Slurry multi-stage rotation comprehensive measurement method and device

A measuring device and comprehensive measurement technology, which is applied in the direction of measuring device, specific gravity measurement, test sample preparation, etc., can solve the problems of fast wear of density meters, short service life, difficult maintenance and other problems, and achieve convenient maintenance and replacement, saving energy The effect of consumption and avoiding wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

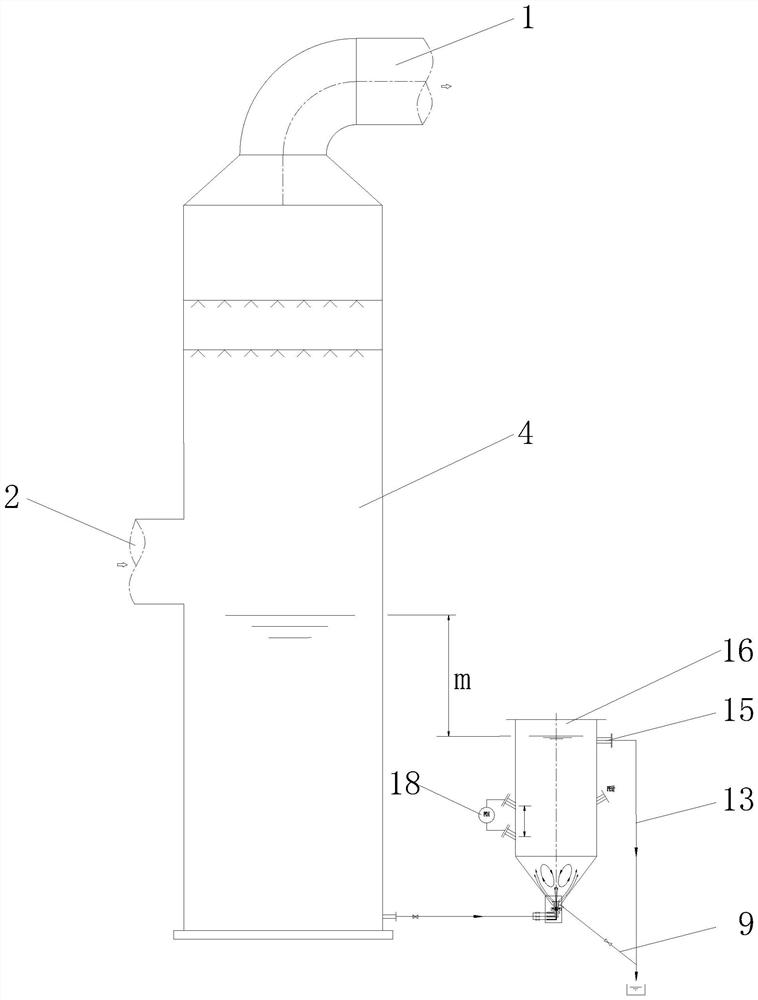

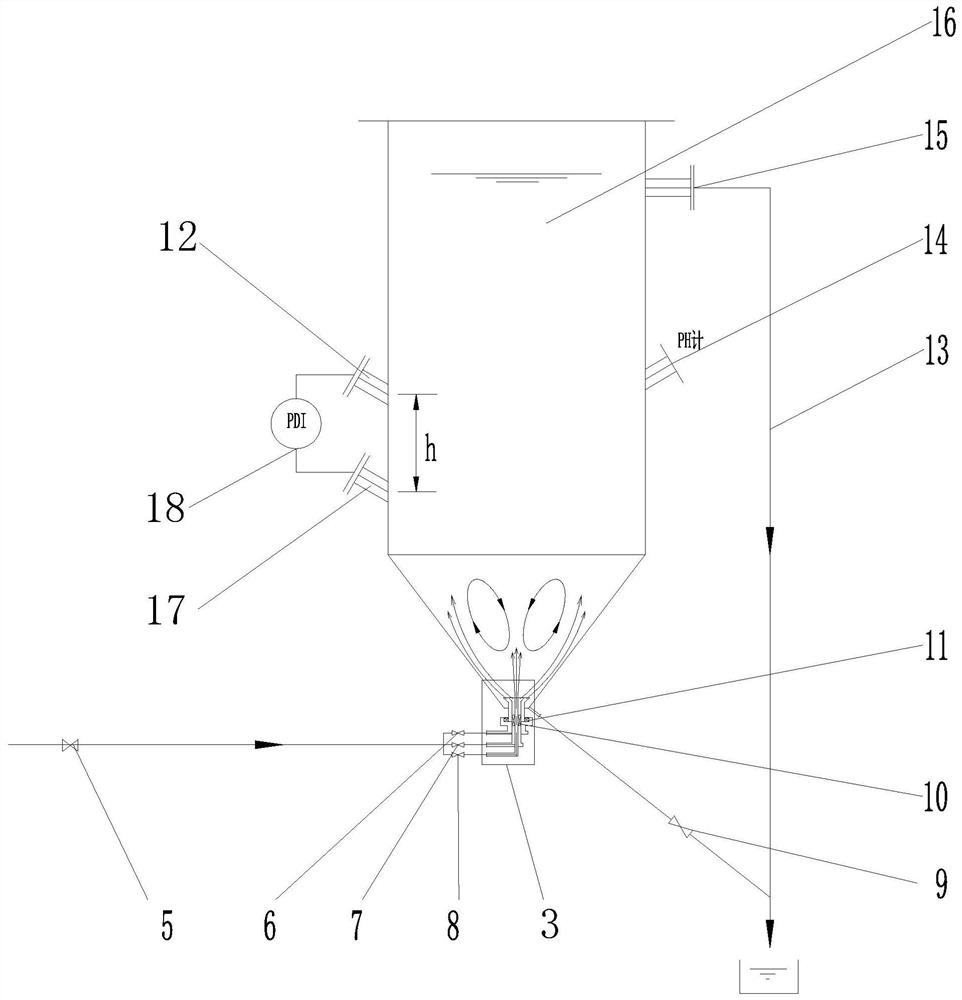

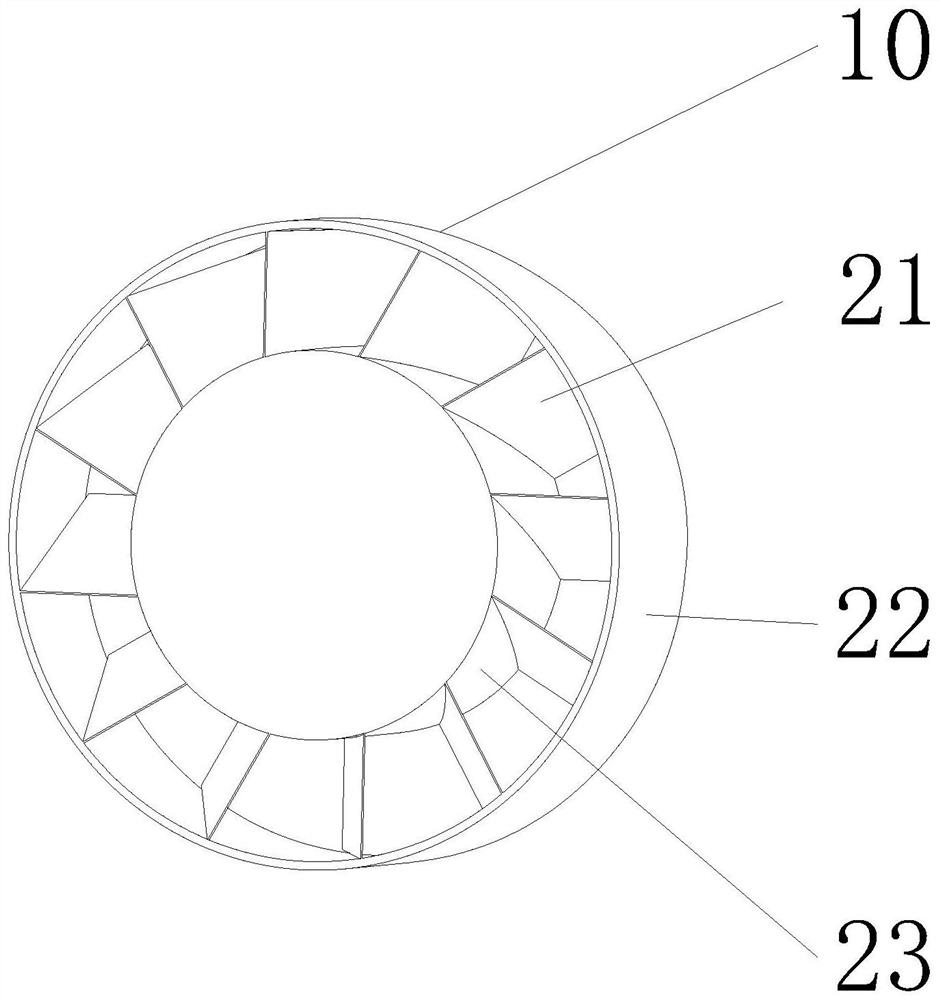

[0028] Embodiment 1 of the present invention: a multi-stage rotary comprehensive measuring device for slurry, comprising a desulfurization tower 4, a first valve 5, a measuring device 16 connected to the desulfurization tower 4 through the first valve 5, a first branch pipe 8, and a second branch pipe 7. The third branch pipe 6 and the nested spraying device 3, the desulfurization tower inlet 2 is provided on the side wall of the desulfurization tower 4, the desulfurization tower outlet 1 is arranged in the desulfurization tower 4, and the first valve 5 is connected with the