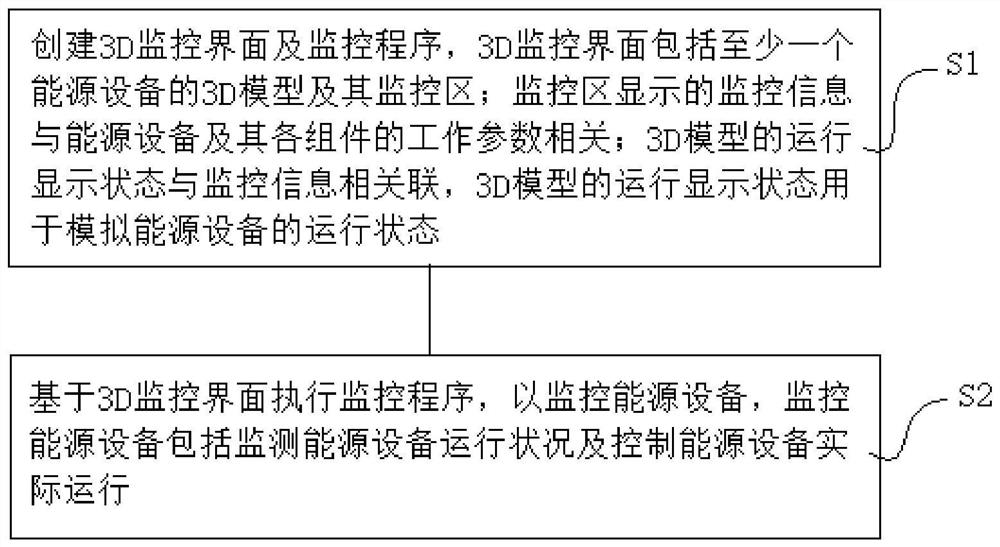

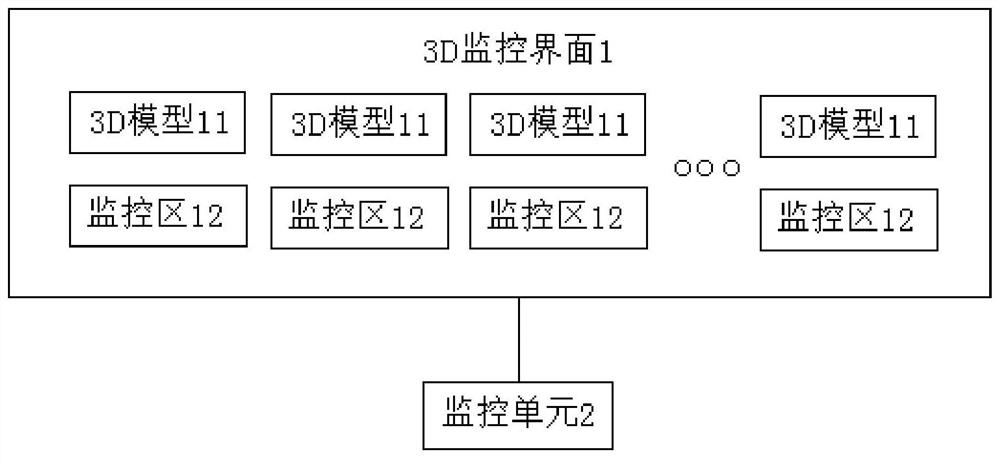

A 3D-based energy equipment monitoring method and system

A device monitoring and 3D technology, applied in 3D modeling, digital output to display equipment, data processing input/output process, etc., to achieve good real-time performance, convenient implementation, good reusability and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] Step1: Use 3D design software (such as SolidWorks) to disassemble and model the fan, and design each component of the fan in turn, including: blades, hubs, main shafts, nacelles and towers, etc., to form multiple component files (such as blade 1.SLDPRT) ;

[0118] Step2: Assemble and merge the components of each fan into an assembly (such as fan.SLDASM), and then export the assembly as a fan model file (such as fan_old.xaml);

[0119] Step3: Optimize the exported fan model file, and use the defined model template to generate an optimized model file (such as fan.xaml);

[0120] Step4: Create an interface of a 3D model, and define the general properties of the interface (such as display size, background color, and device type, etc.) and general operation methods (such as pressing the left button, selecting and moving, etc.);

[0121] Step5: Create a class for the fan equipment model, and define the properties of the class (such as current angle, rotation speed and rotati...

Embodiment 2

[0141] Step1: Use 3D design software (such as SolidWorks) to disassemble and model the lithium battery, and design each component of the lithium battery in turn, including: box, hinge, cover, upper baffle and lower baffle, etc., to form multiple component files (such as box.SLDPRT);

[0142] Step2: Assemble and merge the components of each lithium battery into an assembly (such as lithium battery.SLDASM), and then export the assembly as a lithium battery model file (such as lithium battery_old.xaml);

[0143] Step3: Optimize the exported lithium battery model file, and use the defined model template to generate an optimized model file (such as lithium battery.xaml);

[0144] Step4: Create an interface of a 3D model, and define the general properties of the interface (such as display size, background color, and device type, etc.) and general operation methods (such as pressing the left button, selecting and moving, etc.);

[0145] Step5: Create a class for the lithium battery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com