Temperature adaptive high brightness led direct type LCD backlight module

A backlight module, high-brightness technology, applied in the direction of optics, light source, electric light source, etc., can solve the problems of reducing the service life of the LCD screen, burning out the LCD screen, increasing the brightness of the LCD screen, etc., to meet the requirements of high-brightness display and extended use field, the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

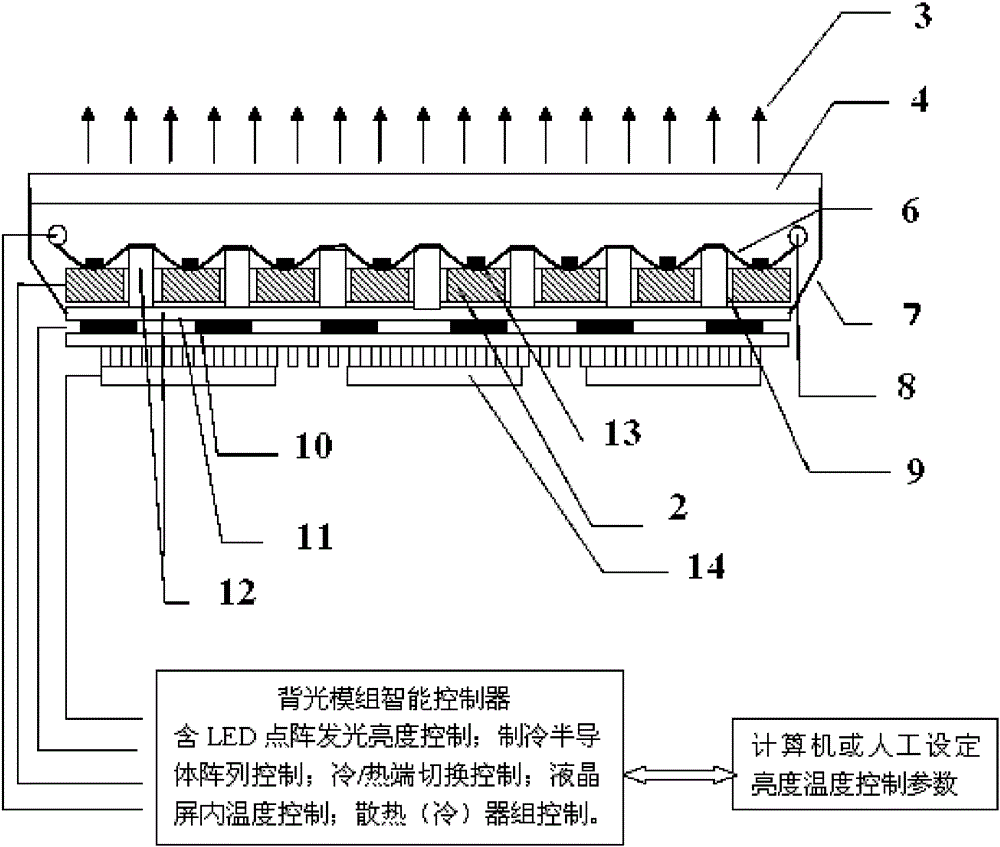

[0028] Embodiment 1: temperature self-adaptive high-brightness LED direct type liquid crystal backlight module 52-inch liquid crystal backlight module, and refit a general-purpose 52-inch liquid crystal screen with the novel LED backlight module of the present invention, greatly improve the brightness of the liquid crystal screen, make the liquid crystal The temperature of the whole screen (including the backlight module) is controlled within the set range.

[0029] refer to figure 2 : The 52-inch general-purpose LCD screen used in this embodiment is: Samsung 52-inch LCD screen LTA520HB13, the factory-packed LCD backlight module is a CCFL lamp backlight module, the brightness is 450 cd / ㎡, and the working temperature is 0~50°C.

[0030] The temperature self-adaptive high-brightness LED direct type LCD backlight module is used to replace the original CCFL backlight module with a 52-inch LCD backlight module. The structure of the new backlight module is as follows: figure 2A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com