A high-temperature flue gas dust removal cooling device

A cooling device and high-temperature flue gas technology, which is applied in the field of flue gas treatment, can solve the problems of difficult dust collection and low dust adsorption, and achieve the effects of high adsorption, good adsorption, and reduced collection difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further detailed explanation through specific implementation mode below:

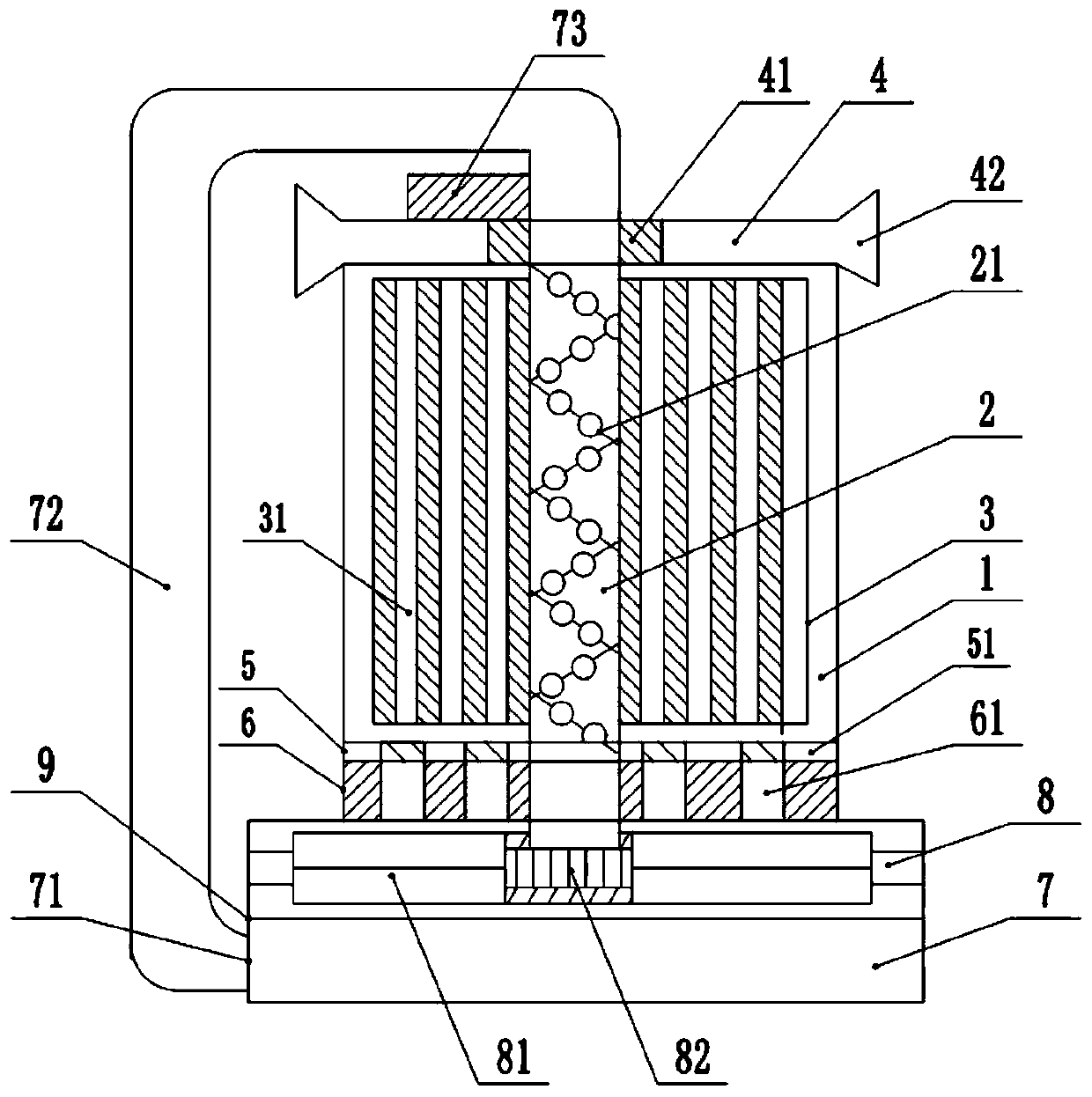

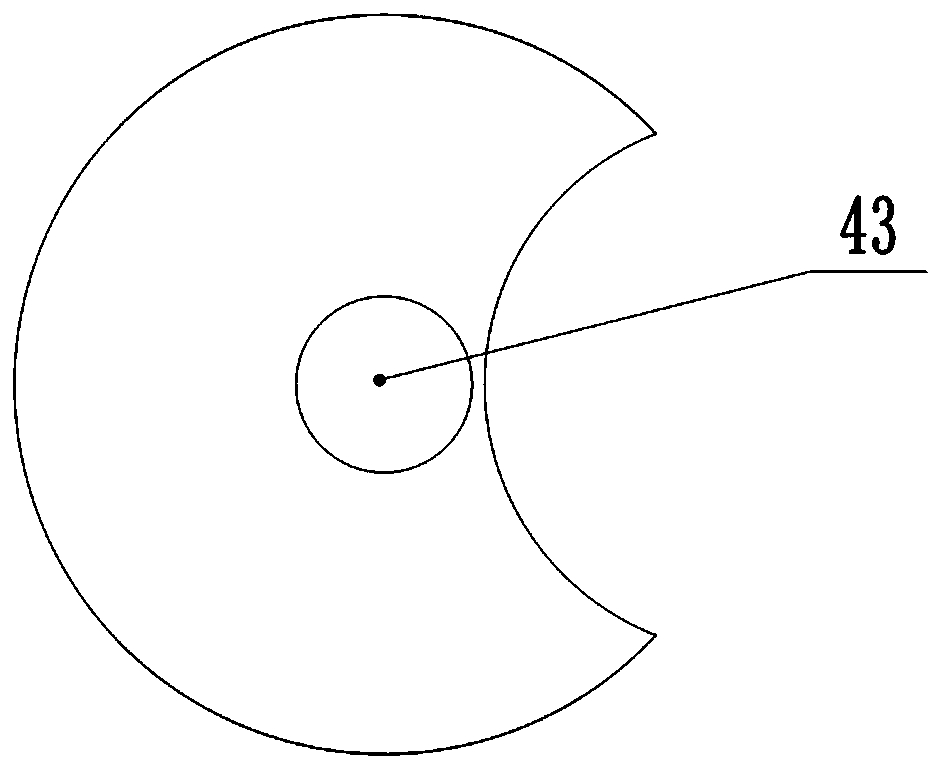

[0019] The reference signs in the drawings of the description include: housing 1, rotating shaft 2, spray hole 21, dust removal blade 3, groove 31, air inlet pipe 4, one-way rotary air intake valve 41, air inlet 42, threaded hole 43 , Interception part 5, through hole 51, matching part 6, air outlet hole 61, receiving pool 7, water outlet hole 71, water inlet pipe 72, pressure pump 73, transverse shaft 8, receiving blade group 81, worm gear and worm screw 82, filter layer 9.

[0020] The embodiment is basically as attached figure 1 , 2 Shown: a high-temperature flue gas dust removal cooling device, including a dust removal cooling mechanism and a receiving mechanism. The dust removal cooling mechanism includes a casing 1 and a rotating shaft 2. The bottom of the casing 1 is smoothly arranged. The rotating shaft 2 is located inside the casing 1, and the inside of the rotating shaft 2 is hollow. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com