Induction mechanism, motion device and motion system

A technology of induction part and skateboard mechanism, applied in the field of motion system, can solve the problems of high maintenance cost, strong mechanical vibration, parts damage, etc., to reduce mutual interference and inconsistency, accurate and stable motion control, and reduce production and maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

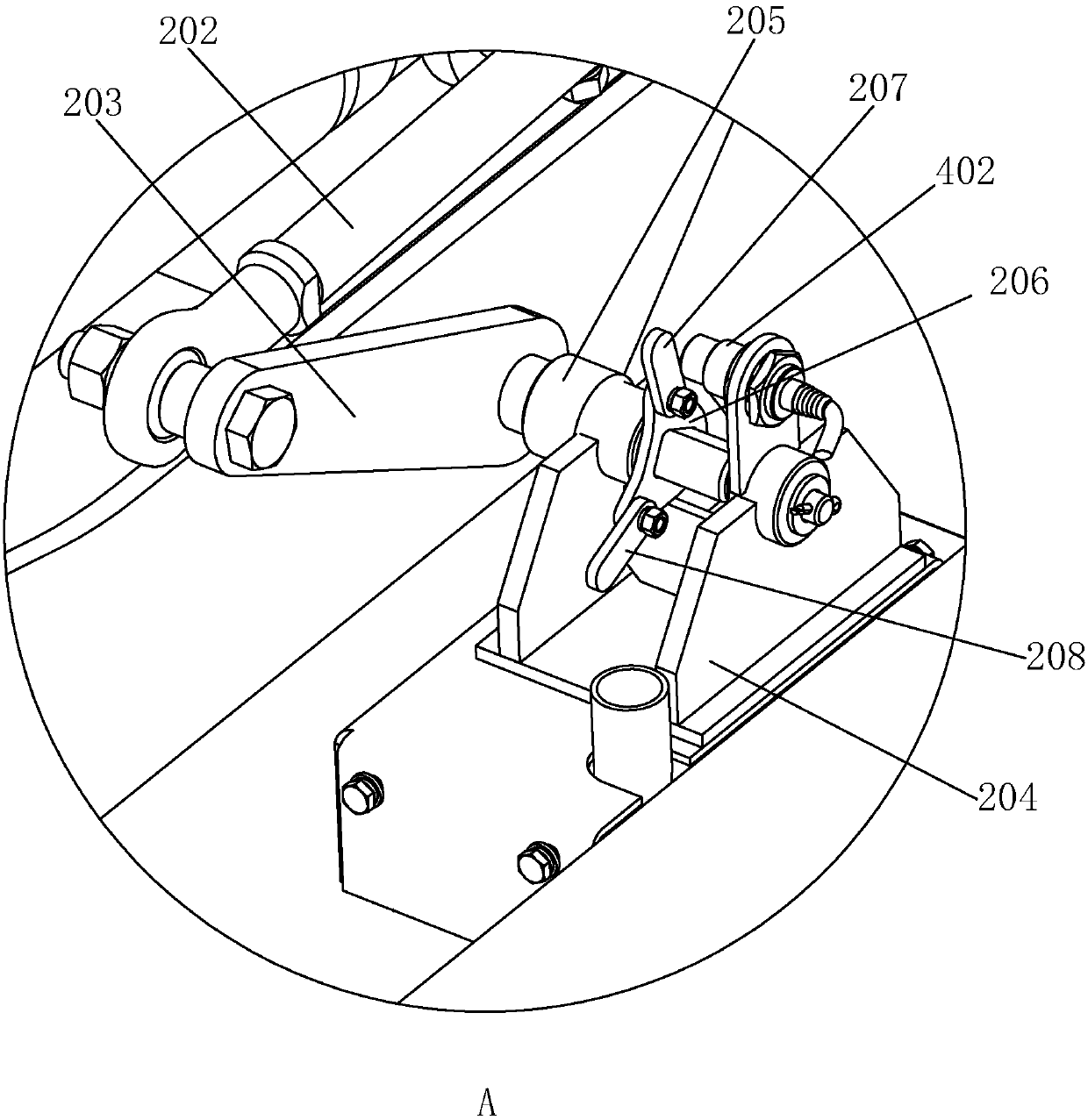

[0040] An induction mechanism, especially a two-position induction mechanism, includes a follower and a first sensor that are connected to an external drive through a connecting piece, the drive moves reciprocatingly, and the follower moves with the drive through the connecting piece. The moving part moves synchronously, the driven part is provided with a sensing part, and the sensing part is provided with a first sensing part and a second sensing part which follow the moving part to move synchronously. When the original moving part moves to two different positions of its reciprocating motion track, The first sensing part and the second sensing part can be sensed by the first sensor respectively.

