limit structure to limit the position of the book;

[0041] The fully automatic saddle stitching machine also includes a control structure, which is used to adjust the positions of the binding structure and the measurement and positioning structure according to the situation of the book detected by the measurement and positioning structure.

Embodiment 3

[0043] Further, the limit structure 6 includes a limit baffle 61 and a first cylinder 62 connected to the limit baffle, the first cylinder 62 is fixedly connected to the frame 1 or the sliding shaft 3, and the detection structure 9 in this book is an infrared sensor , the infrared sensor is arranged on the supporting platform at the lower side of the limiting structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com