A fully mechanized mining hydraulic support forward moving connector

A technology of hydraulic supports and connectors, which is applied in mine roof supports, mining equipment, earthwork drilling and mining, etc. It can solve problems such as large loads, affecting the support and protection of mining working faces, and the inability to realize the axial transmission of connectors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

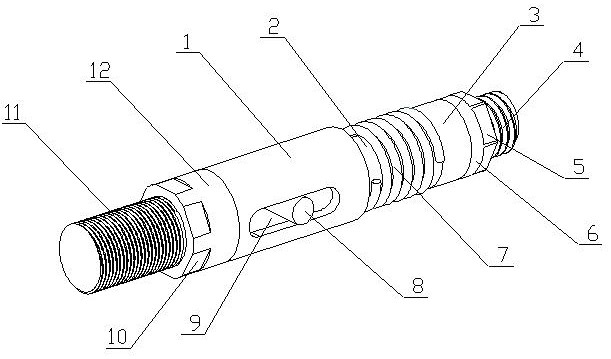

[0016] A fully-mechanized mining hydraulic support forward-moving connector of the present invention is realized in the following way: a fully-mechanized mining hydraulic support forward-moving connector of the present invention consists of a main cylinder (1), a transmission rod (2), a limit sleeve (3), a main Connecting stud (4), main six-sided fixing table (5), universal connecting sleeve (6), tension spring (7), sliding pin (8), sliding groove (9), auxiliary six-sided fixing table (10 ), an auxiliary connecting stud (11) and a rotary connecting sleeve (12), the main body cylinder (1) is provided with a sliding groove (9), the outside of the main body cylinder (1) is threaded, and the transmission rod (2 ) one end is placed in the main cylinder (1), and the other end passes through one end of the main cylinder (1), the other end of the transmission rod (2) is threaded, and one end of the sliding pin (8) is placed on the transmission rod (2) place the other end in the slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com