[0041] When the original moving part reciprocates, the driven part is driven to reciprocate through the transmission of the connecting part, and then the first sensing part and the second sensing part are driven to reciprocate to the sensing end of the first sensor, so that one senso...

Embodiment 2

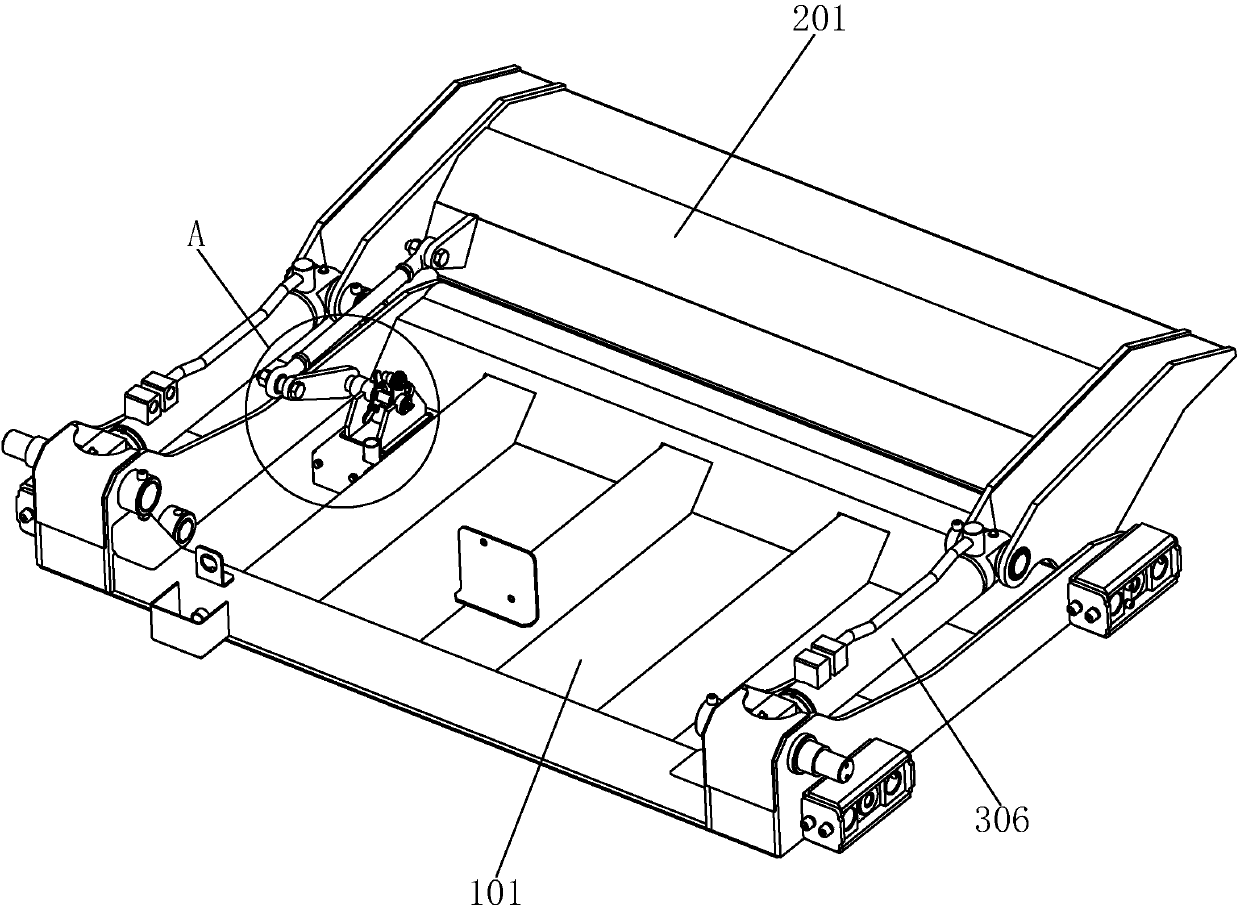

[0050] a movement device such as figure 1 and figure 2 As shown, it includes the scraper mechanism 201 as the driving element, the slider mechanism 101, the power mechanism and the two-position induction mechanism in Embodiment 1, the connecting rod 202 as the connecting piece, the crank 203 as the follower, the scraper mechanism 201 and the The slide mechanism 101 is connected in rotation, and the scraper mechanism 201 is driven by the power mechanism to perform reciprocating opening and scraping movements.

[0051] By using the double-position sensing mechanism in Embodiment 1, it is possible to realize the position sensing of the opening and scraping motion states of the scraper mechanism 201, thereby reducing the number of sensors used, reducing production costs, and making the scraper mechanism 201 The position sensing of the motion state is more accurate and stable, which makes the switching between opening and closing of the scraper mechanism 201 more consistent.

