Control method of antifreeze system and antifreeze system

A control method and antifreeze system technology, applied in heating systems, refrigerators, heating methods, etc., can solve problems such as inability to obtain antifreeze effects, energy consumption, and affecting user heating experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

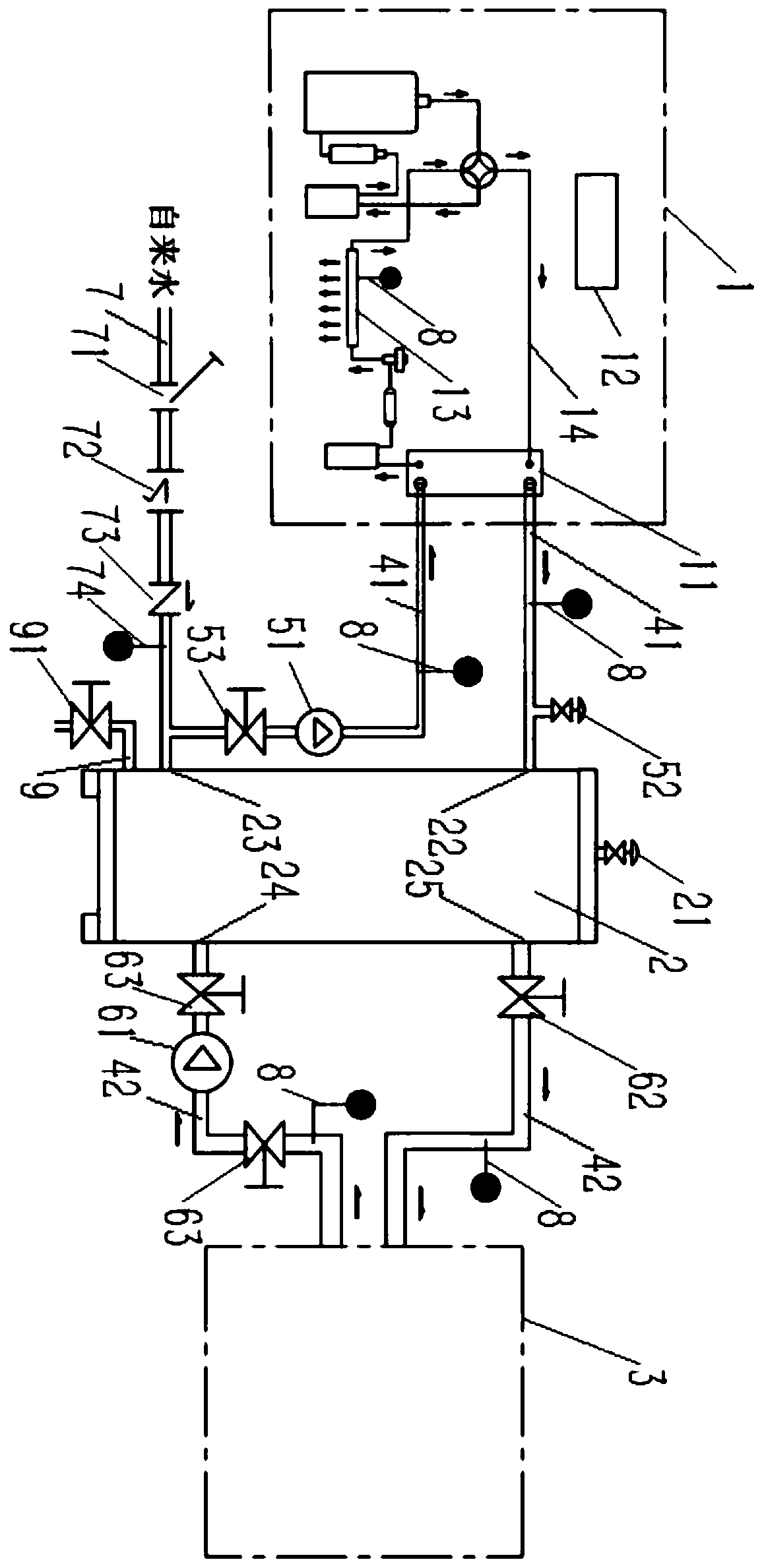

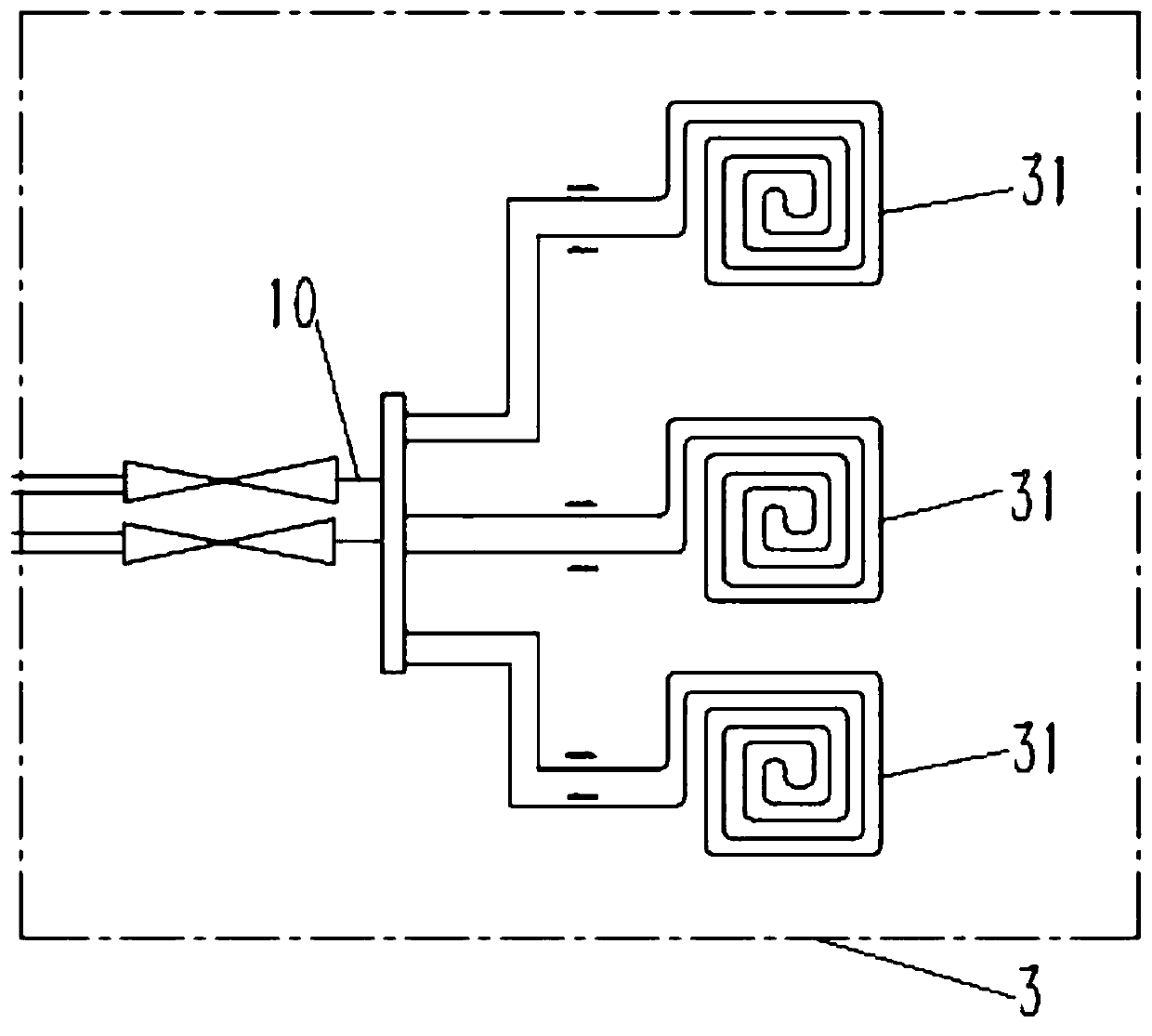

[0101] This embodiment provides an antifreeze system, such as figure 1 As shown, it includes a host 1, an incubator 2, and a heating device 3.

[0102] The main engine 1 includes a compressor, a condenser 11 , and an evaporator 13 sequentially connected through a fourth pipeline 14 , and the evaporator 13 and the compressor are connected through the fourth pipeline 14 to form a circulation loop for refrigerant circulation. That is, the cooling or heating system of the air conditioning system. The refrigerant turns from gas to liquid in the condenser and releases heat to the outside. This antifreeze system uses the heat released by the refrigerant in the condenser to heat the medium.

[0103] The evaporator 13 is provided with a first temperature detector 8 for obtaining the ambient temperature T0; the condenser 11 is preferably a plate heat exchanger, and the refrigerant releases heat through the condenser 11 to heat the medium in the condenser 11 to make the medium temperature...

