A timely pressure yielding device capable of compensating large deformation of roadway and its anchoring method

An anchoring method and large deformation technology, which can be used in the installation of bolts, earthwork drilling, mining equipment, etc., can solve the problems of high and uneconomical composite support, complicated construction procedures, and strength effects, and achieve low comprehensive support costs. , The effect of less assembly parts and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

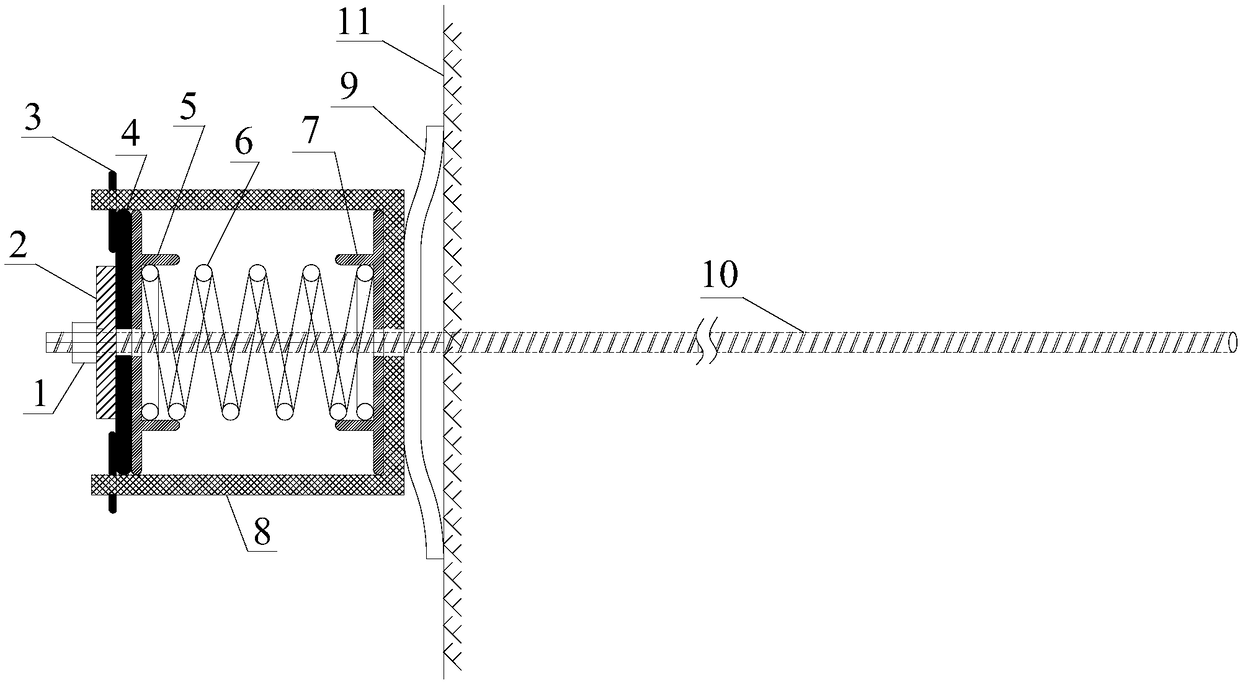

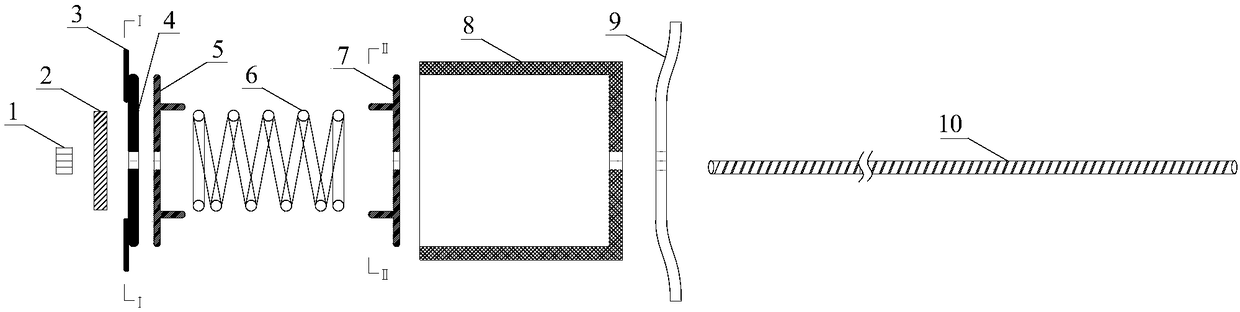

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

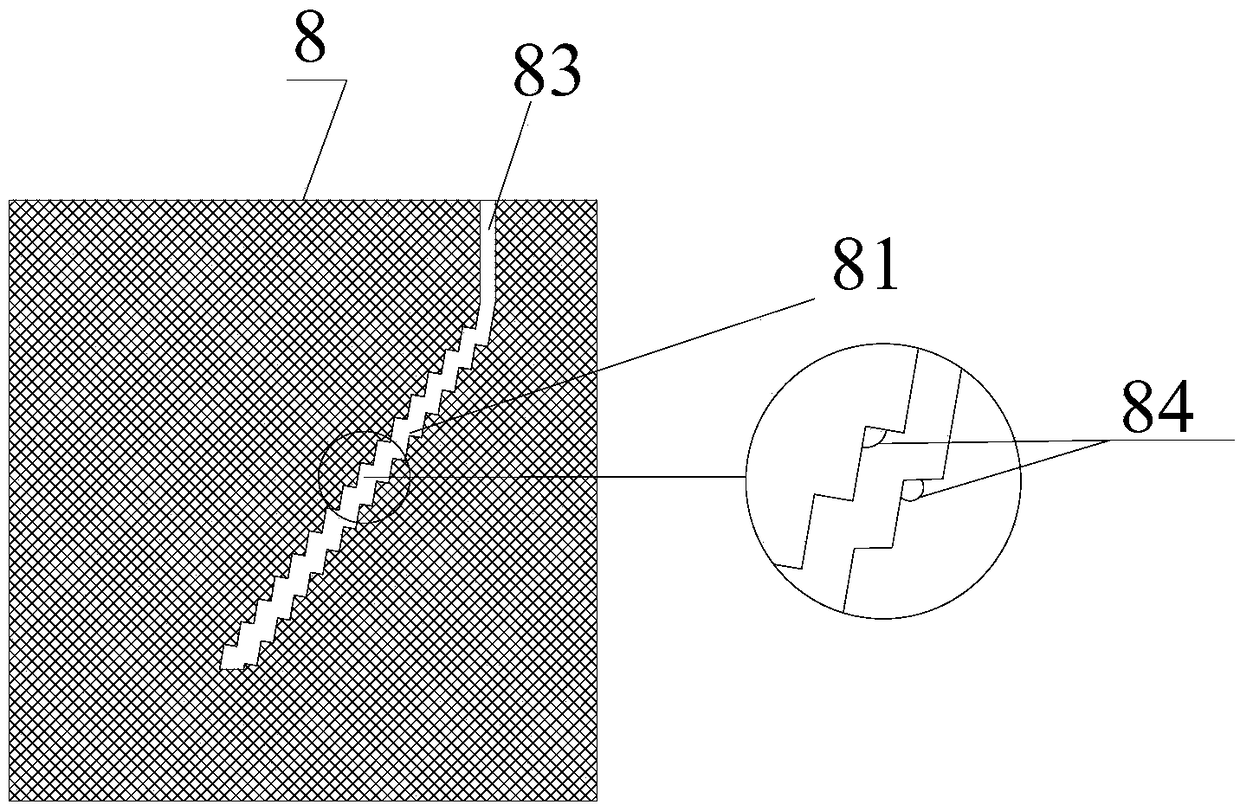

[0028] see Figure 1-4 , a timely yielding device capable of compensating for large deformations in the roadway, including a nut 1, a backing plate 2, a guide rod 3, a steering chassis 4, a second positioning ring 5, a high-strength spring 6, a first positioning ring 7, an annular cylinder 8, Tray 9, bolt body 10, wherein, 11 is surrounding rock wall of roadway. The tray 9 , the annular cylinder 8 , the steering chassis 4 and the nut 1 are in turn sleeved on the anchor body 10 along the axial direction of the anchor body 10 .

[0029] In this embodiment, the high-strength spring is an industrial high-strength and high-density compression spring made of spring steel, with an outer diameter of 80-100 mm and a steel wire diameter of 8 mm.

[0030] 6 sets of high-strength springs are arranged on the anchor rod body and are located between the steering chassis 4 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com