[...

Embodiment 3

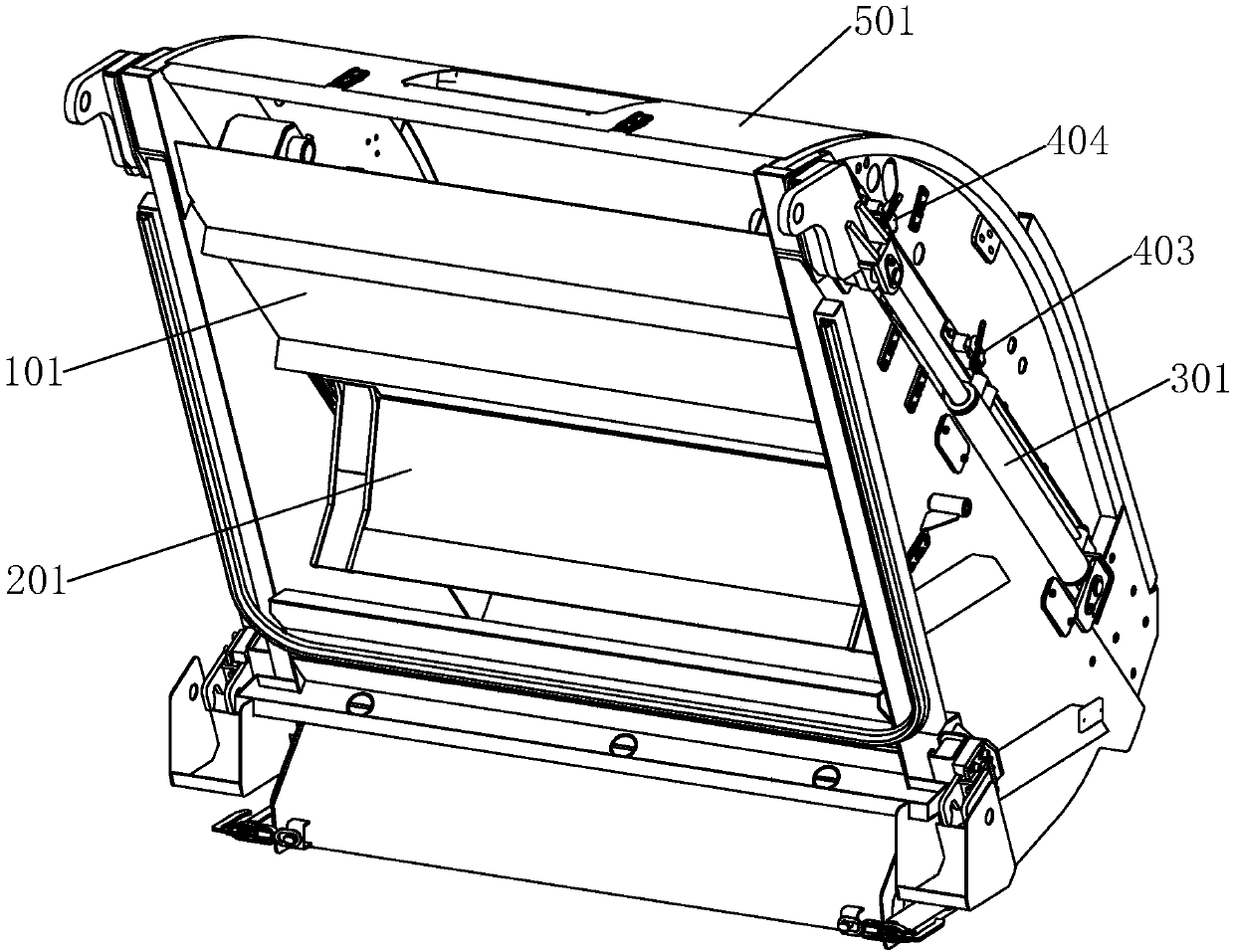

[0057] A filling device for a compressed garbage truck, such as Figures 1 to 3 As shown, it includes a housing 501 mounted on the opening of the garbage truck compartment, the motion device described in Embodiment 2, and a controller 401 for providing control functions of various mechanisms.

[0058] The two sides of the slider mechanism 101 installed in the housing 501 are slidingly connected to the left and right side walls of the housing 501 respectively, and protrude from the left and right side walls of the housing 501. The slider mechanism 101 is driven by the power mechanism to perform a reciprocating sliding motion. The direction is inclined from top to bottom from the front of the garbage truck to the rear.

[0059] Both the second sensor 403 and the third sensor 404 are installed on the same side wall or opposite different side walls of the filler, and are respectively located near the end point of the slide mechanism 101 sliding down and the position close to the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com