Embodiment 2

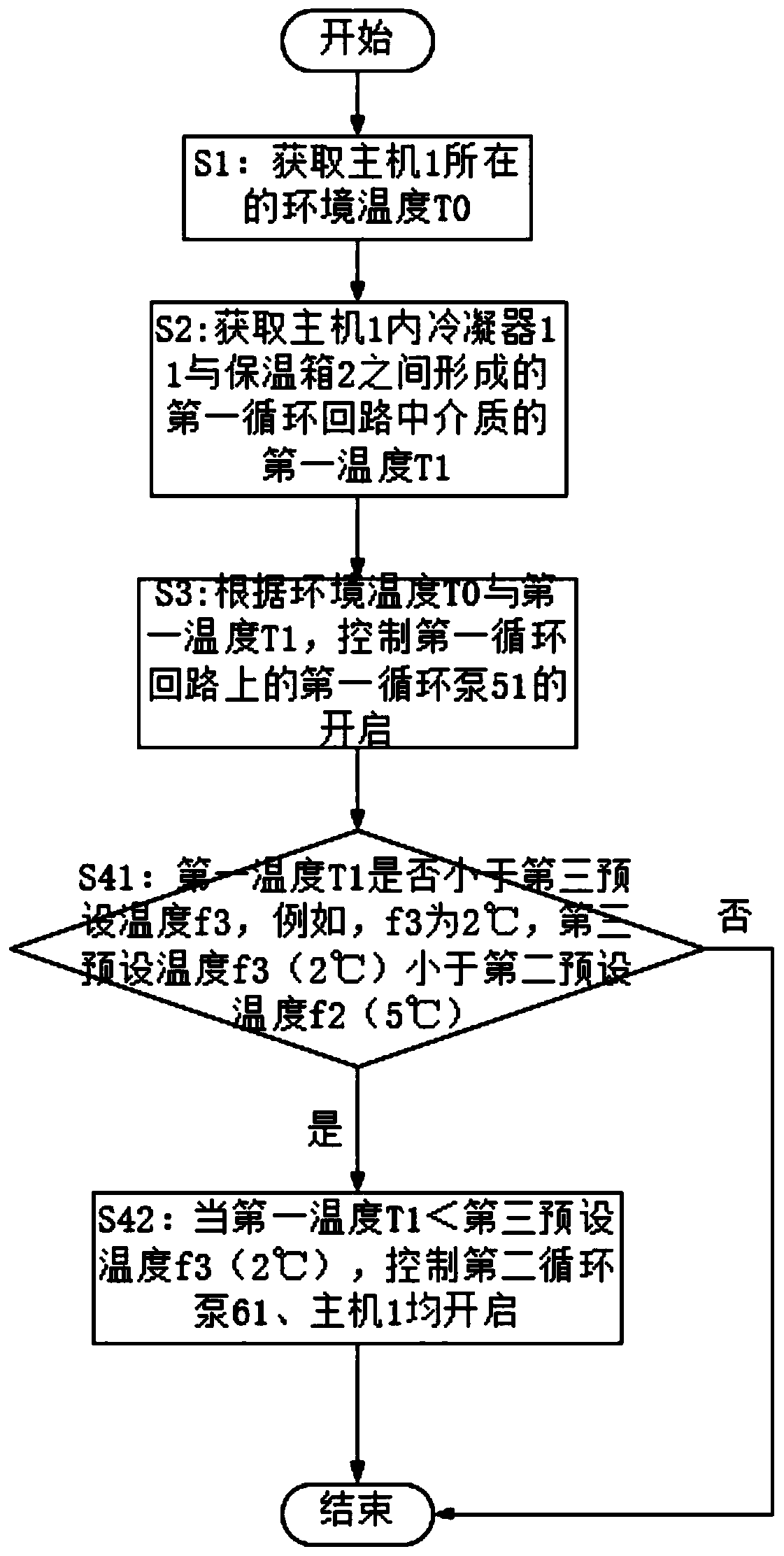

[0116] This embodiment provides a control method based on the antifreeze system provided in Embodiment 1, such as image 3 shown, including the following steps:

[0117] S1: Obtain the ambient temperature T0 where host 1 is located;

[0118] S2: Obtain the first temperature T1 of the medium in the first circulation loop formed between the condenser 11 in the host 1 and the incubator 2;

[0119] S3: According to the ambient temperature T0 and the first temperature T1, control the opening of the first circulation pump 51 on the first circulation loop. The steps are specifically:

[0120] S31: Determine whether the ambient temperature T0 is lower than the first preset temperature f1, for example, f1 is 3°C;

[0121] S32: When the ambient temperature T0 is lower than the first preset temperature f1 (3°C); then judge whether the first temperature T1 is lower than the second preset temperature f2, for example, f2 is 5°C;

[0122] S33: When the first temperature T1 is lower than ...

Embodiment 3

[0127] This embodiment provides a control method for an antifreeze system, such as Figure 4 As shown, compared with the control method of the antifreeze system provided in Example 2, the difference is that the control method of the antifreeze system can also judge whether to turn on the antifreeze system according to the third temperature T3 of the medium in the third pipeline.

[0128] S1: Obtain the ambient temperature T0 where host 1 is located;

[0129] S2: Obtain the third temperature T3 of the medium in the third pipeline 7 for supplementing the required medium in the first circulation loop;

[0130] S3: According to the ambient temperature T0 and the third temperature T3, control the opening of the first circulation pump 51 on the first circulation loop. The steps are specifically:

[0131] S31: judging whether the ambient temperature T0 is lower than the first preset temperature f1 (3° C.);

[0132] S32: When the ambient temperature T0 is lower than the first prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com