Repairing and reinforcing method for partition type outer wall outer heat insulation system

A technology for external insulation, repair and reinforcement of external walls, applied in building maintenance, construction, building construction, etc., can solve the problems of large construction area, long period, large impact, etc., and achieve small renovation area, convenient construction, and small impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

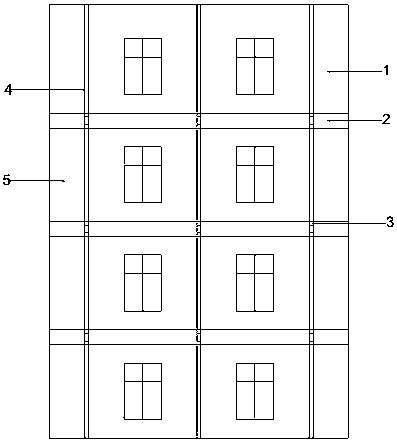

[0026] A method for repairing and strengthening the external thermal insulation of a compartmentalized exterior wall, comprising the following steps:

[0027] (1) On the original outer wall 1, cut out a plurality of horizontal strip-shaped areas 2 with a height of 20cm at equal intervals, cut to the base wall, remove the original insulation system, and clean it up. Interface treatment, the spacing of the transverse band zone 2 is 2.8m;

[0028] (2) Use ready-mixed mortar DPM10 to paint multiple rectangular mortar blocks 3 with a size of 10cm*10cm in the horizontal strip area 2 at equal intervals of 0.5m, and the thickness is flush with the original external wall surface;

[0029] (3) Paint light-weight thermal insulation mortar on the rest of the horizontal strip area 2, and the thickness is flush with the original external wall;

[0030] (4) Lay the fiber cloth 4 with carbon fiber glue longitudinally along the position of the rectangular mortar block 3, and sprinkle sand on ...

Embodiment 2

[0036] A method for repairing and strengthening the external thermal insulation of a compartmentalized exterior wall, comprising the following steps:

[0037] (1) On the original outer wall 1, cut out a plurality of horizontal strip-shaped areas 2 with a height of 25cm at equal intervals, cut to the base wall, remove the original insulation system, and clean it up. The horizontal strip-shaped areas 2 are painted with interface agent Interface treatment, the spacing of the transverse bands is 3m;

[0038] (2) Use ready-mixed mortar DPM15 to paint multiple rectangular mortar blocks 3 with a size of 10cm*10cm in the horizontal strip area 2 at equal intervals of 1m, and the thickness is flush with the original external wall surface;

[0039] (3) Paint light-weight thermal insulation mortar on the rest of the horizontal strip area 2, and the thickness is flush with the original external wall;

[0040] (4) Lay the fiber cloth 4 with carbon fiber glue longitudinally along the positi...

Embodiment 3

[0046] A method for repairing and strengthening the external thermal insulation of a compartmentalized exterior wall, comprising the following steps:

[0047] (1) On the original outer wall 1, cut out multiple horizontal strip-shaped areas 2 with a height of 30cm at equal intervals, cut to the base wall, remove the original insulation system, and clean it up. Interface treatment, the spacing of the transverse bands is 3.2m;

[0048] (2) Use ready-mixed mortar DPM10 to paint multiple rectangular mortar blocks 3 with a size of 10cm*10cm in the horizontal strip area 2 at equal intervals of 0.5m, and the thickness is flush with the original external wall surface;

[0049] (3) Paint light-weight thermal insulation mortar on the rest of the horizontal strip area 2, and the thickness is flush with the original external wall;

[0050] (4) Lay the fiber cloth 4 with carbon fiber glue longitudinally along the position of the rectangular mortar block 3, and sprinkle sand on the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com