desulfurization tower 4 , the first branch pipe 8, the second branch pipe 7 and the third branch pipe 6 are all connected with the first valve 5, and a slurry delivery valve is installed on the first branch pipe 8, the second branch pipe 7 and the third branch pipe 6, The first branch pipe 8 , the second branch pipe 7 and the third branch pipe 6 are connected to the nested shotcrete device, and the nested s...

Embodiment 2

[0029] Embodiment 2 of the present invention: a slurry multi-stage rotary comprehensive measuring device, comprising a desulfurization tower 4, a first valve 5, a measuring device 16 connected to the desulfurization tower 4 through the first valve 5, a first branch pipe 8, and a second branch pipe 7. The third branch pipe 6 and the nested spraying device 3, the desulfurization tower inlet 2 is provided on the side wall of the desulfurization tower 4, the desulfurization tower outlet 1 is arranged in the desulfurization tower 4, and the first valve 5 is connected with the desulfurization tower 4 , the first branch pipe 8, the second branch pipe 7 and the third branch pipe 6 are all connected with the first valve 5, and a slurry delivery valve is installed on the first branch pipe 8, the second branch pipe 7 and the third branch pipe 6, The first branch pipe 8 , the second branch pipe 7 and the third branch pipe 6 are connected to the nested shotcrete device 3 , and the nested sh...

Embodiment 3

[0030]Embodiment 3 of the present invention: a slurry multi-stage rotary comprehensive measuring device, comprising a desulfurization tower 4, a first valve 5, a measuring device 16 connected to the desulfurization tower 4 through the first valve 5, a first branch pipe 8, and a second branch pipe 7. The third branch pipe 6 and the nested spraying device 3, the desulfurization tower inlet 2 is provided on the side wall of the desulfurization tower 4, the desulfurization tower outlet 1 is arranged in the desulfurization tower 4, and the first valve 5 is connected with the desulfurization tower 4 , the first branch pipe 8, the second branch pipe 7 and the third branch pipe 6 are all connected with the first valve 5, and a slurry delivery valve is installed on the first branch pipe 8, the second branch pipe 7 and the third branch pipe 6, The first branch pipe 8 , the second branch pipe 7 and the third branch pipe 6 are connected to the nested shotcrete device 3 , and the nested sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com