Heat-insulating kettle

A technology for boiling kettles and kettle body, which is applied in the field of thermal insulation boiling kettles. It can solve the problems of not being able to prevent the transmission of heat sources from increasing the temperature and energy consumption, and the poor thermal insulation capacity of boiling kettles. It achieves the effects of preventing the transmission of heat sources, novel structure, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

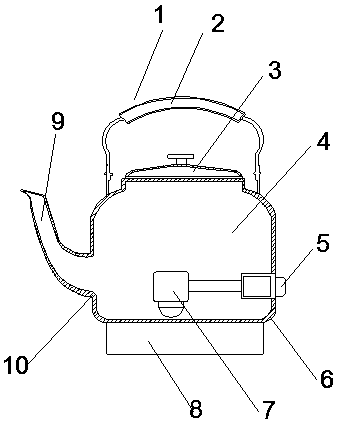

[0016] Such as figure 1 As shown, the present invention provides an insulated kettle, comprising a kettle body 1, a kettle handle 2, a kettle lid 3, a built-in cavity 4, a power jack 5, a kettle body 6, a heater 7, a base 8, a spout 9 and a vacuum The interlayer 10, the top of the pot body 1 is provided with a pot cover 3, the bottom of the pot cover 3 is provided with a pot body 6, the bottom of the pot body 6 is equipped with a base 8, the top of the pot body 6 is equipped with a pot handle 2, and the pot body One end of the kettle body 6 is provided with a spout 9, the inside of the kettle body 6, the kettle spout 9 and the kettle lid 3 are all provided with a vacuum interlayer 10, the other end of the kettle body 6 is equipped with a power jack 5, and the inner side of the kettle body 6 is provided with an inner The built-in cavity 4 is equipped with a heater 7 inside the built-in cavity 4 .

[0017] The pot handle 2 is movably connected to the top of the pot body 6, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com