Method and device for measuring grain density

A technology of density measurement and weight measurement device, applied in the field of measurement, can solve the problems of low accuracy and difficult application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

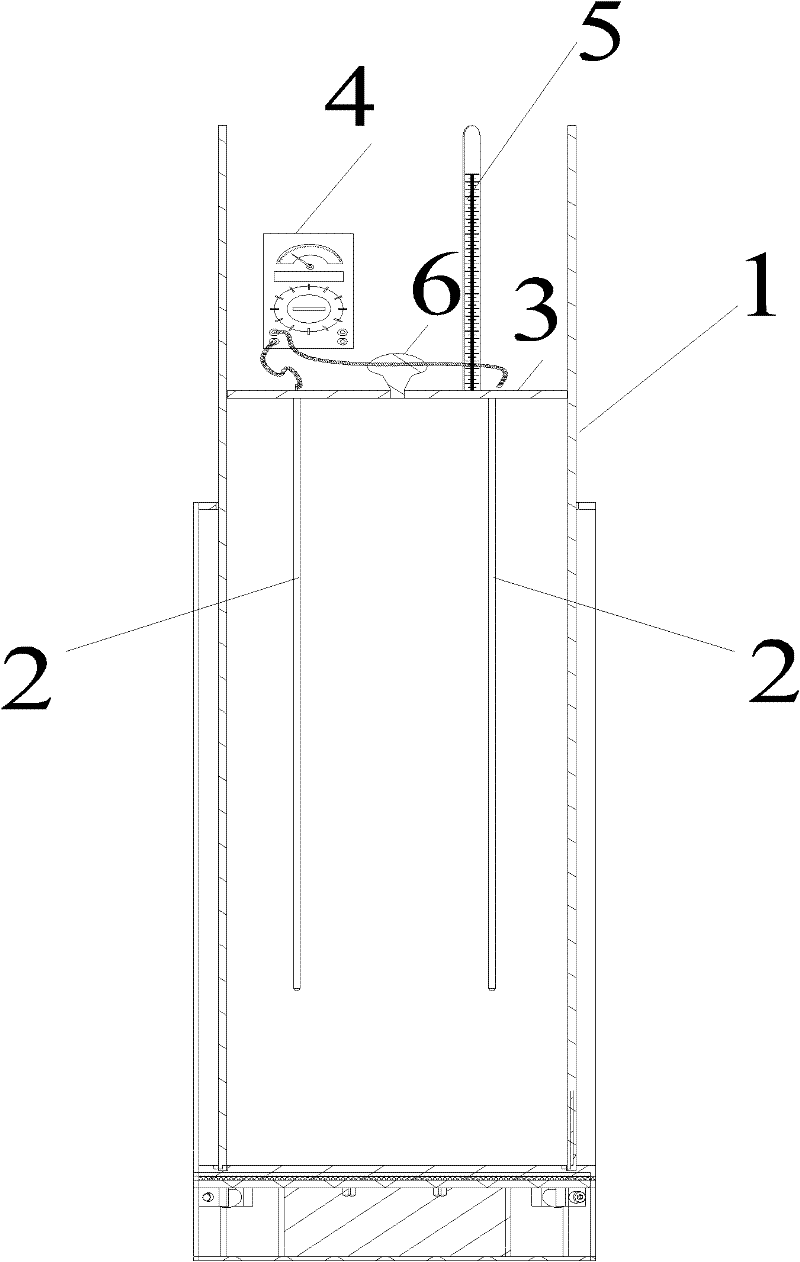

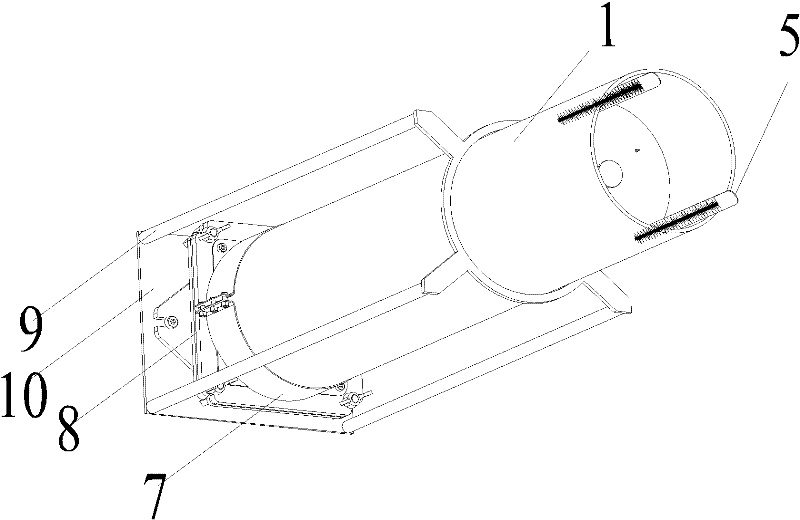

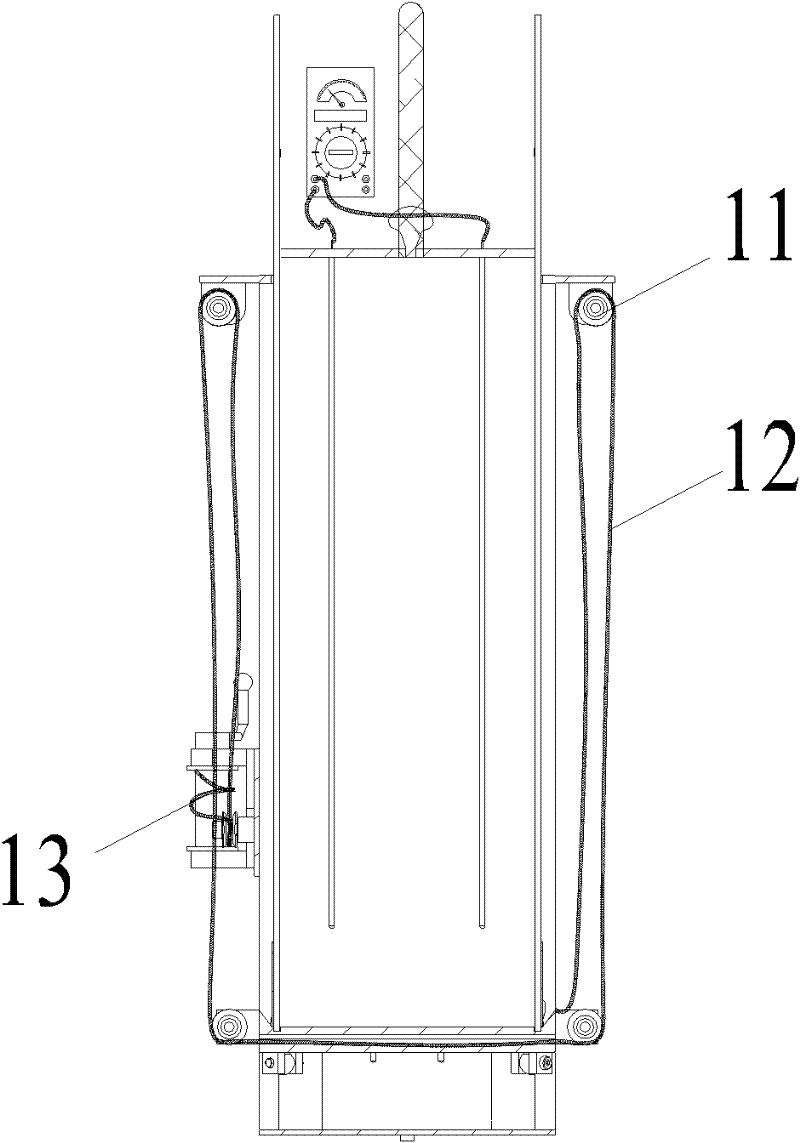

[0018] like figure 1 , 2 , 3 and 4, the embodiment of the present invention provides a grain density measuring device, which can be used to test the density of grain piles, including: a container tube 1 (1.4 meters high, 30 centimeters in diameter) for adorning grain samples, a cover 3 , a capacitance measuring instrument 4, an electronic scale (not shown in the figure), a vibrator (not shown in the figure) and a lifting mechanism for lifting the height of the container tube 1 . Wherein, the cover 3 is an insulating disc with a thickness of 2 cm, and its diameter is slightly smaller than the inner diameter of the outer cylinder. Two hard metal straight wires as electrodes are installed on the cover, with a length of 82 cm, placed in parallel, and connected to the capacitance measuring instrument. 4 connections. The hard metal straight wires should be fixed on the cover, and the two hard metal straight wires can still remain parallel when inserted into the grain pile. Two sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com