Pressing device and method for trace concrete real pore solution

A pore solution and concrete technology, which is applied in the field of pressing devices for micro-concrete real pore solution, can solve the problems of low safety and poor sealing, and achieve the effect of simple processing and production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

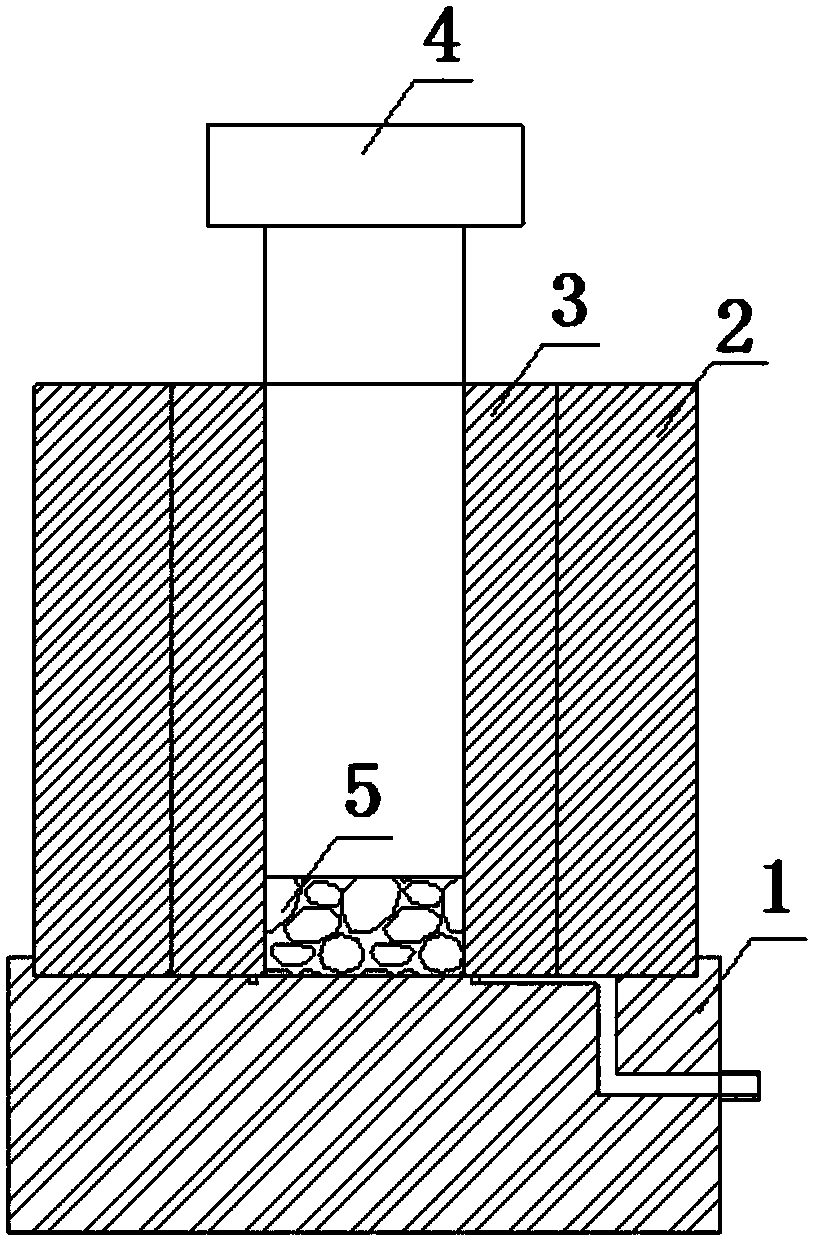

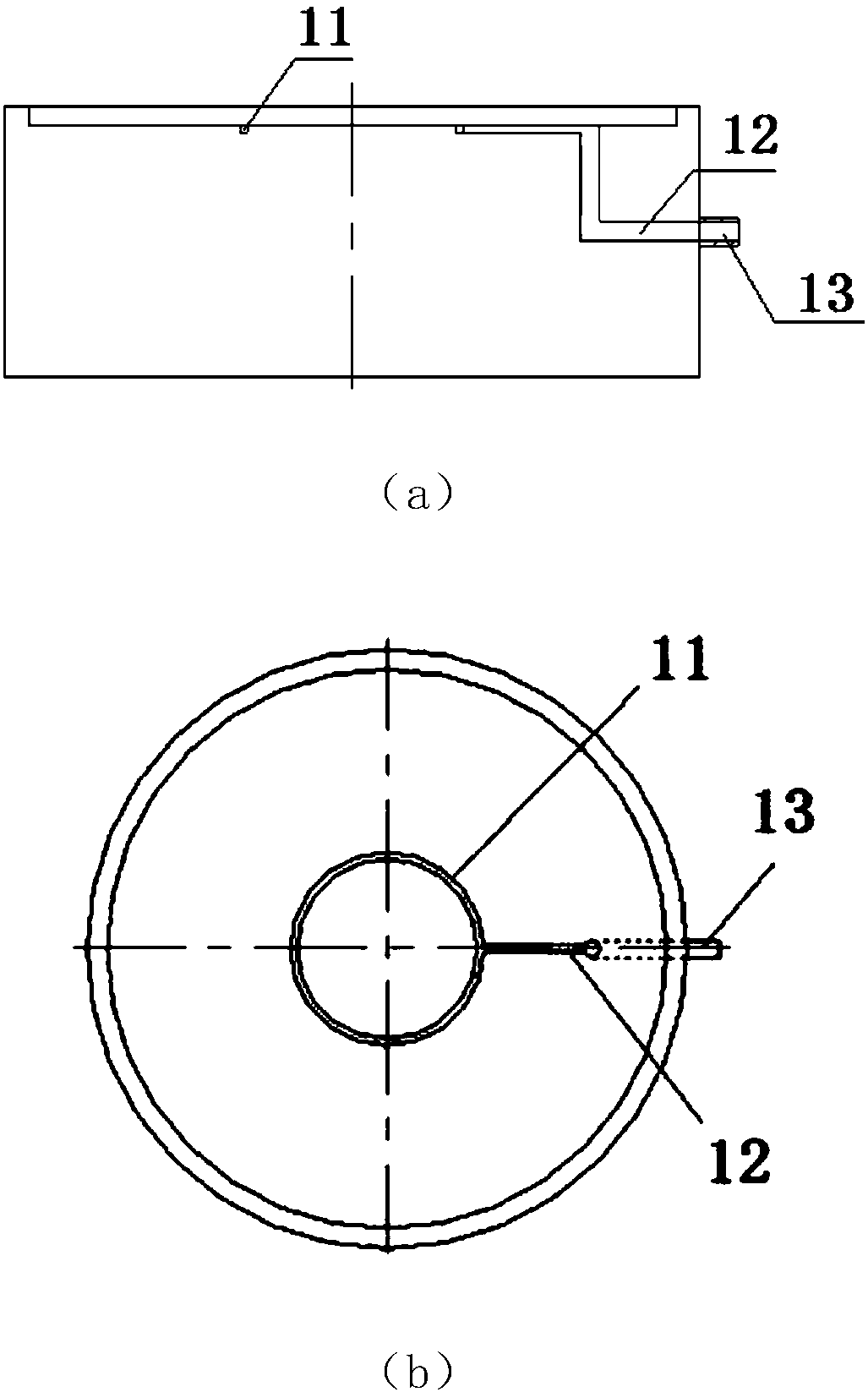

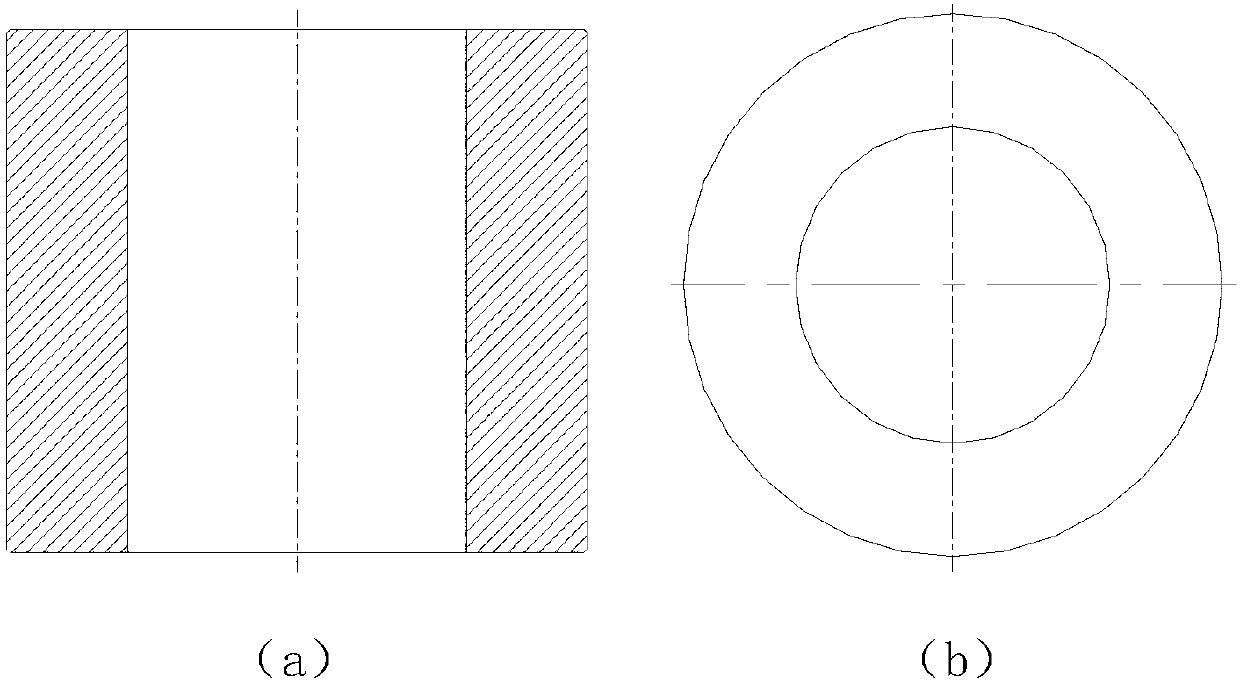

[0029] see Figure 1 to Figure 5 , the present embodiment provides a squeeze device for a trace amount of concrete real pore solution, including a base 1, the base 1 has a raised edge, and an outer sleeve 2 and an inner sleeve 3 concentrically arranged on the base 1 are installed, wherein, The outer sleeve 2 is in contact with the raised edge of the base 1, the inner sleeve 3 has a pressure-conducting piston 4 in the center, and a circle of circular grooves 11 (circular concave grooves 11) for collecting pore solutions are arranged on the upper surface of the base 1. The specific position of the groove 11 is close to the inner diameter of the bottom surface of the inner sleeve 3), and there is a hole solution outlet pipe 12 leading to the side of the base 1 on the side of the circular groove 11.

[0030] In this embodiment, the base 1, the inner sleeve 3 and the piston 4 are all made of Cr12MoV die steel, and heat treated and quenched to 58-62HRC.

[0031] Outer sleeve 2 adop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com